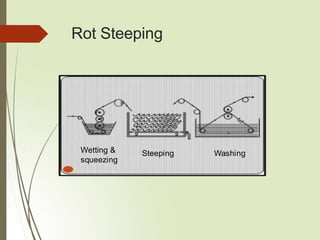

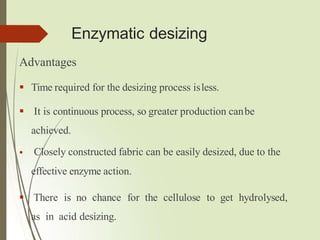

Desizing is the process of removing starch sizes from warp yarns after weaving. The key methods are rot steeping, acidic desizing using dilute acid, enzymatic desizing using starch-hydrolyzing enzymes, and oxidative desizing using oxidizing agents. Rot steeping is the oldest method but is slow, while enzymatic desizing is now widely used as it efficiently removes sizes under mild conditions without damaging fibers. Acidic and oxidative desizing can also work but may damage fibers if not properly controlled. The Tegewa violet scale is commonly used to assess desizing efficiency by checking for color changes from starch residues on fabrics.

![Assessment of desizing efficiency

TEGEWA violetscale

Reagent preparation

Put potassium iodide [10g of KI (100%)] in 100 ml of water; then add 0.6358 g of iodine (100%);

stir well until iodine is completely dissolved in the KI solution. After this, add 800 ml

of ethanol. Then by adding water the volume should be raised to 1000 ml.

Method of testing

Put one or twodrops of the above solution on a fabric. Rub it gently and then assess the colour

change as per the Tegewa scale. Before testing, the fabric should be coldand

thereshould not be any residual alkalinity in it.

Assessment

No Colour Change = No starch is present

Pale blue to bluish violet = Presence of starch size or a blend of starch+ synthetic size

Brown = Presence of modified starch or a blend of starch/PVA size](https://image.slidesharecdn.com/textiledesizingslide-220622073122-2ce7a512/85/Textile-Desizing-Slide-pptx-19-320.jpg)