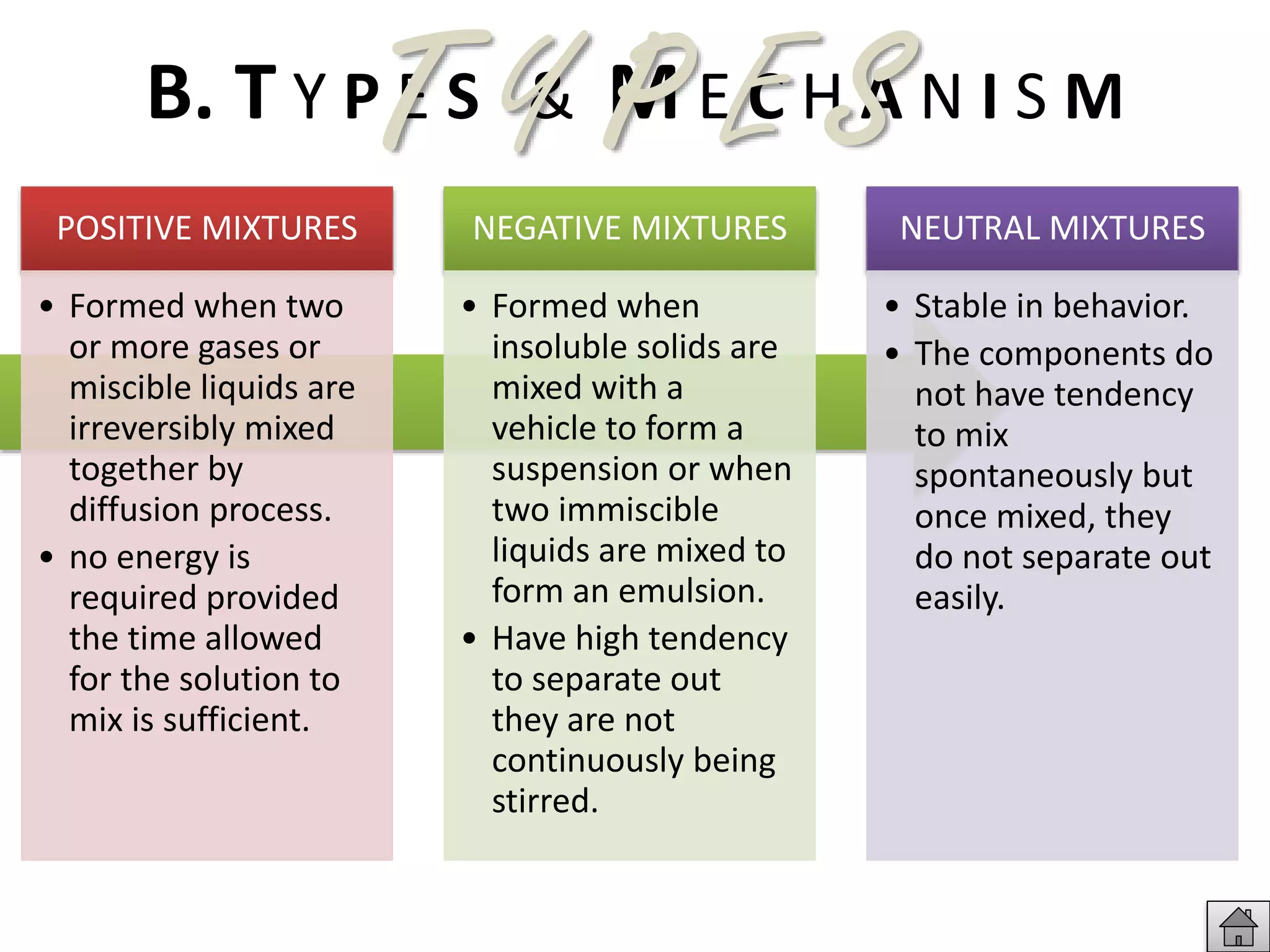

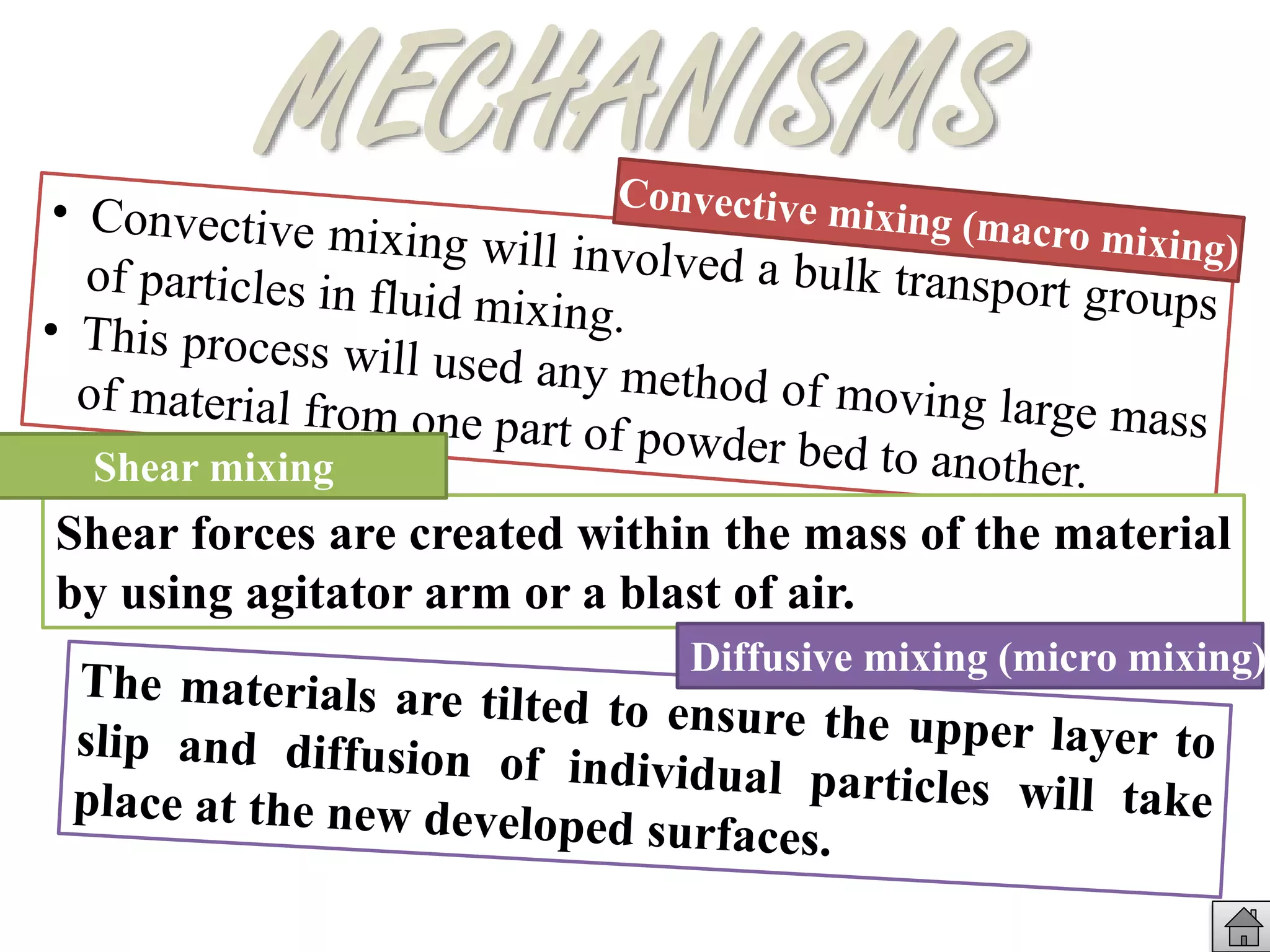

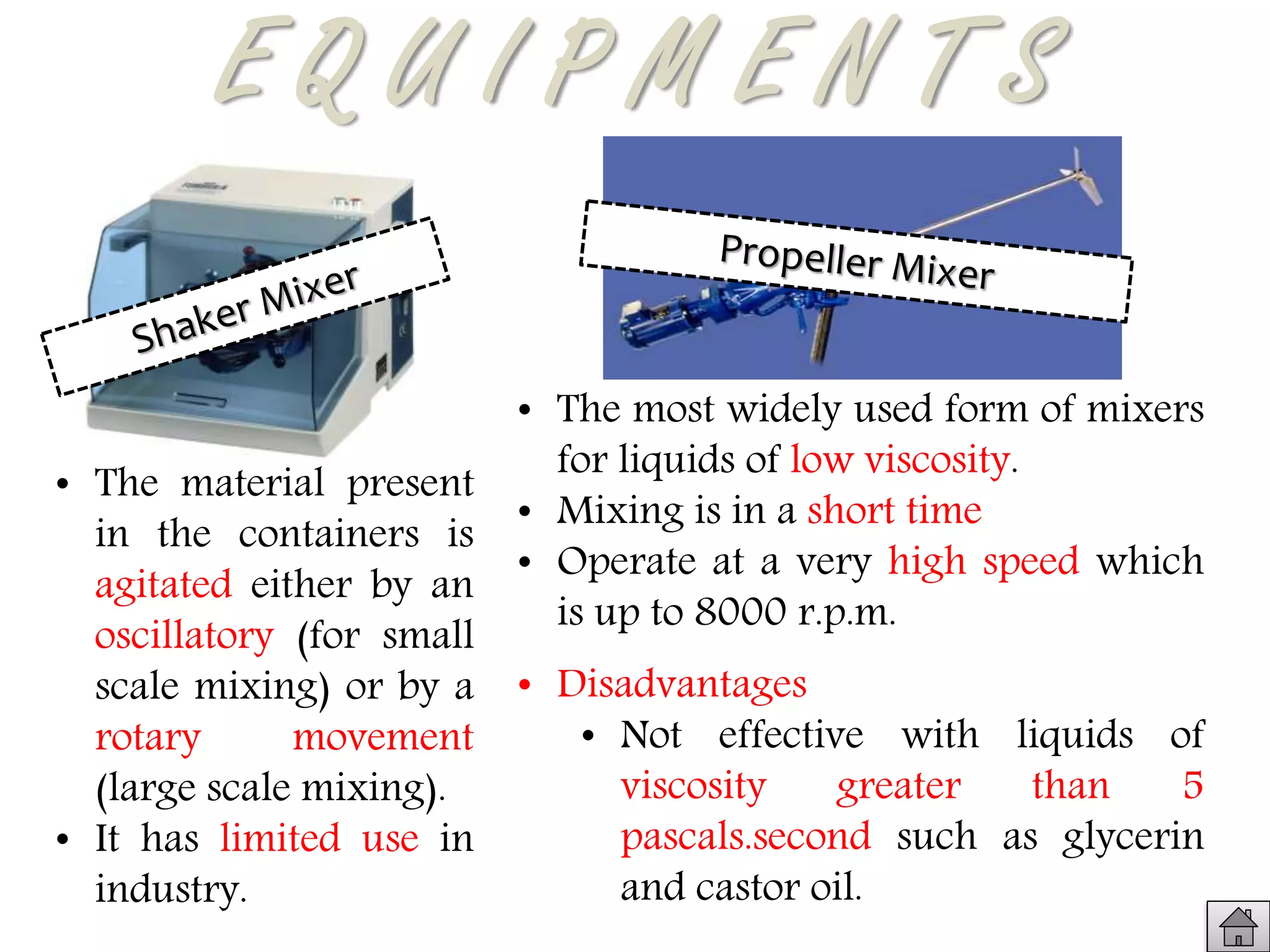

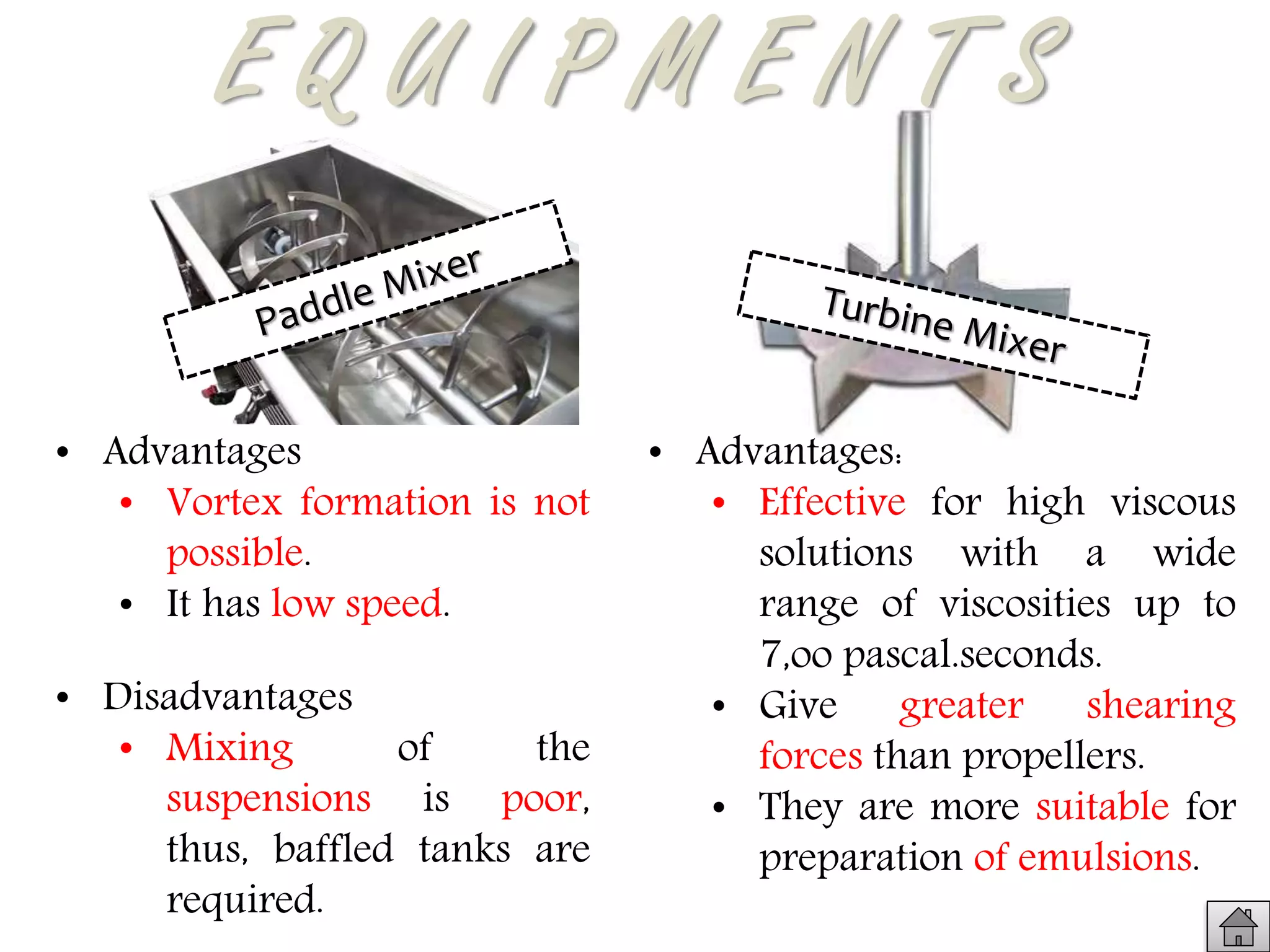

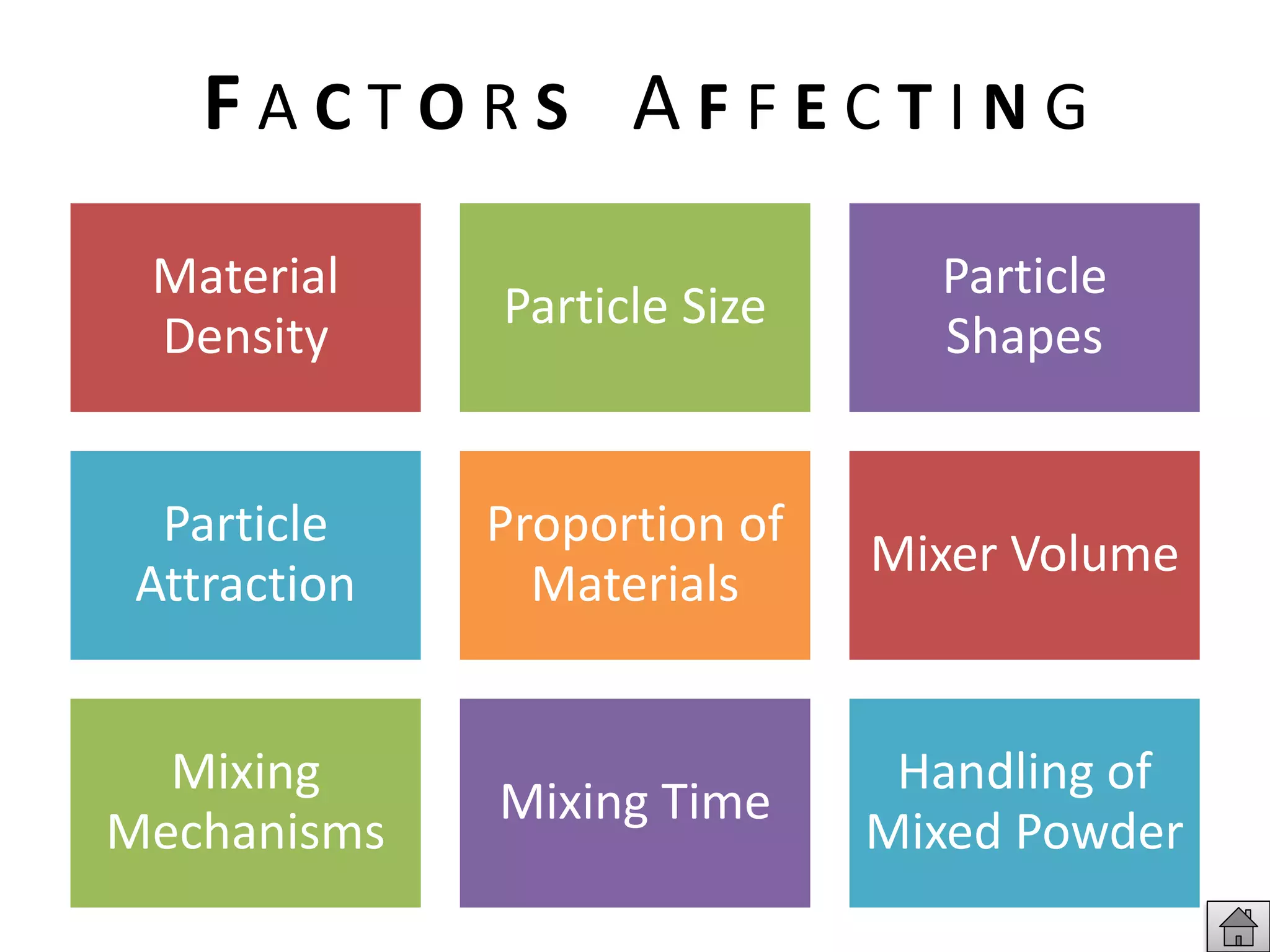

The document discusses the principles and techniques of mixing in pharmaceutical engineering, focusing on types of mixtures, including positive, negative, and neutral mixtures. It outlines the mechanisms of liquid, solid, and semi-solid mixing, including various mixing equipment and their advantages and disadvantages. Additionally, it highlights the importance of proper mixing to ensure homogeneity and consistency in pharmaceutical products.

![[Power Point] Mixing - Pharmaceutical Engineering](https://image.slidesharecdn.com/forslideshare-151107043333-lva1-app6892/75/Power-Point-Mixing-Pharmaceutical-Engineering-17-2048.jpg)