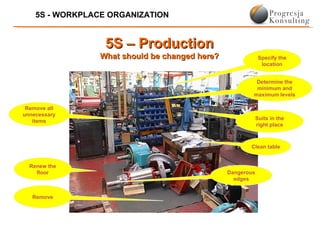

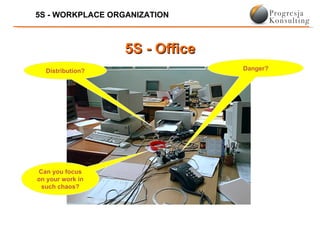

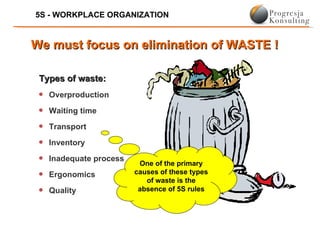

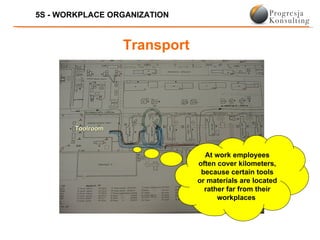

This document discusses the 5S methodology for improving workplace organization. It explains that without clear organization rules, different teams or shifts will create their own systems leading to chaos. The 5S methodology identifies five phases to improve organization: sorting, straightening, shining, standardizing, and sustaining the new system. Examples show work areas before and after applying 5S principles. The document argues that implementing 5S rules can help a company reduce waste from issues like overproduction, waiting times, transport inefficiencies, and unnecessary inventory. With better organization, employees will be more efficient and productive.