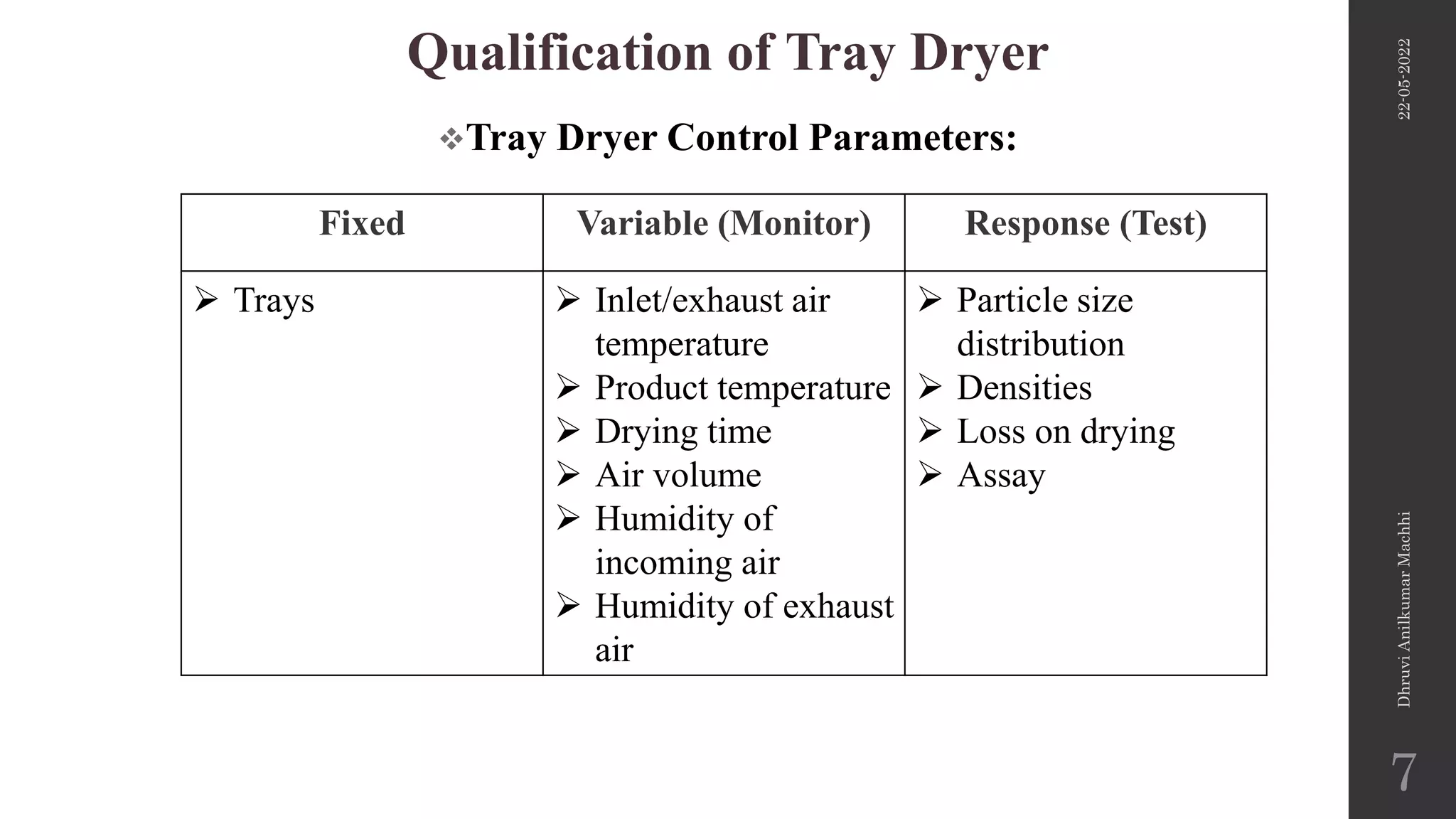

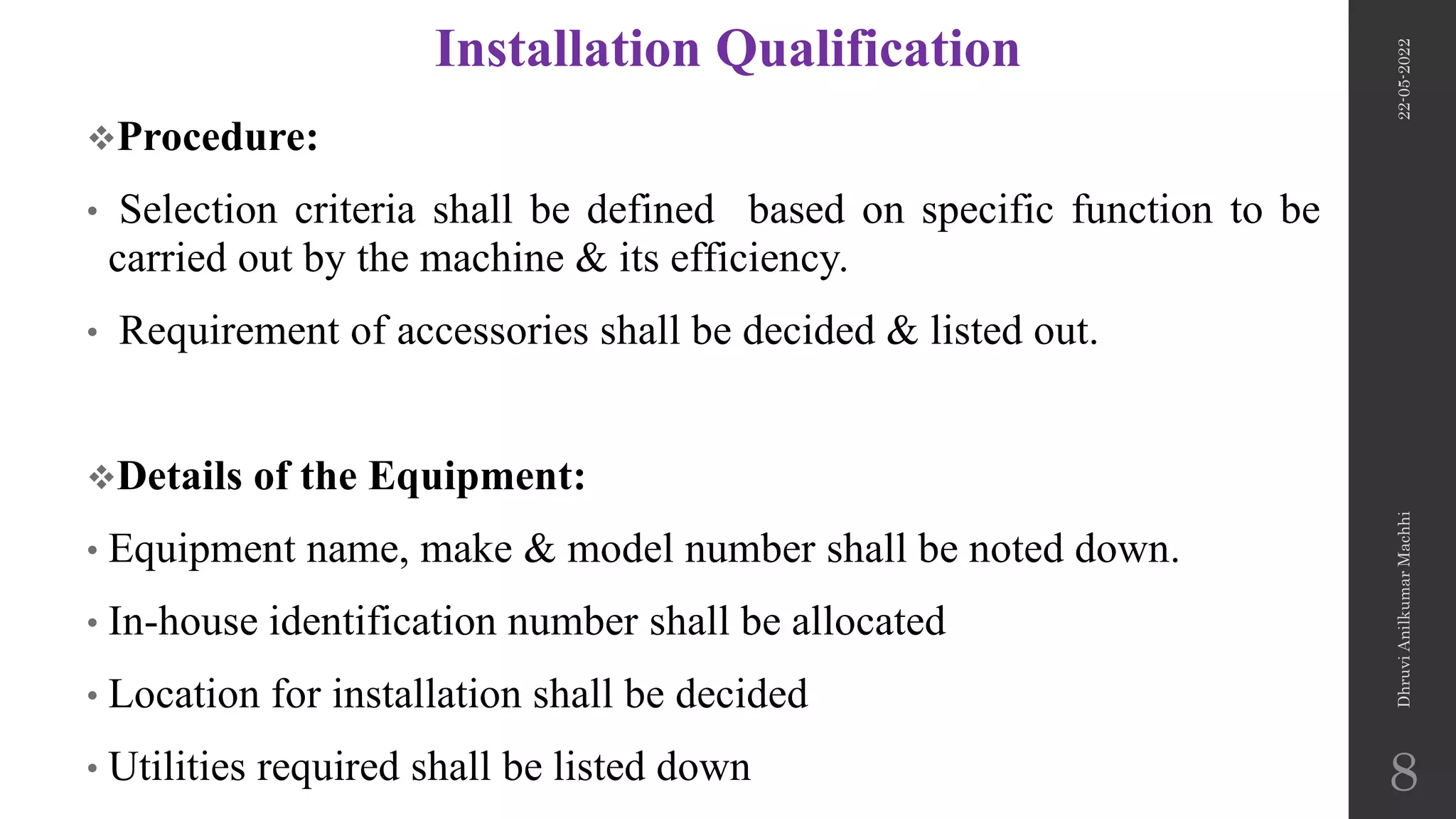

The document presents an overview of tray dryers used in pharmaceutical quality assurance, detailing their principles, construction, working mechanisms, qualifications, and performance testing. It explains how tray dryers operate through forced convection heating and the systematic qualification procedures to ensure efficient functioning. The text concludes with references for further reading on equipment qualification and pharmaceutical engineering practices.