Recommended

PPT

PPT

PPT

PPT

5S training material power point slide 2.ppt

PPT

PPT

PPT

PPT

PPT

5S Workshop &Visual management - Krishna Heda

PDF

Brady 5S_HandBook - Project Sales Corp

PPTX

Introduction to 5S methodology from Japan

PPTX

PPTX

5S Basic Training, V1 By Carlos Sanchez

DOCX

PDF

PDF

PDF

PPT

PPTX

5S Rules HSE Training workers (1).pptx

PPTX

5S for Enhancing Productivity, Quality, and Safety at the Workplace

PPTX

PPTX

5s procedure_MODULE QUARTER first semes

PPTX

5 S Program Orientation Powerpoint Presentation

PPTX

PDF

Workplace management : 5S / Visual Control

PDF

5S AWARNESS TRAINING PROGRAM

PPT

5S_Training FOR MANUFACTURE INDUSTRIAL FACTORY

PPTX

1S - Sort.pptx The first stage of 5S describing how to sort within the defin...

PDF

Keppel Ltd. 2H & FY 2025 Results Presentation Slides

PDF

Certification Training Course On New Skills Across Globe

More Related Content

PPT

PPT

PPT

PPT

5S training material power point slide 2.ppt

PPT

PPT

PPT

PPT

Similar to 5S and visual factory and more detail example

PPT

5S Workshop &Visual management - Krishna Heda

PDF

Brady 5S_HandBook - Project Sales Corp

PPTX

Introduction to 5S methodology from Japan

PPTX

PPTX

5S Basic Training, V1 By Carlos Sanchez

DOCX

PDF

PDF

PDF

PPT

PPTX

5S Rules HSE Training workers (1).pptx

PPTX

5S for Enhancing Productivity, Quality, and Safety at the Workplace

PPTX

PPTX

5s procedure_MODULE QUARTER first semes

PPTX

5 S Program Orientation Powerpoint Presentation

PPTX

PDF

Workplace management : 5S / Visual Control

PDF

5S AWARNESS TRAINING PROGRAM

PPT

5S_Training FOR MANUFACTURE INDUSTRIAL FACTORY

PPTX

1S - Sort.pptx The first stage of 5S describing how to sort within the defin...

Recently uploaded

PDF

Keppel Ltd. 2H & FY 2025 Results Presentation Slides

PDF

Certification Training Course On New Skills Across Globe

PDF

MTD for Landlords – a closer look at the impact, requirements and software (H...

PDF

Prasenjit Bhaumik Plano - Proficient In JavaScript, Python, And Database Mana...

PDF

Contract_Costing_Introduction and Basics

DOCX

Best Place to Learn Old or Aged Verified Square Accounts in WWW.docx

PDF

What Is Setup for Decoration | Machine Reality Explained

PDF

Iryna Rudenko: Follow the Money: How Investment Trends Define IT Niches (UA)

DOCX

What Are Telegram Accounts and Why Are They Important for Global Communicatio...

PDF

On Demand Service Provider App Development

PDF

Top Platform to Buy Facebook Accounts in Bulk Safely.pdf

PDF

Buy Verified PayPal Accounts for Safe, Hassle-Free Transactions.pdf

PDF

Rami Tawasha - Specializes In High-Impact Work

PPTX

Retail Location and Site Selection .pptx

PDF

Preparing-Iced-Petit-Fours-PPTpresent.pdf

PDF

A Brief Introduction About Xin Yi Hoo

PPTX

5, Money Number Tax and Wages 19072017.pptx

PDF

KGA - Governing administration in a consolidated market

PDF

𝐖𝐚𝐠 𝐂𝐥𝐨𝐧𝐞 𝐏𝐞𝐭 𝐂𝐚𝐫𝐞 𝐀𝐩𝐩 𝐃𝐞𝐯𝐞𝐥𝐨𝐩𝐦𝐞𝐧𝐭

PDF

Ultra Map Section II Multifaceted Second Edition.pdf

5S and visual factory and more detail example 1. 5S and Visual Factory

5S and Visual Factory

Superfactory Manufacturing Excellence Series

Lean Overview

5S & Visual Factory

Cellular Manufacturing

Jidoka

Kaizen

Poka Yoke & Mistake Proofing

Quick Changeover & SMED

Production Preparation Process (3P)

Pull Manufacturing & Just In Time

Standard Work

Theory of Constraints

Total Productive Maintenance

Training Within Industry (TWI)

Value Streams

2. © 2007 Superfactory™. All Rights Reserved. 2

Contents

Contents

• Introduction

• Background and History

• Components and Implementation

• Knowledge Check

3. © 2007 Superfactory™. All Rights Reserved. 3

Introduction

Introduction

• 5S is a method to improve and sustain workplace

organization

• 5S represents 5 disciplines for maintaining a visual

workplace (visual controls and information systems).

• These are foundational to continual improvement and a

manufacturing strategy based on "Lean Manufacturing"

(waste removing) concepts.

• Reduces clutter

• Reduces the time it takes to look for tools and

equipment

• “A place for everything and everything in its place”

• Improves how the operation appears to customers –

always be “tour ready”

• Creates pride in the workplace

• Many companies have a standard that any tool

must be able to be found within 60 seconds.

4. © 2007 Superfactory™. All Rights Reserved. 4

Components and Implementation

Components and Implementation

• 5S and Lean Manufacturing

• Elements of 5S

– Sort

– Straighten

– Shine

– Standardize

– Sustain

– Safety

• Visual Factory

• Implementation plan

5. © 2007 Superfactory™. All Rights Reserved. 5

Elements of 5S

Elements of 5S

• Sort

– Remove all unnecessary materials and equipment

• Straighten

– Make it obvious where things belong

• Shine

– Clean everything, inside and out

• Standardize

– Establish policies and procedures to ensure 5S

• Sustain

– Training, daily activities

• Safety (often called “6S” or “5S + 1”)

– A safety commitment in all activities

6. © 2007 Superfactory™. All Rights Reserved. 6

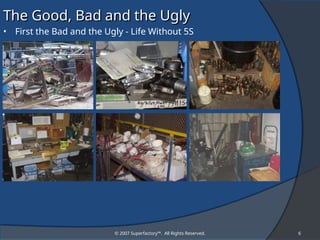

The Good, Bad and the Ugly

The Good, Bad and the Ugly

• First the Bad and the Ugly - Life Without 5S

7. © 2007 Superfactory™. All Rights Reserved. 7

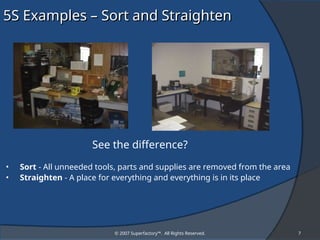

5S Examples – Sort and Straighten

5S Examples – Sort and Straighten

See the difference?

• Sort - All unneeded tools, parts and supplies are removed from the area

• Straighten - A place for everything and everything is in its place

8. © 2007 Superfactory™. All Rights Reserved. 8

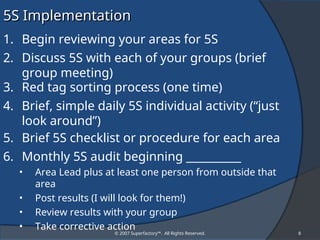

5S Implementation

5S Implementation

1. Begin reviewing your areas for 5S

2. Discuss 5S with each of your groups (brief

group meeting)

3. Red tag sorting process (one time)

4. Brief, simple daily 5S individual activity (“just

look around”)

5. Brief 5S checklist or procedure for each area

6. Monthly 5S audit beginning __________

• Area Lead plus at least one person from outside that

area

• Post results (I will look for them!)

• Review results with your group

• Take corrective action

9. © 2007 Superfactory™. All Rights Reserved. 9

Red Tag Process

Red Tag Process

• One-time activity to remove or disposition

clutter

• To be started within two weeks of this training

1. Identify clutter, unused equipment, etc

2. Fill out and attach red tag

3. Note in red tag log

4. Red tags must be dispositioned within 30 days