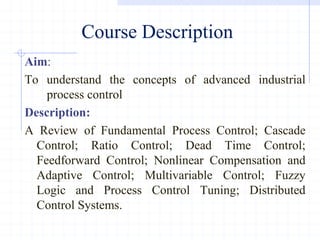

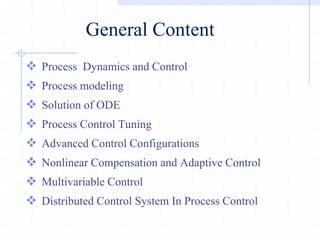

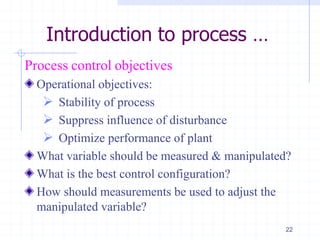

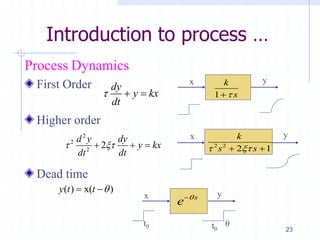

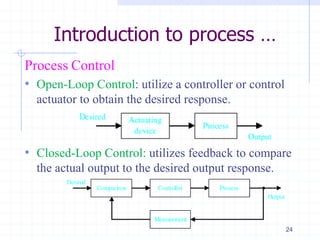

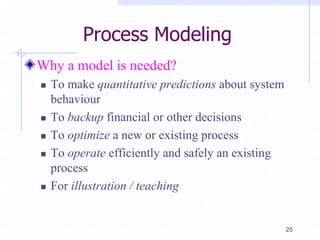

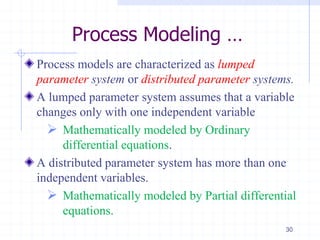

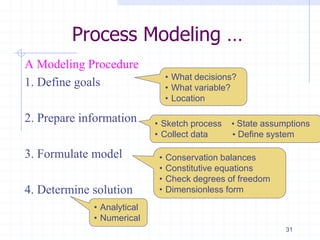

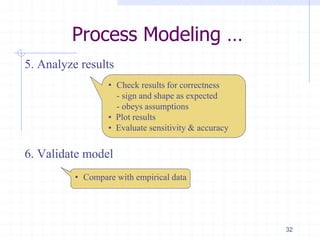

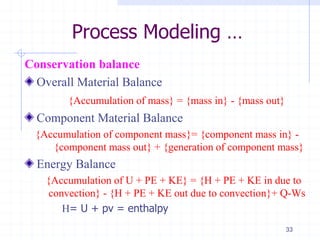

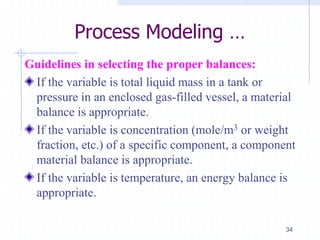

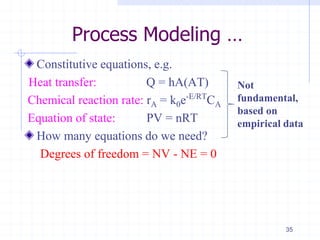

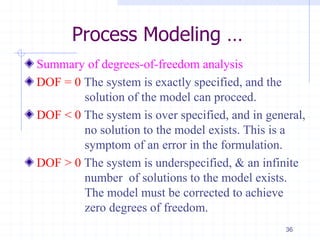

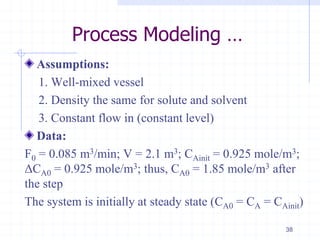

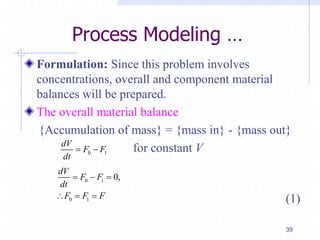

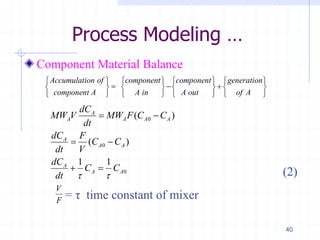

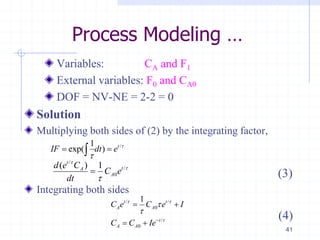

This document provides an overview of a course on advanced process control fundamentals. The course aims to understand concepts of advanced industrial process control. Topics covered include process dynamics and control, process modeling, solution of differential equations, advanced control configurations, nonlinear compensation, multivariable control, and distributed control systems. Prerequisites for the course are several introductory control systems courses. The first lecture provides an introduction to process dynamics and control, including modeling a process, process control objectives, and the first order dynamics of processes. Process modeling involves formulating material and energy balances, developing constitutive equations, and ensuring the appropriate degrees of freedom.

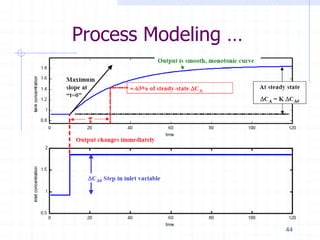

![Process Modeling …

Results Analysis

43

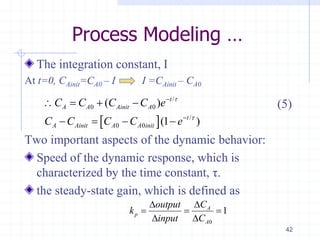

Time

from step

Percent of final steady-

state change in output

0 0

T 63.2

2T 86.2

3T 95

4T 98.2

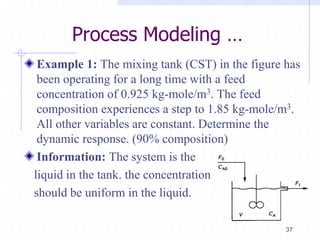

The goal statement

involves determining

the time until 90 % of

the change in outlet

concentration has

occurred.

This time can be calculated by setting

CA = CAinit + 0.9(CA0 - CAinit) in eqn. (5) and solving

Ainit A0

Ainit A0

0.1[ ]

ln (24.7)( 2.3) 56.8min

C C

t

C C

](https://image.slidesharecdn.com/ep-5512lecture-01-190313233546/85/Ep-5512-lecture-01-43-320.jpg)