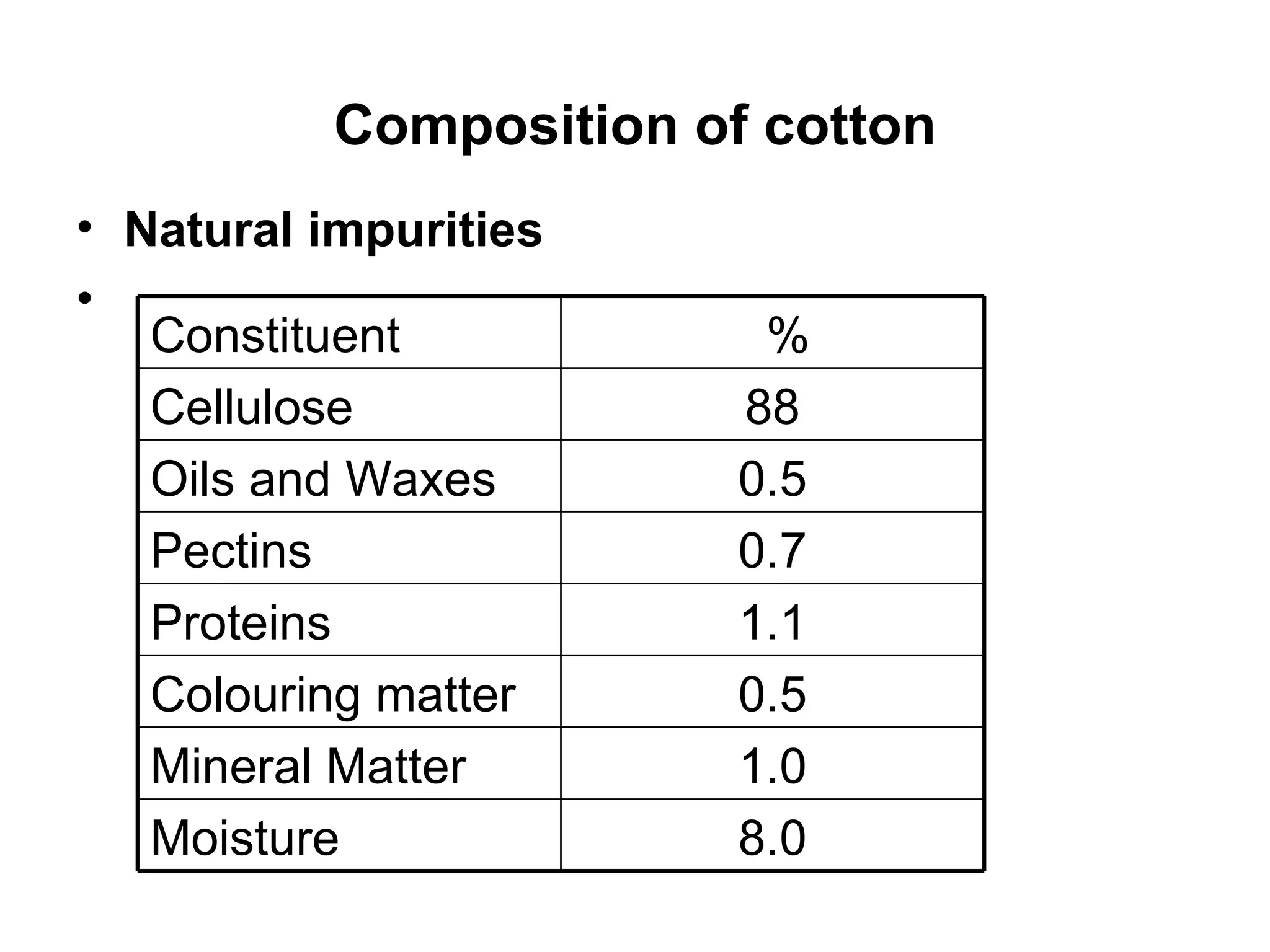

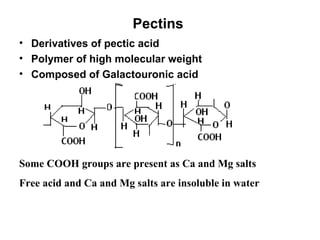

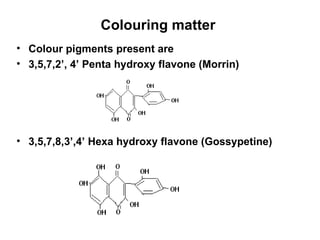

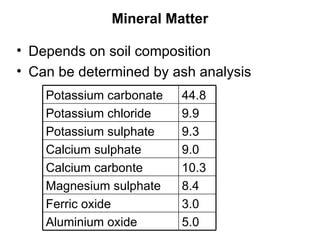

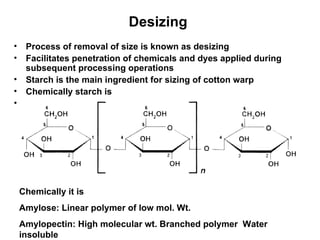

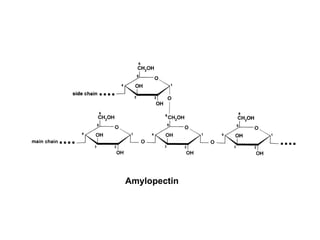

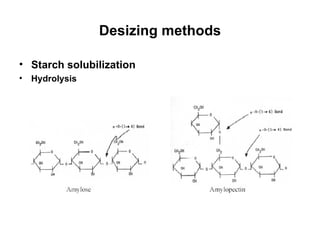

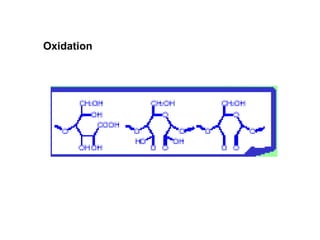

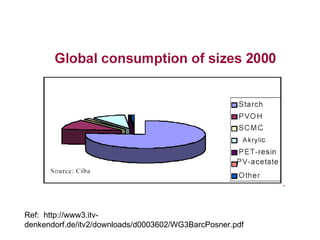

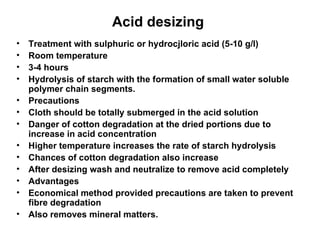

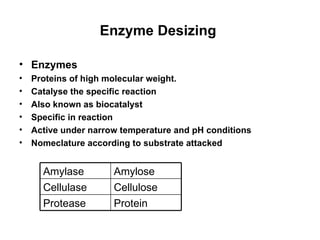

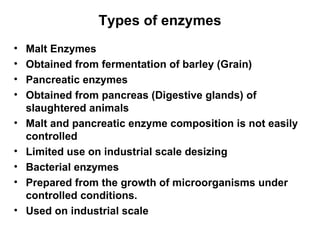

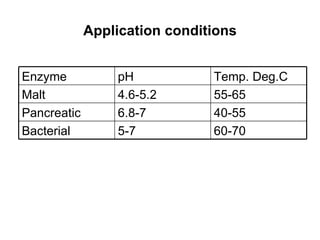

The document discusses the composition and constituents of cotton, including natural impurities, fats and waxes, pectins, proteins, colouring matter, and mineral matter. It also discusses added impurities from sizing agents used in weaving. The purpose of preparatory processes is to remove impurities from cotton to impart desirable properties. Desizing is the process of removing size, which facilitates further processing by making starch water soluble through hydrolysis, oxidation, or enzymatic reactions. Common desizing methods include acid desizing, enzyme desizing, and oxidative desizing.