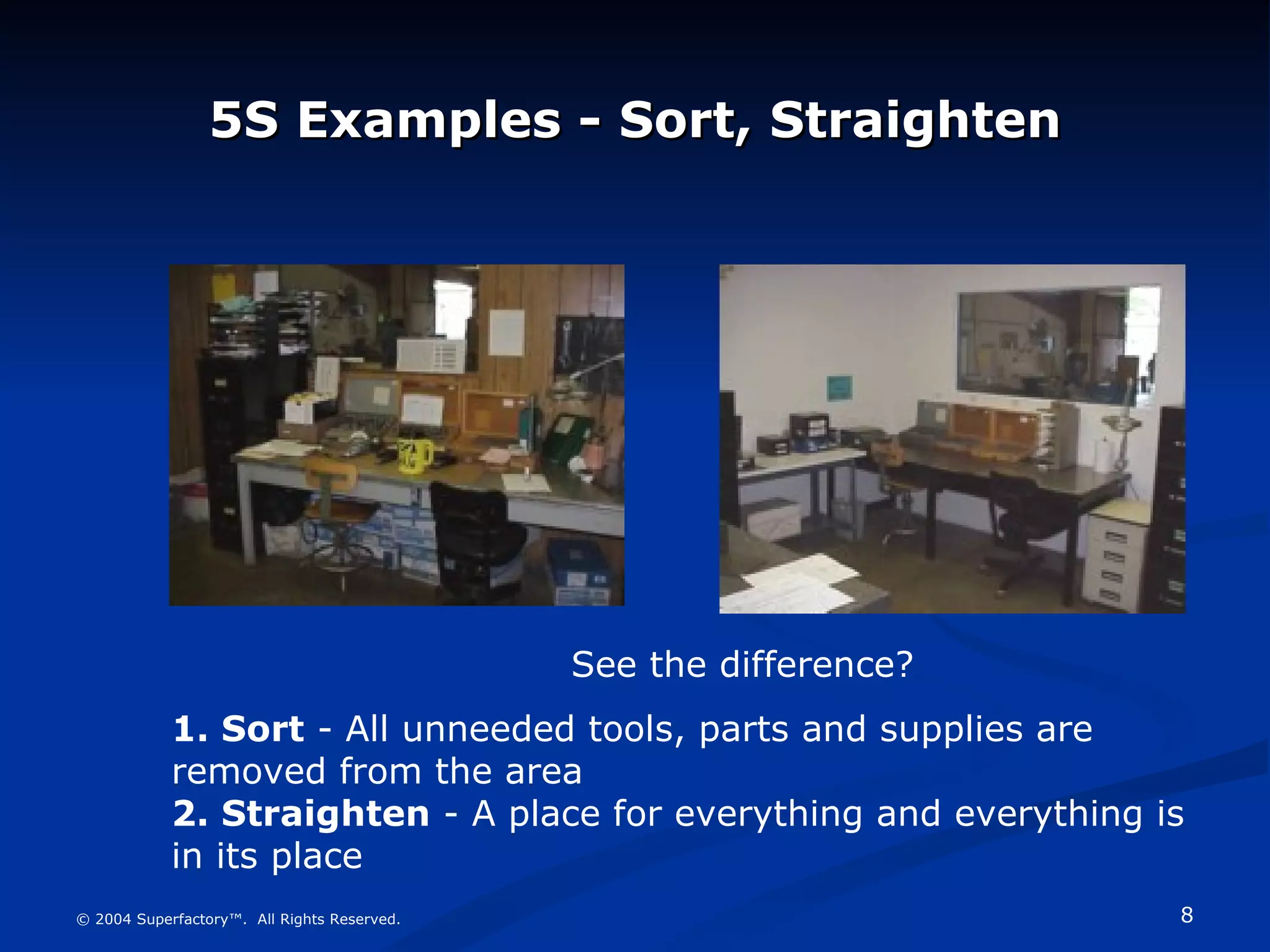

5S is a method for organizing and standardizing a workplace to improve efficiency and safety. It involves five steps: Sort, Straighten, Shine, Standardize, and Sustain. The document discusses each of the 5S steps and provides examples of how 5S implementation can reduce waste and improve visual controls in a workplace through techniques like labeling, signage, and clear organization. It emphasizes that 5S is foundational to lean manufacturing principles and creating an efficient, safe work environment.