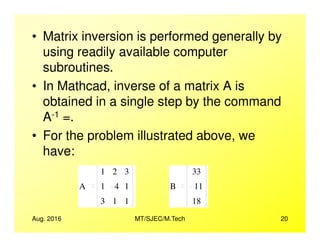

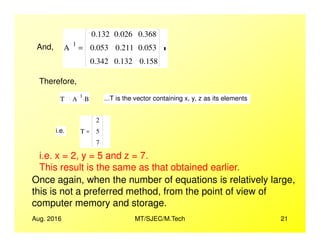

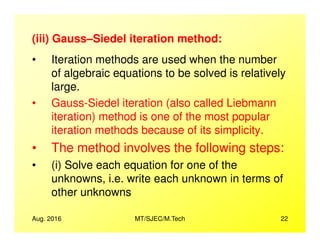

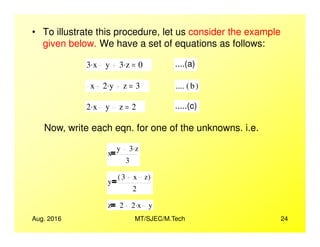

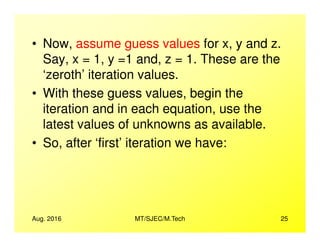

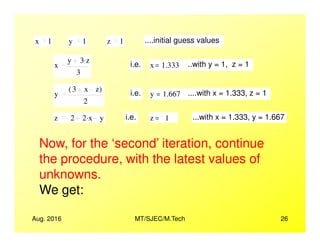

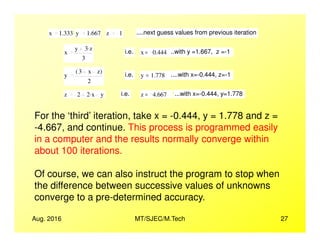

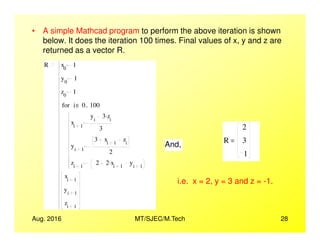

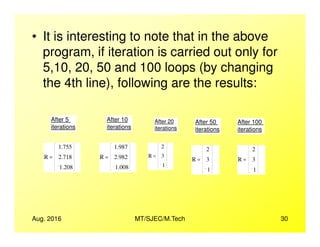

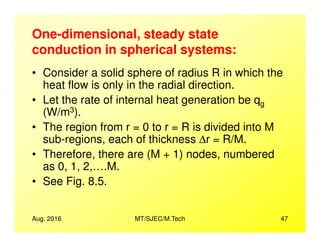

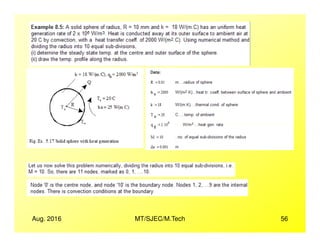

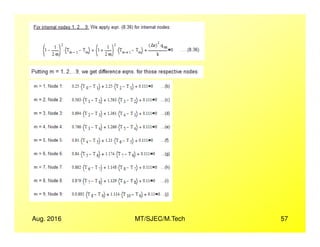

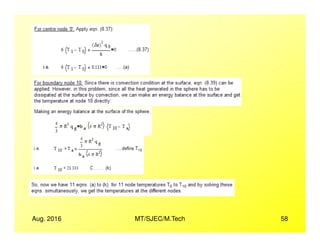

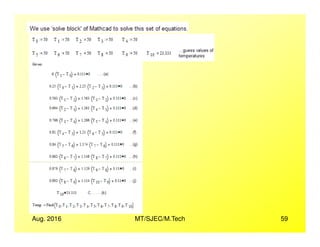

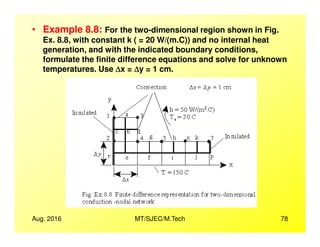

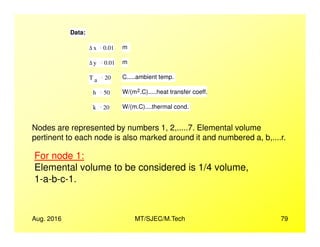

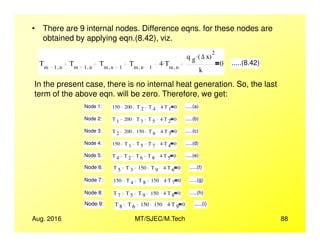

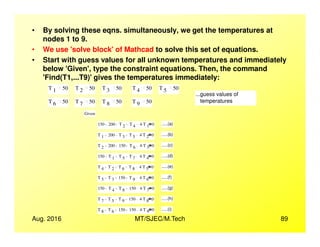

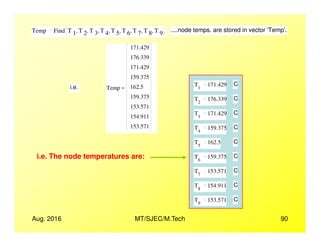

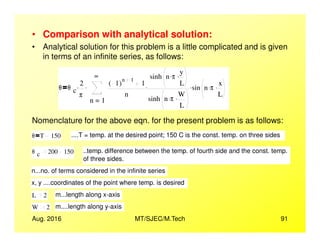

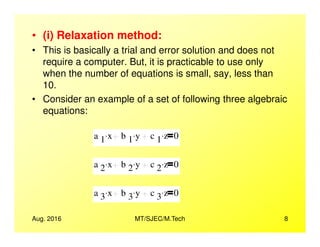

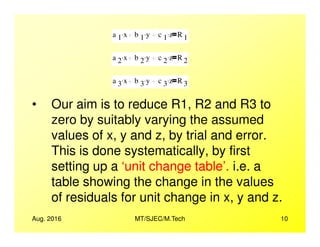

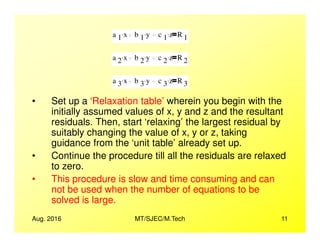

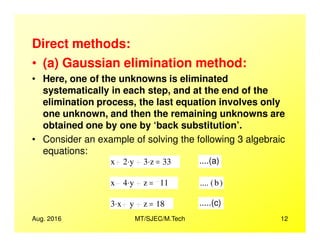

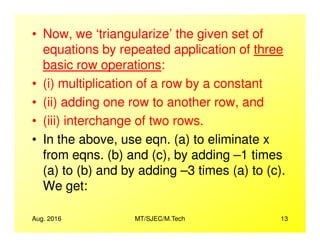

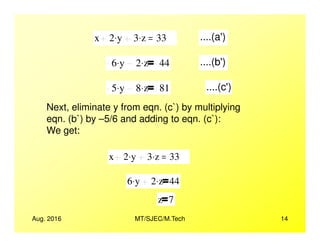

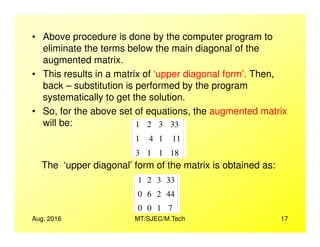

This document discusses numerical methods for solving steady-state 1D and 2D heat conduction problems. It describes the relaxation method, Gaussian elimination method, and Gauss-Siedel iteration method for solving systems of simultaneous algebraic equations arising in heat conduction analyses. The Gaussian elimination and matrix inversion methods use matrix operations to systematically eliminate variables. The Gauss-Siedel iteration method iteratively solves for each variable using the most recently calculated values of other variables until convergence is reached. Examples are provided to illustrate each numerical solution technique.

![• (b) Matrix inversion method:

• In this method, the set of equations is written in

the following matrix form:

[A] [T] = [B], where

[A] is the coefficient matrix, [T] is the vector of

temperatures to be found out, and [B] is the

vector of constants (RHS) of the equations.

Aug. 2016 MT/SJEC/M.Tech 19

• Solution of this system by matrix inversion

method is given by:

[T] = [A]-1 [B], where [A]-1 is the inverse of

matrix [A].](https://image.slidesharecdn.com/numericalmethods-steady-state-1dand2d-part-ii-160906120506/85/NUMERICAL-METHODS-IN-STEADY-STATE-1D-and-2D-HEAT-CONDUCTION-Part-II-19-320.jpg)