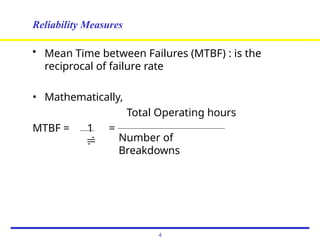

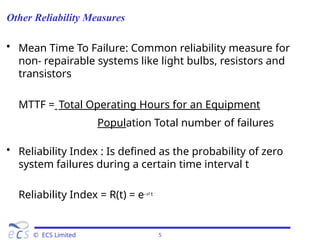

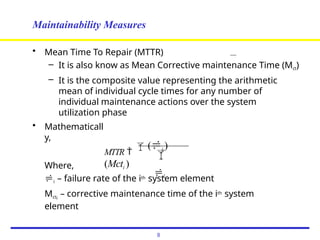

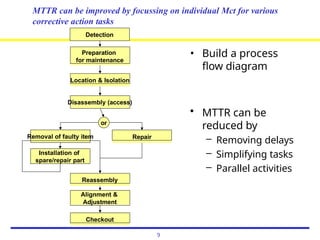

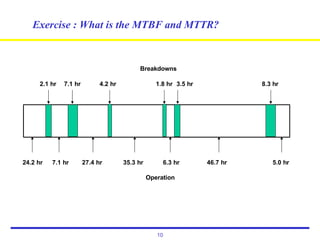

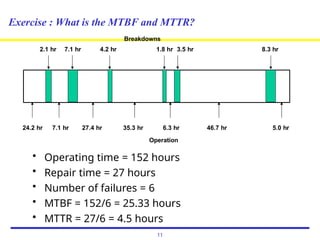

MTBF (Mean Time Between Failures) is the average operating time of a machine between one failure and the next, indicating how reliable the equipment is. MTTR (Mean Time To Repair) is the average time needed to repair a machine and return it to normal operation after a failure, reflecting maintenance efficiency. MTTF (Mean Time To Failure) is the average time a non-repairable component operates before it fails and must be replaced, showing the expected lifetime of the component. Together, these metrics are commonly used in maintenance and reliability management to evaluate equipment performance and improve reliability.