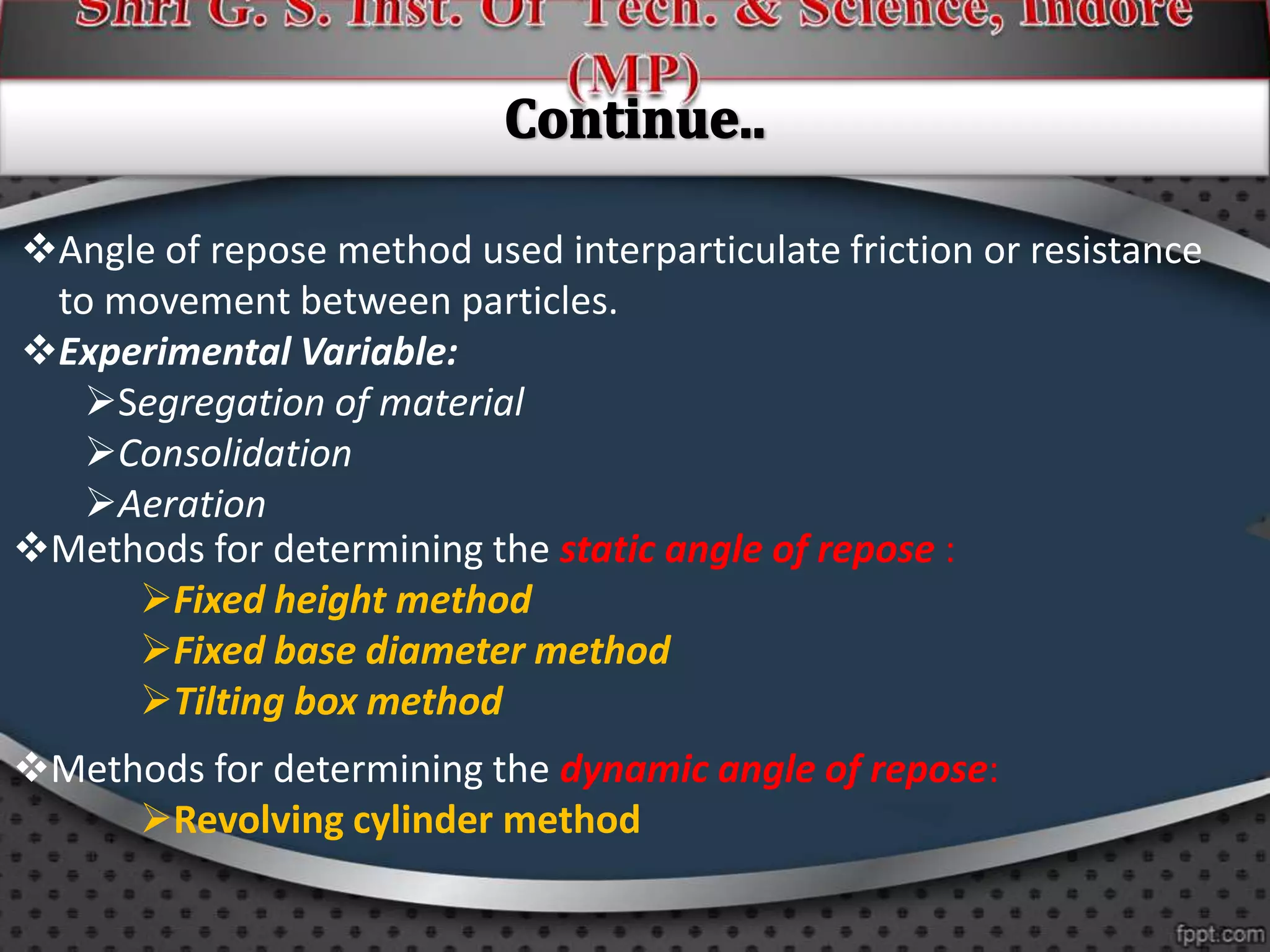

This document discusses powder flow properties which are important for pharmaceutical manufacturing processes. It defines different types of powder flow and factors that affect flow properties, such as particle size and moisture content. Several methods for measuring flow properties are described, including angle of repose, Carr's index, and shear cell testing. Maintaining consistent powder flow is crucial for uniformity in tablet and capsule production. Proper control and understanding of flow properties can improve process efficiency and product quality.