The document discusses precast concrete construction. Some key points:

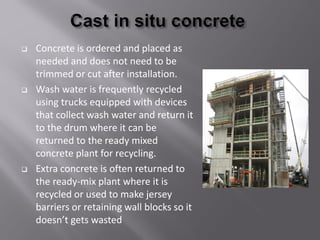

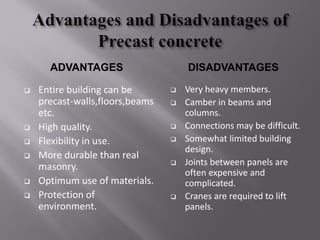

- Precast concrete components are cast off-site in a controlled environment and transported to the construction site for assembly. This allows for standardized, mass produced elements.

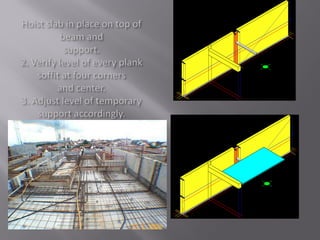

- Large precast concrete panels form the walls and floors, connecting vertically and horizontally. When joined, they form a rigid box structure that transfers lateral loads.

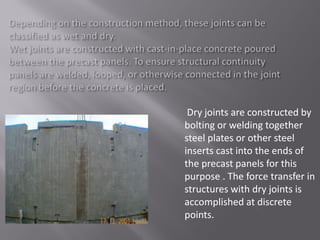

- Connections between precast elements can be either dry joints using bolts/welds, or monolithic placement with concrete poured to join components.