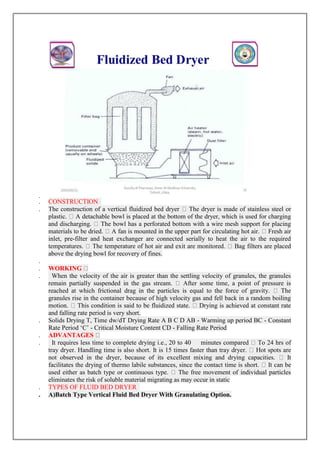

Fluidized bed dryers use hot air to fluidize granular materials for drying. Validation of fluidized bed dryers involves installation qualification to confirm proper installation, operational qualification to verify functionality across operating ranges, and performance qualification to demonstrate consistent production of safe, high-quality product. Key steps in validation include testing air temperature distribution, inlet air quality and flow rate, uniformity of mixing and drying, and analyzing trial batches. Validation establishes that a process will reliably meet specifications.