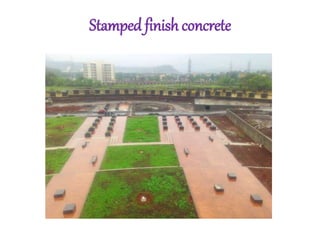

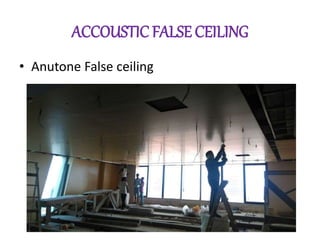

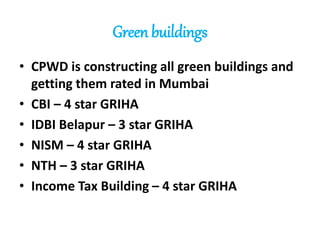

The document discusses new materials and technologies used by CPWD in Mumbai, including post-tensioned slabs, autoclaved aerated concrete blocks, glass fiber reinforced concrete panels, stamped finish concrete, geofoam flooring, acoustic false ceilings, double stack car parking, solar panels, and energy efficient designs. Post-tensioned slabs provide material savings and reduced dead load. Projects using these include the CBI office building and buildings under construction at the Income Tax office and IDBI.