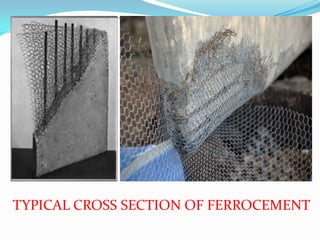

Ferrocement is a thin reinforced concrete made of wire mesh and cement mortar. It was introduced in 1943 and offers high strength and flexibility compared to conventional concrete. Ferrocement consists of thin layers of wire mesh embedded in and covered by a sand-cement mortar mix, with a typical ratio of 5% wire mesh to 95% mortar. It can be formed into various shapes by hand or machine and has applications in construction, agriculture, transportation and more due to its strength, versatility and affordability.