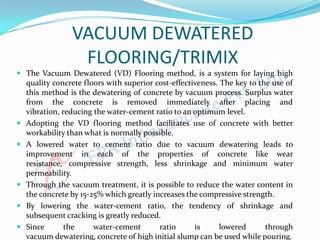

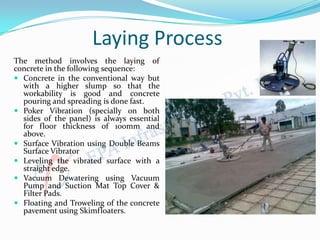

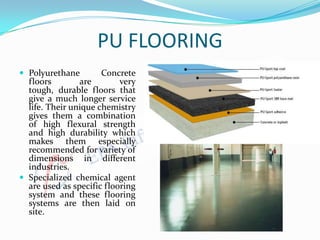

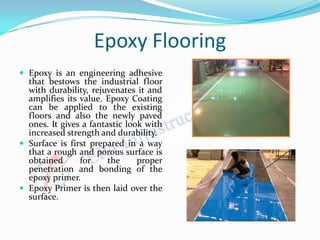

EPA Infrastructure Pvt. Limited provides various types of industrial flooring systems suitable for different applications. The document discusses vacuum dewatered flooring/trimix, PU flooring, PE foam flooring, and epoxy flooring. Vacuum dewatered flooring involves removing excess water from concrete through vacuuming, resulting in stronger, more durable floors. PU and epoxy flooring provide scratch and impact resistance along with long lifespan. PE foam flooring is lightweight and absorbs sound and impact vibrations while being moisture and mold resistant. All of these flooring types deliver strength, durability, and maintenance benefits for industrial settings.