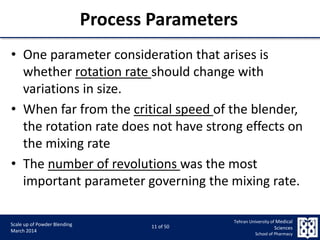

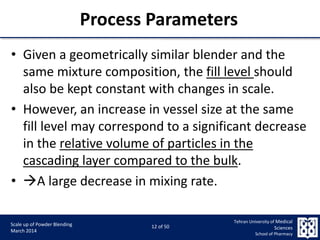

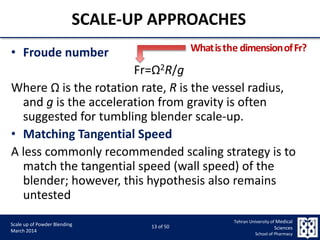

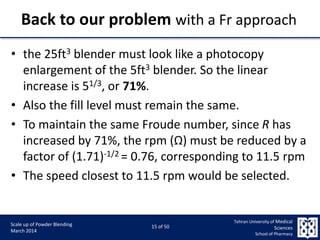

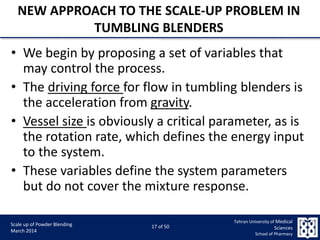

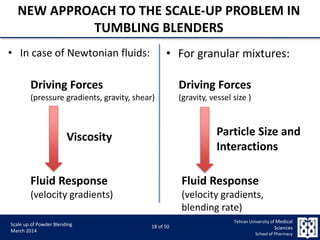

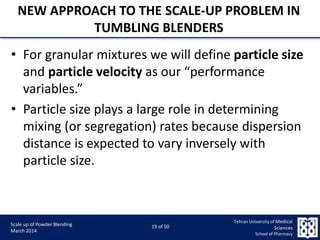

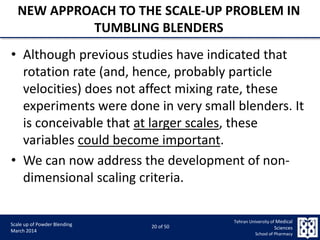

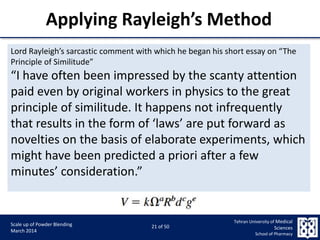

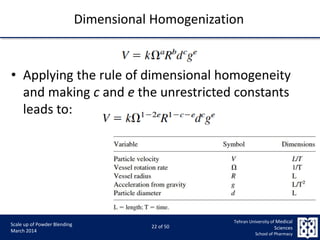

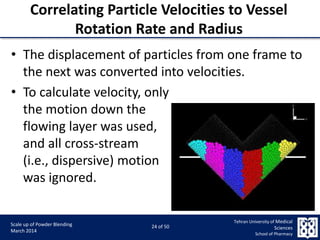

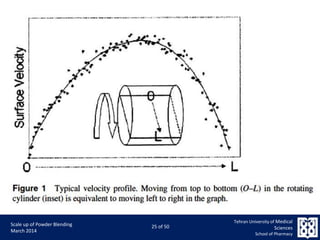

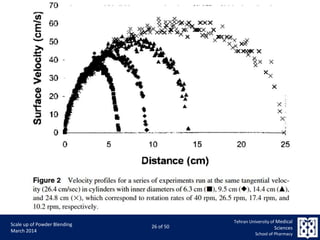

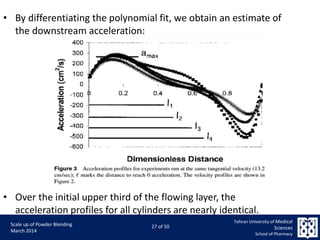

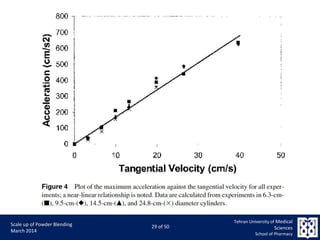

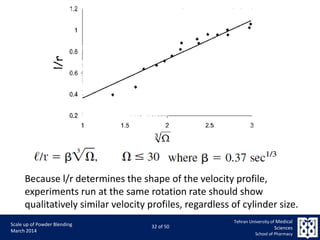

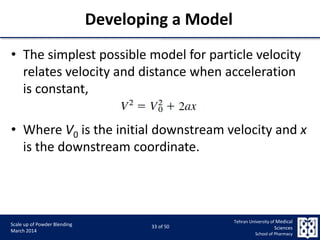

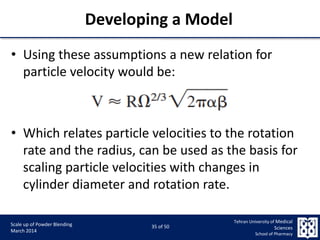

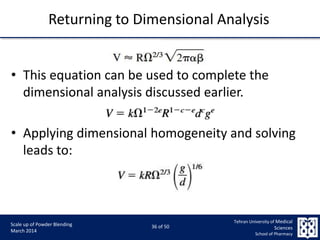

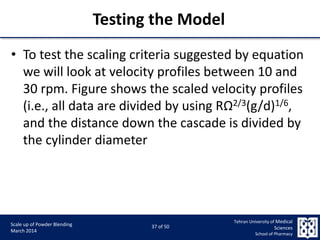

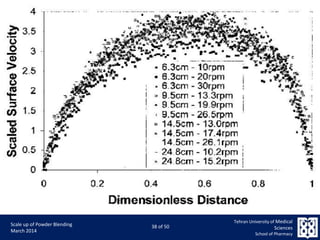

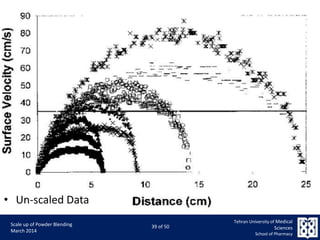

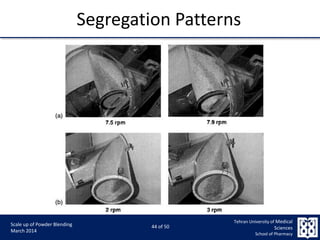

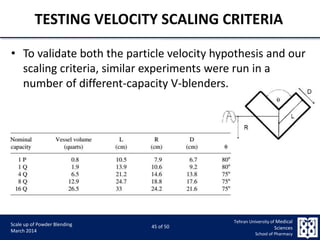

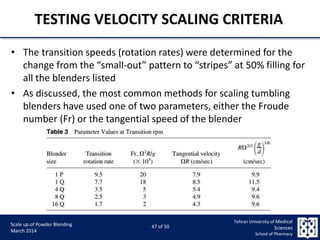

This document discusses the challenges and considerations in scaling up powder blending processes, particularly in tumbling blenders. It emphasizes the importance of achieving homogeneity and addresses various factors such as speed, load, and particle dynamics that influence blending effectiveness. The authors propose new models and scaling criteria to enhance understanding of mixture behavior during the scale-up of blending operations.