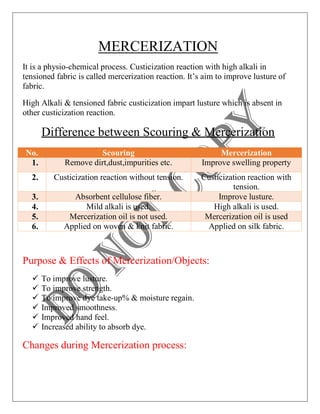

Mercerization is a physio-chemical process that improves the luster of fabrics like cotton and silk. It involves treating tensioned fabric with a high concentration of alkali such as sodium hydroxide. This causes a custicization reaction that changes the cellulose structure from Cellulose I to Cellulose II, improving luster, strength, and dye uptake. There are different types of mercerization processes including tension, slack, hot, and liquid ammonia methods. The goal is to swell and alter the cellulose fibers for enhanced properties.