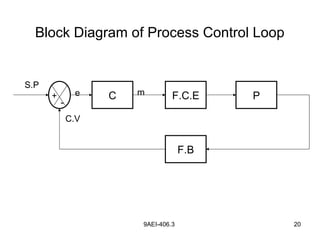

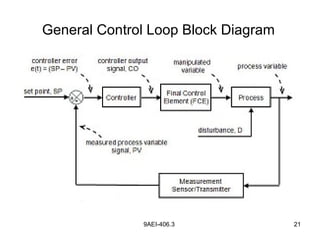

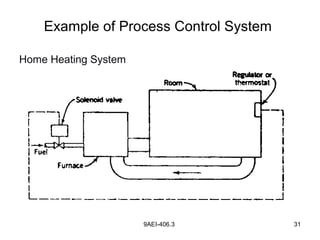

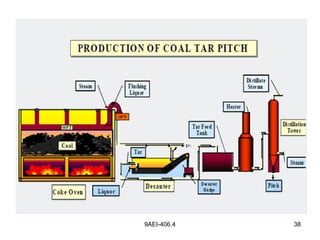

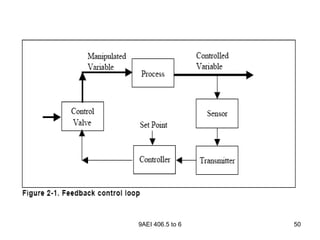

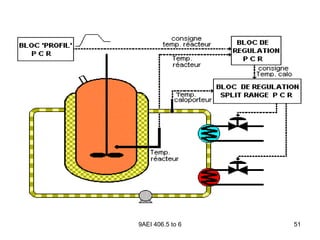

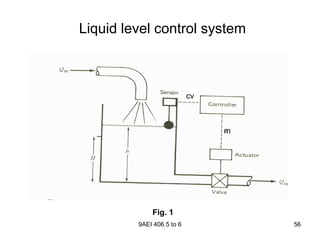

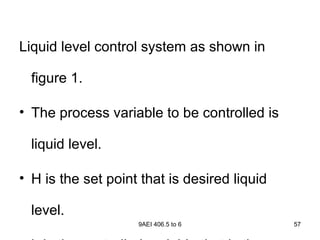

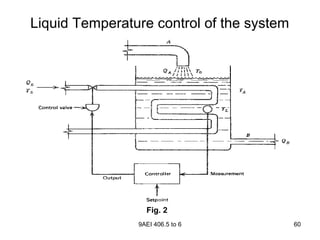

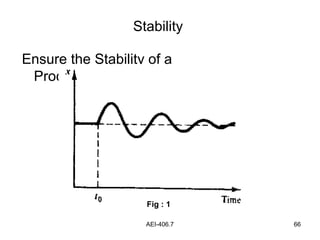

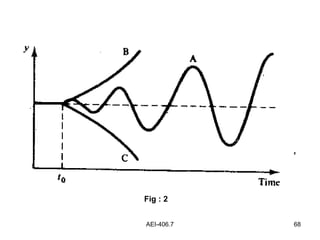

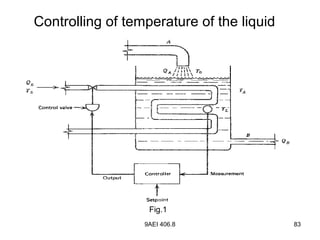

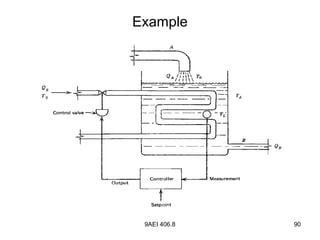

This document provides an introduction to process control. It defines a process as an operation that transforms raw materials into a more useful state. The objectives of process control are to produce desired outputs from inputs in the most economical way. Processes can be described by differential equations and are affected by various internal and external conditions. Effective process control requires maintaining safety, meeting production specifications, and optimizing economics while addressing changing external influences. Examples of processes include unit operations in chemical plants and manufacturing units. The document outlines the basic components of a process control system and loop.