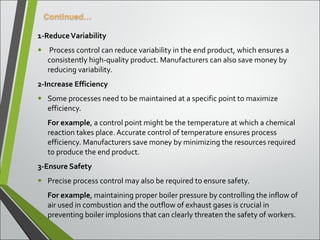

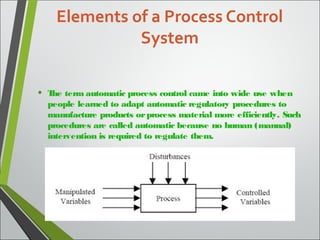

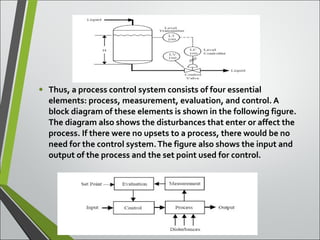

Control in process industries is important to precisely regulate all aspects of manufacturing processes. This involves controlling variables like temperature, pressure, flow and level. Process control technology helps manufacturers keep operations running safely and efficiently within specified limits to maximize quality and profitability. It works by measuring process variables, evaluating measurements against set points, and controlling variables through manipulated elements like valves. This ensures consistent products despite disturbances.