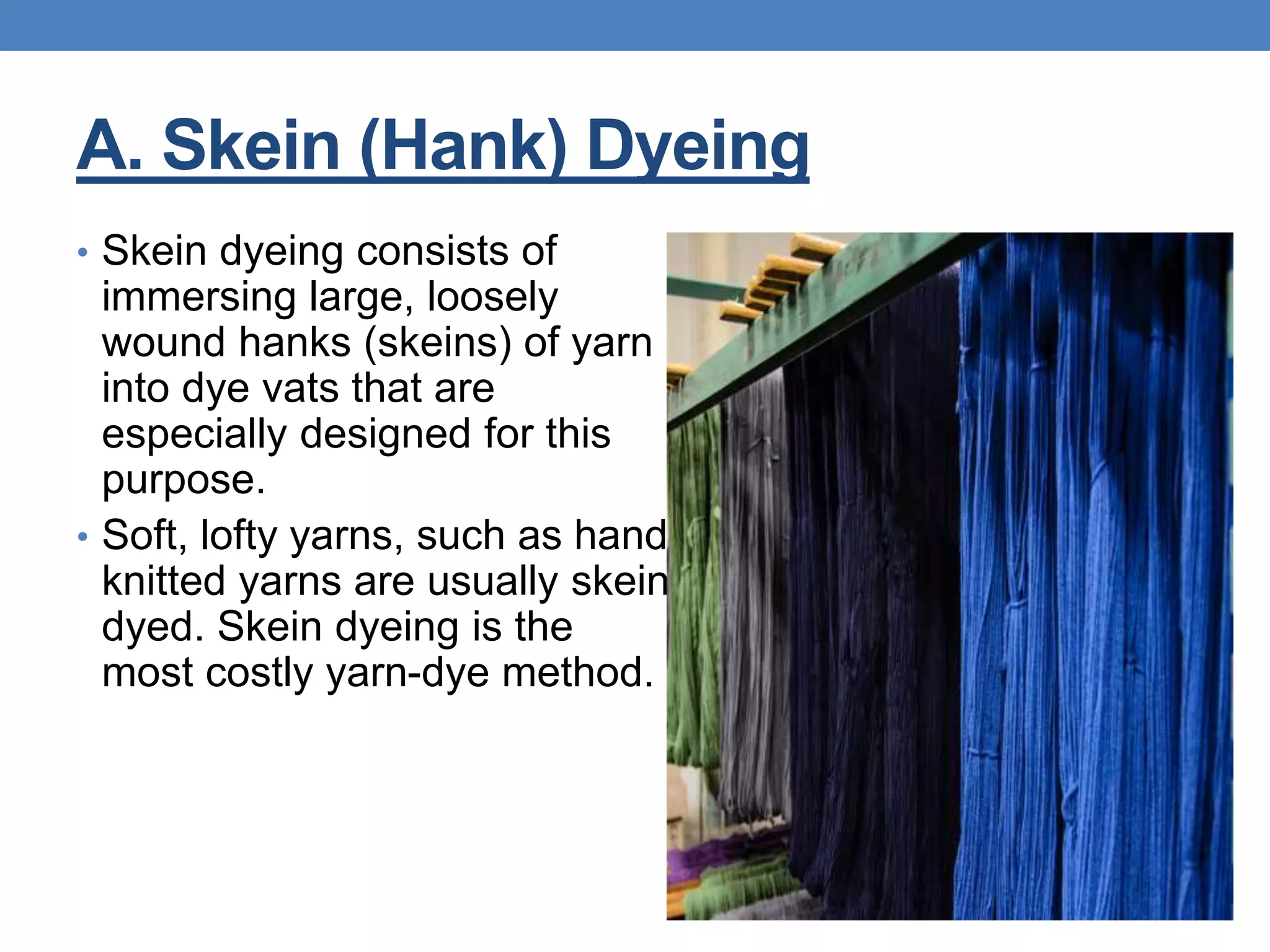

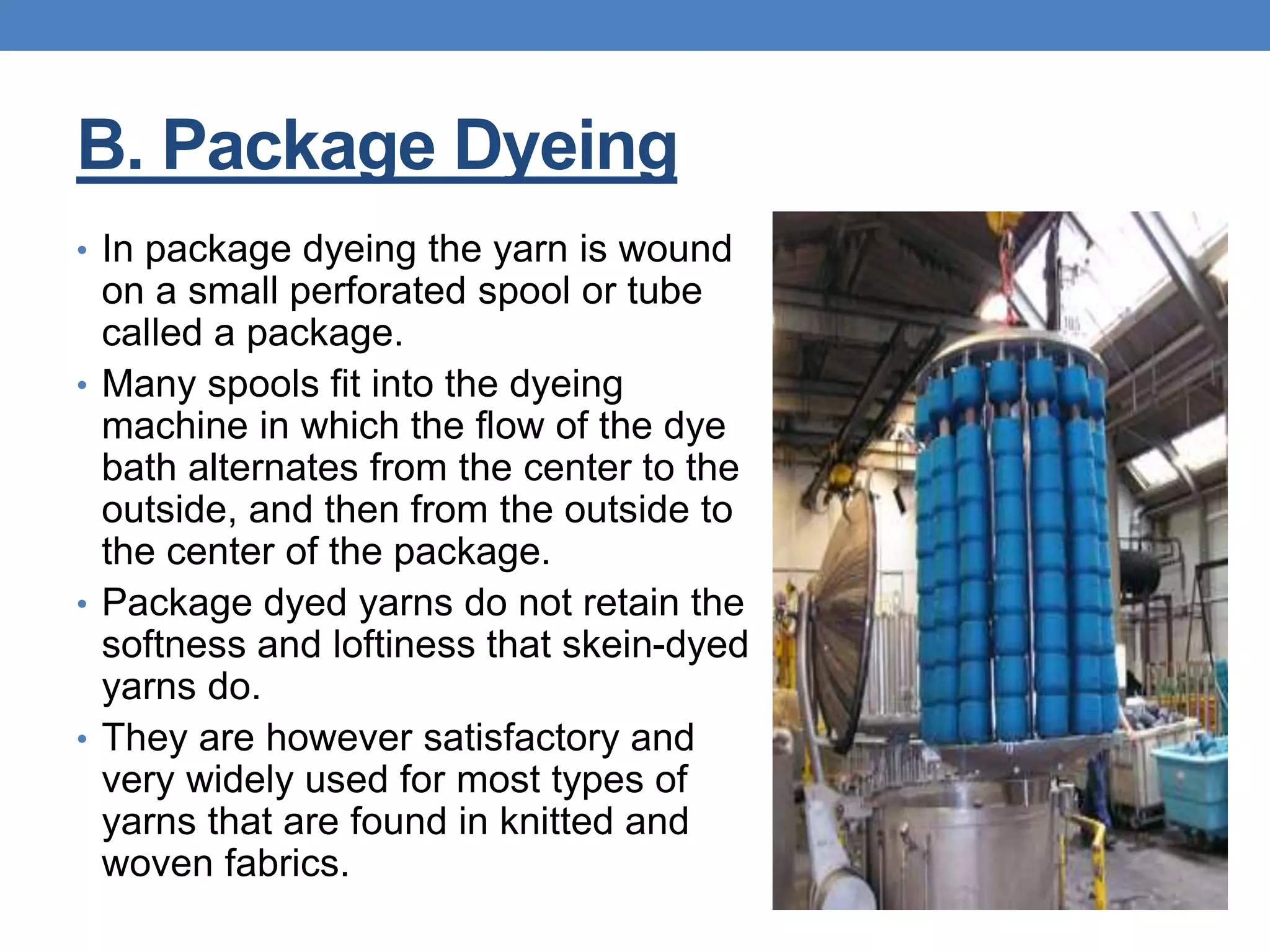

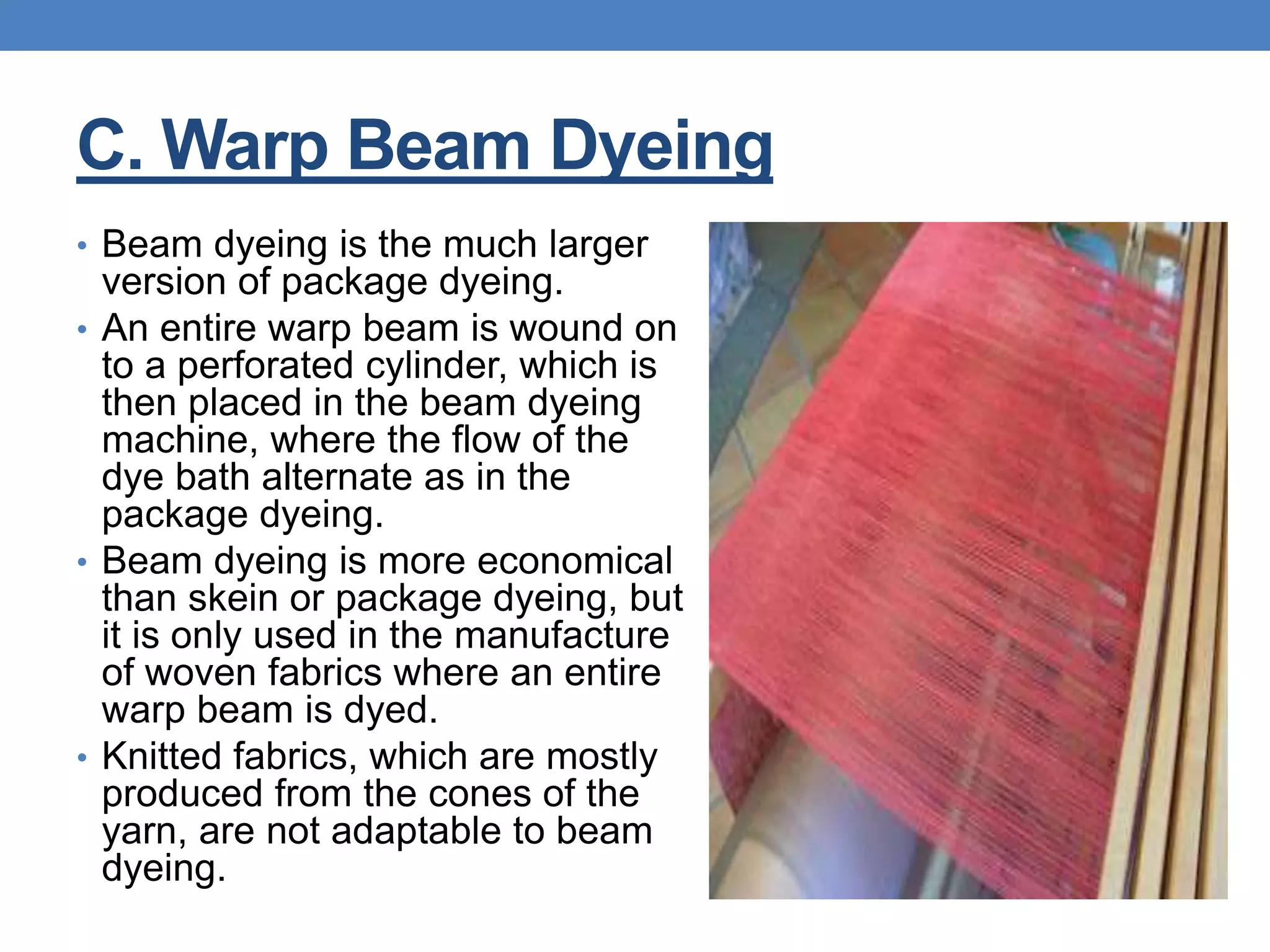

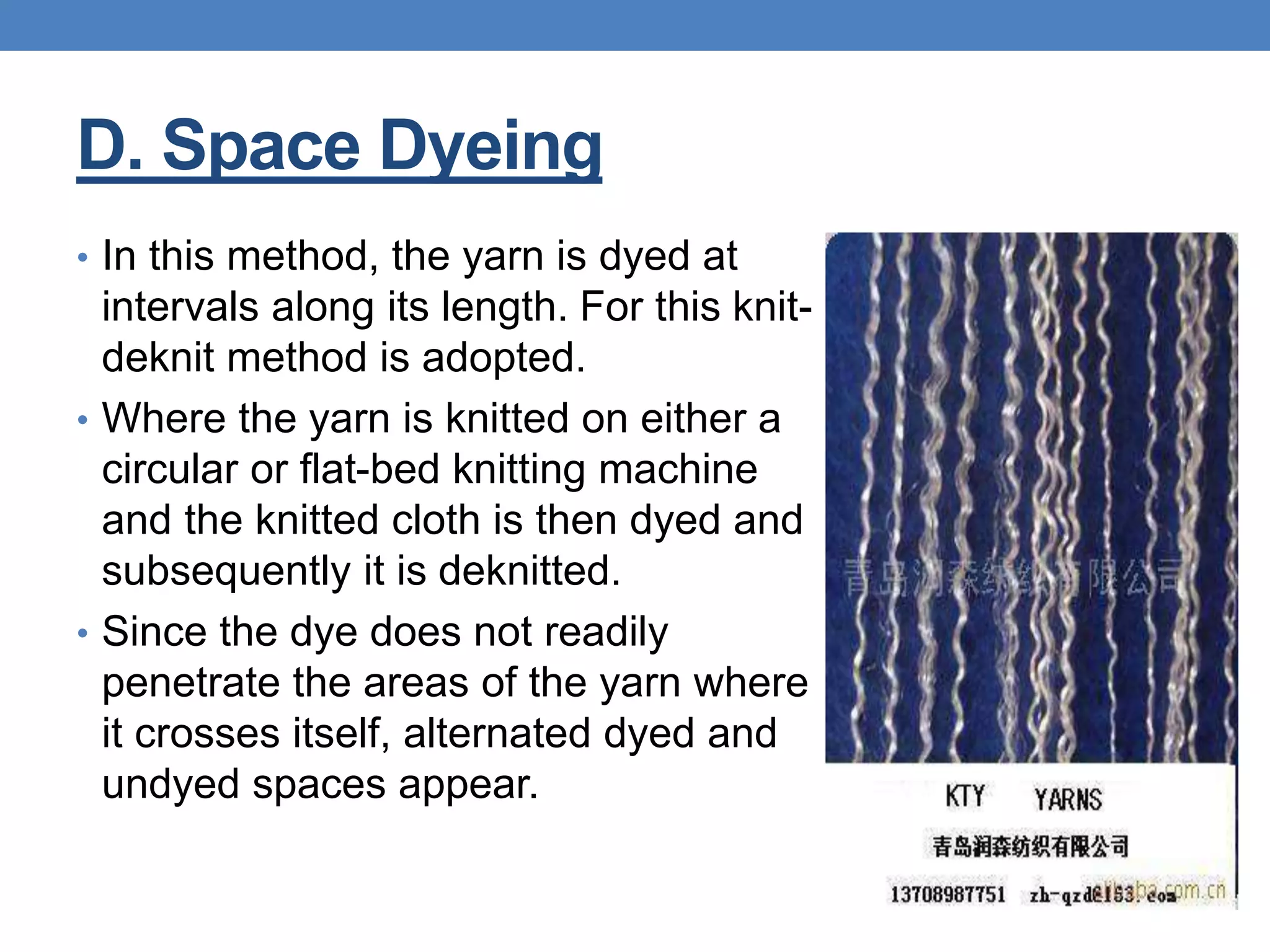

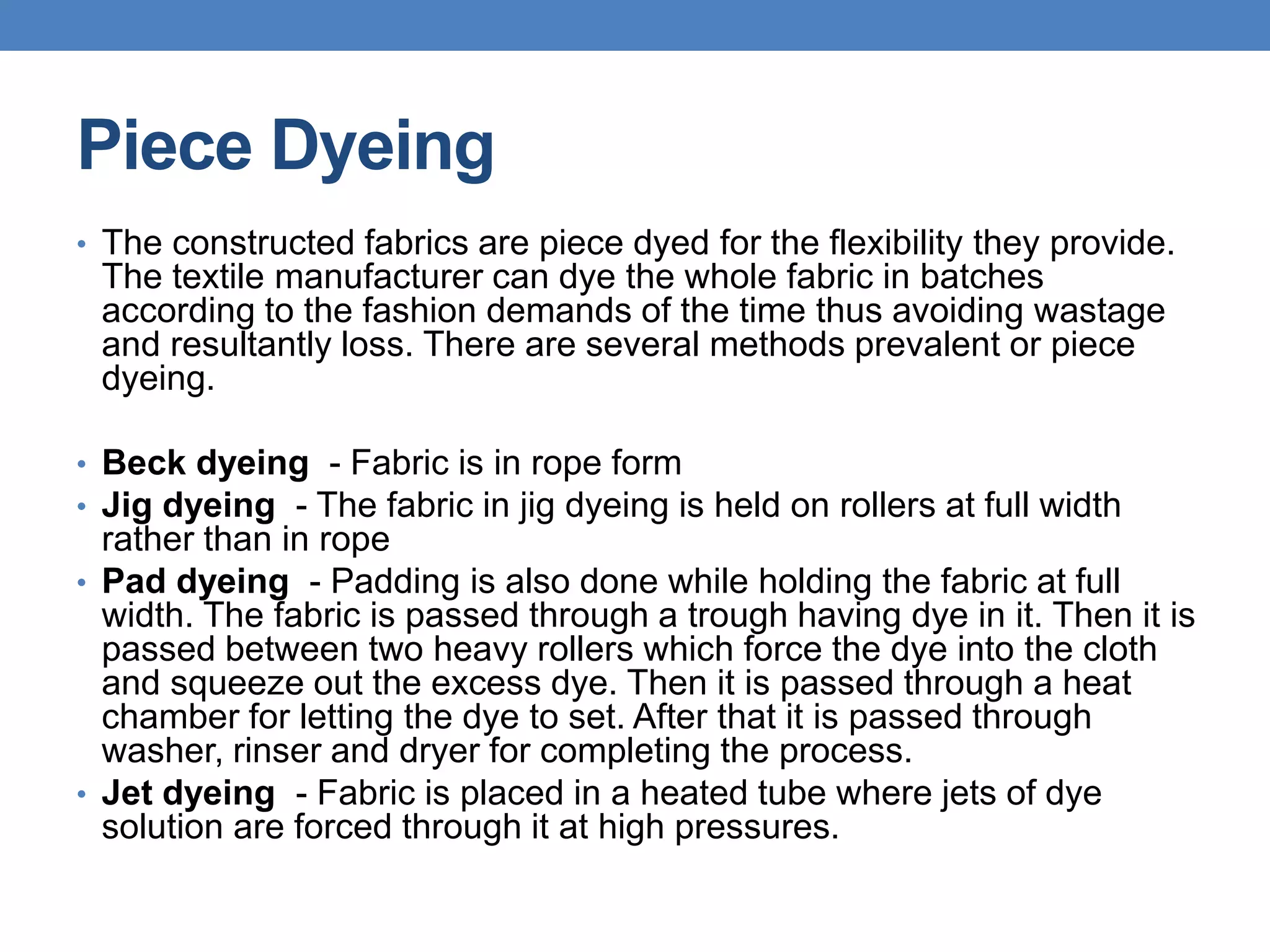

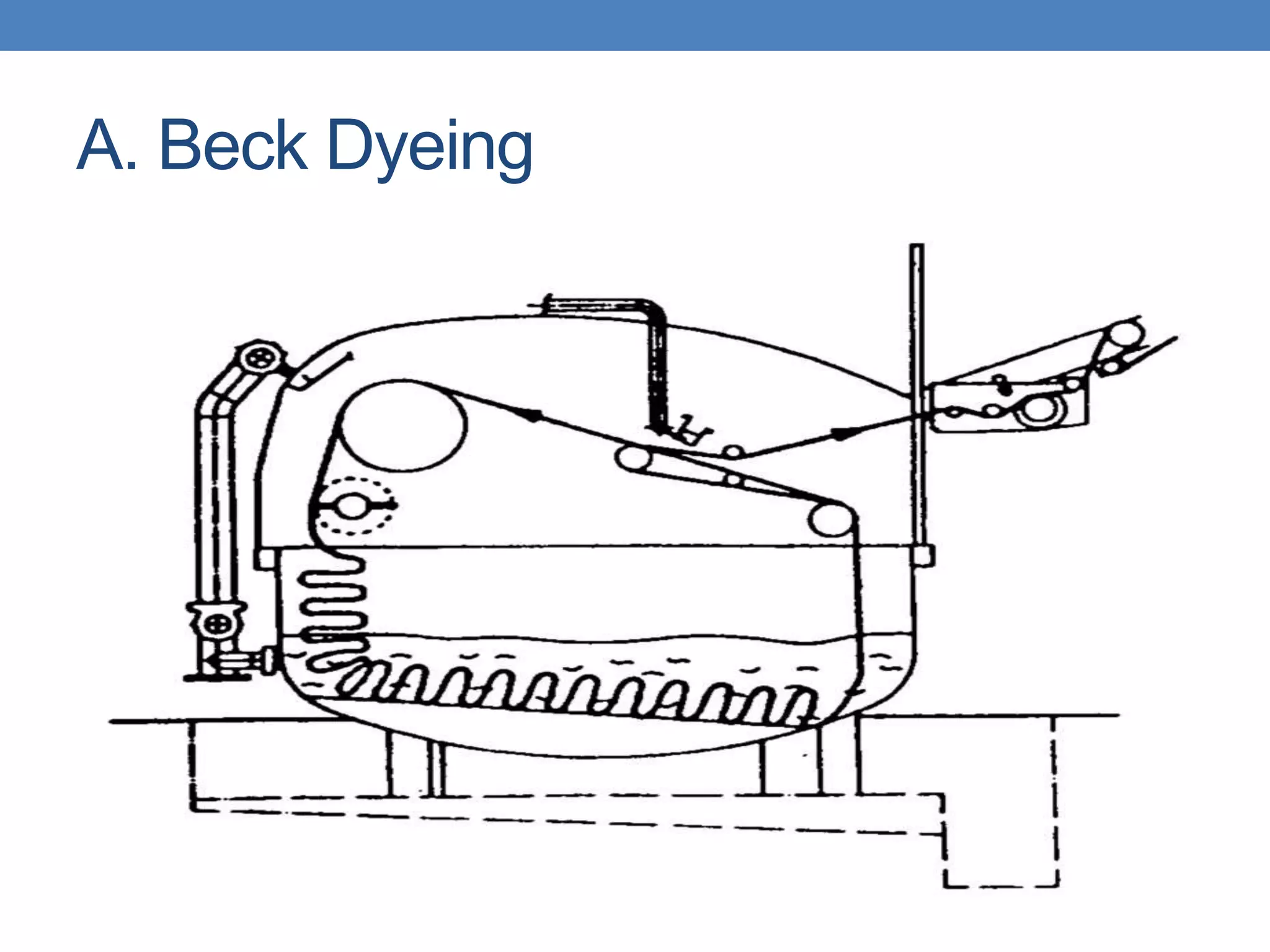

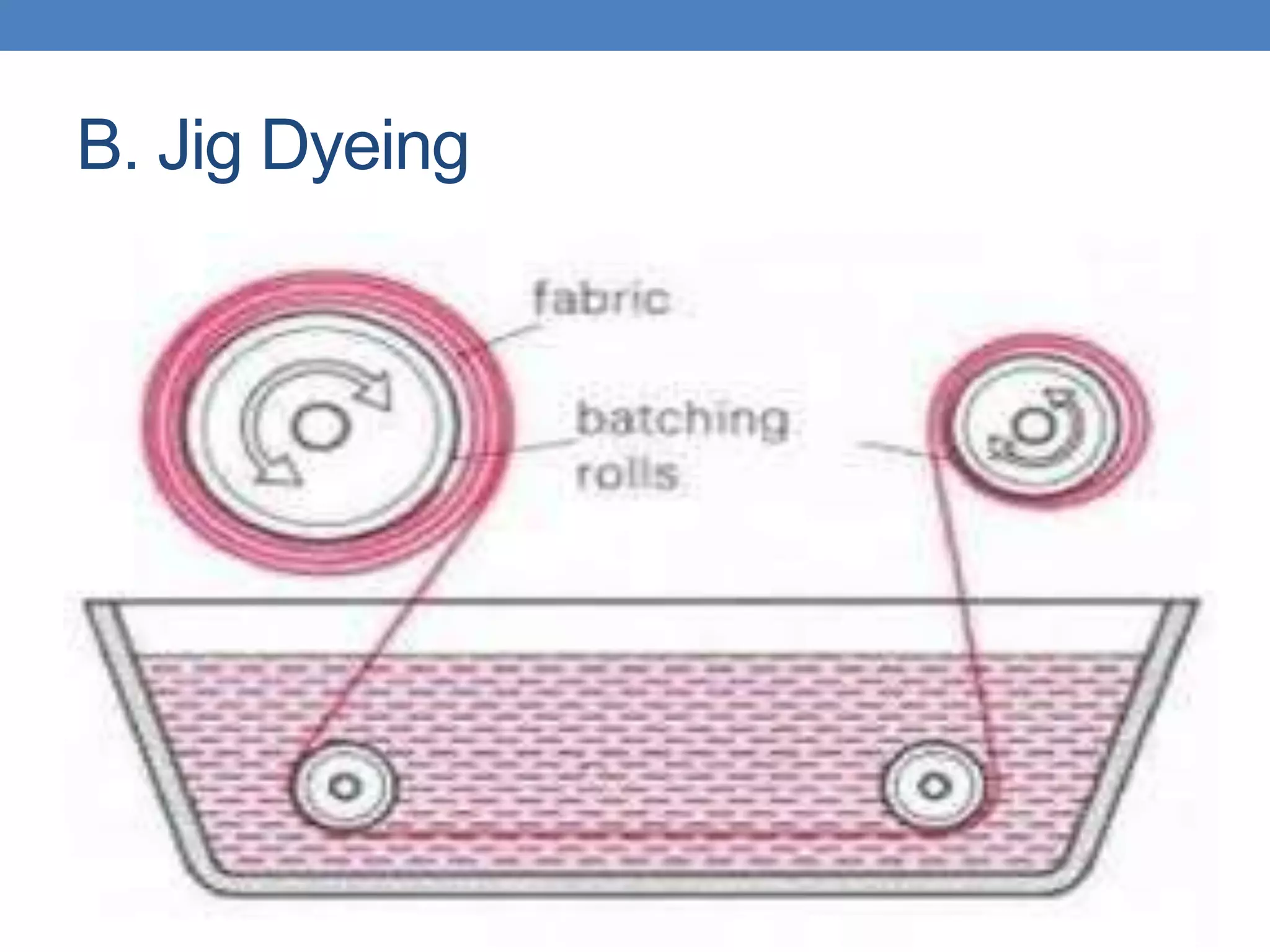

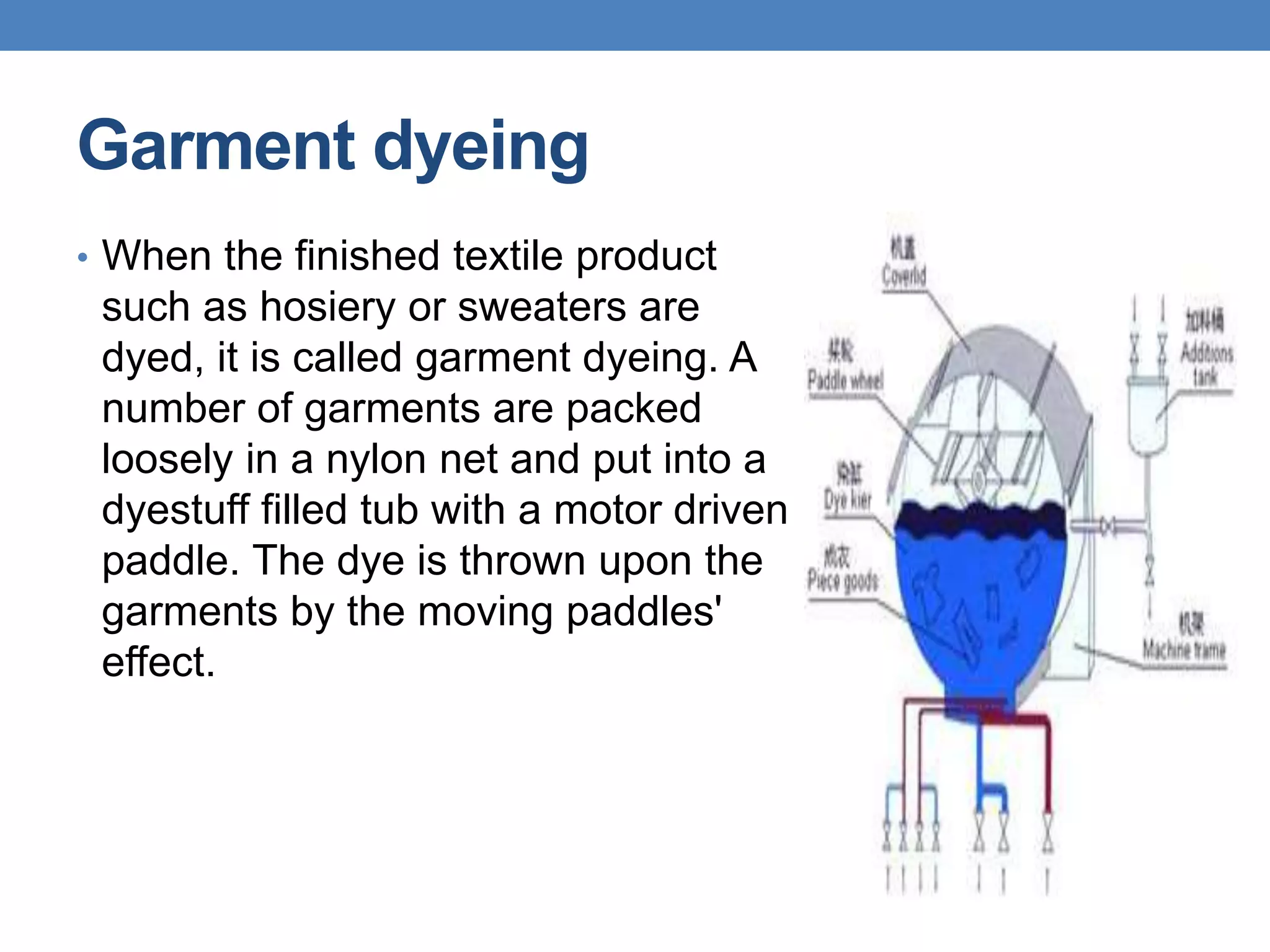

The document provides an overview of different textile manufacturing processes, focusing on fabric coloration methods. It discusses the two main methods - dyeing and printing. For dyeing, it describes different dye types and dyeing processes like direct dyeing, stock dyeing, yarn dyeing, and piece dyeing. It provides details on each process and the types of fabrics they are suited for. The summary highlights the key coloration methods covered in the document.