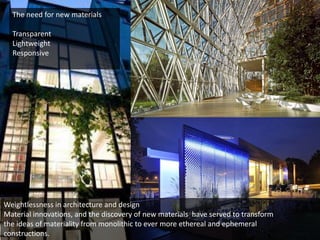

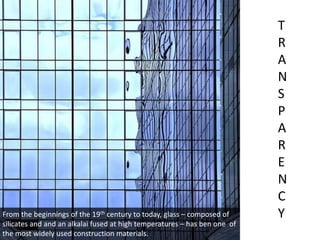

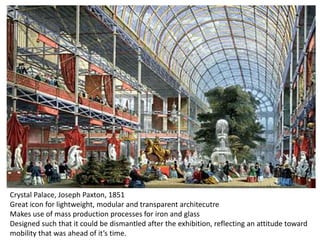

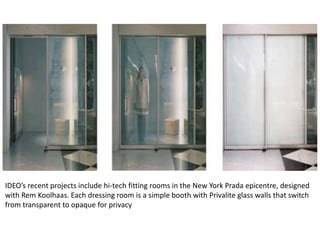

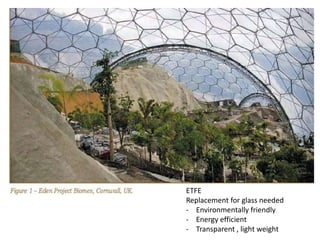

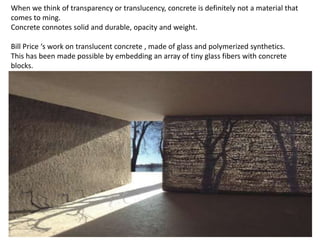

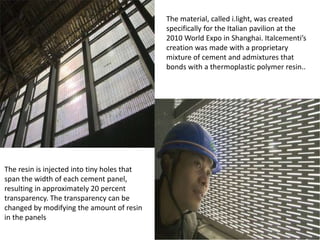

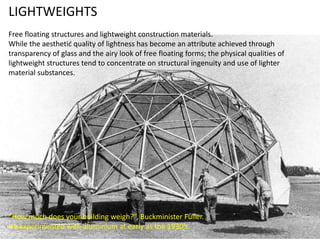

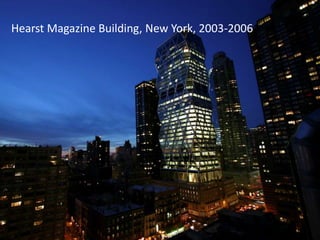

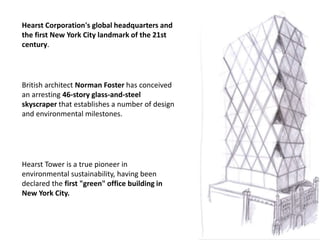

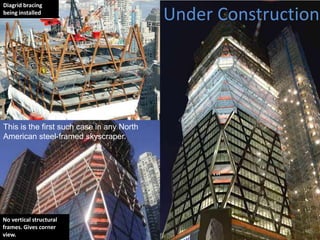

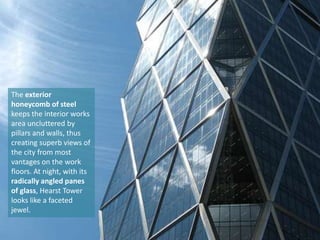

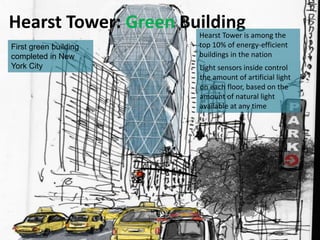

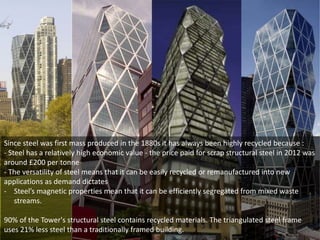

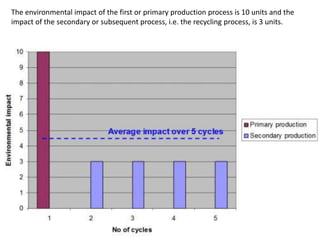

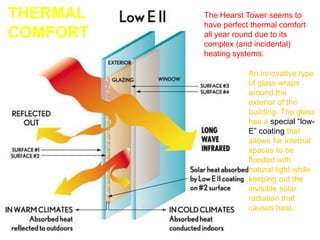

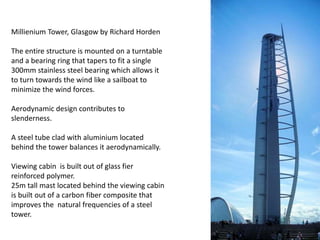

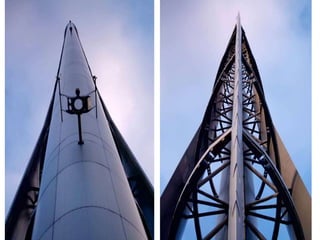

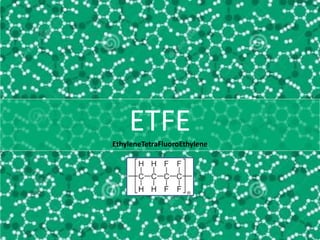

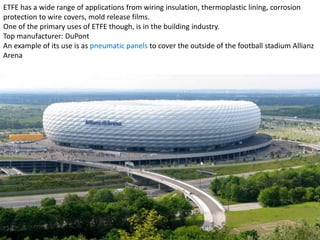

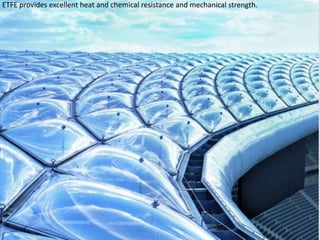

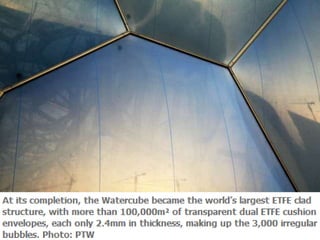

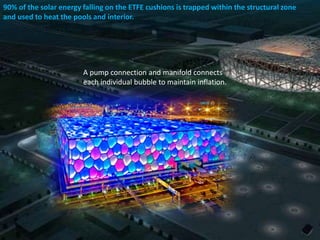

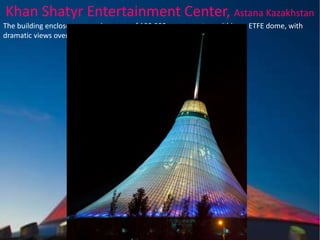

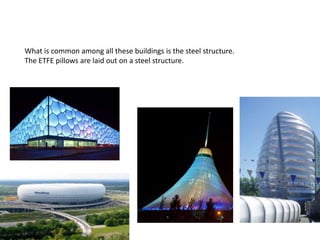

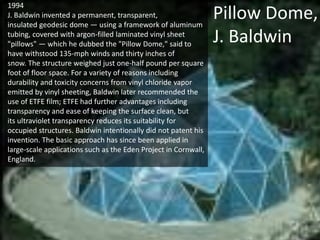

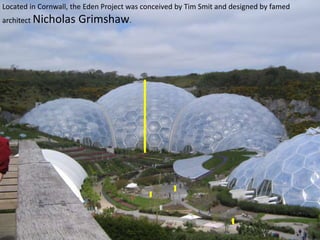

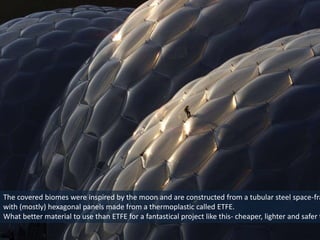

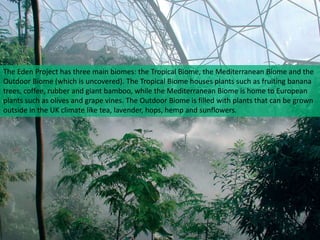

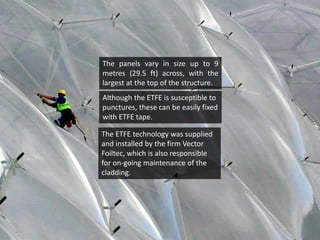

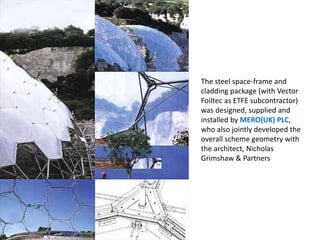

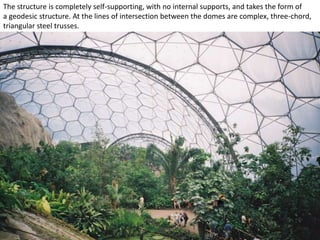

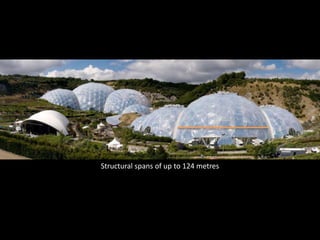

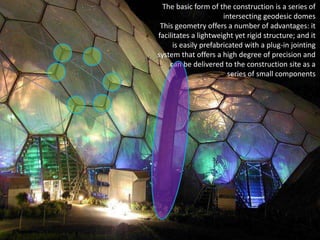

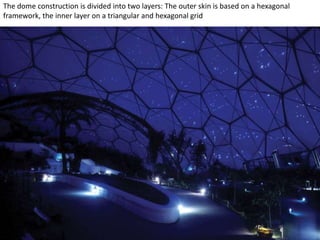

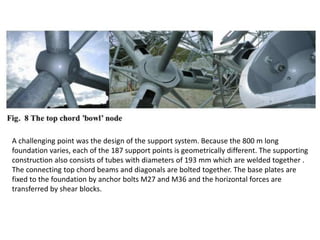

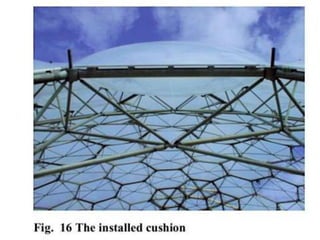

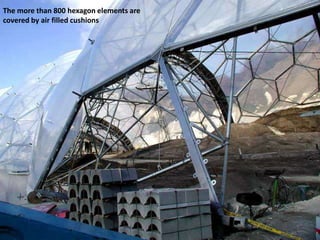

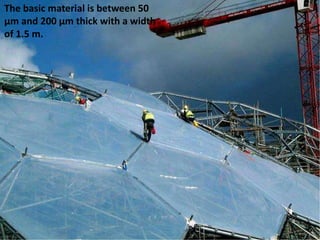

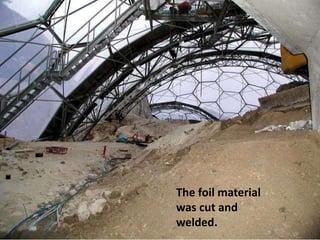

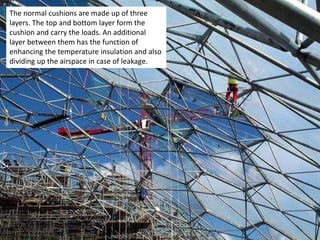

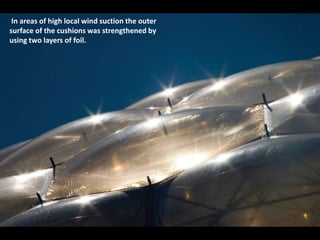

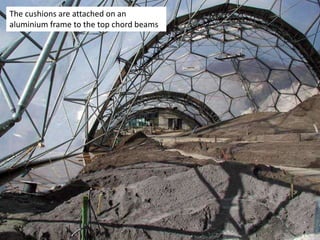

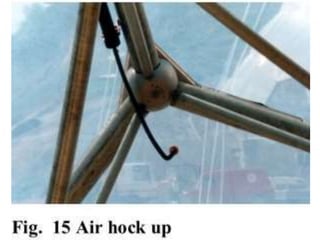

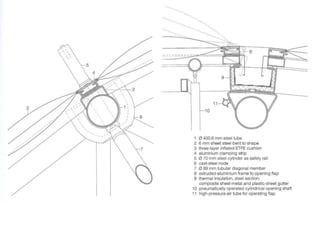

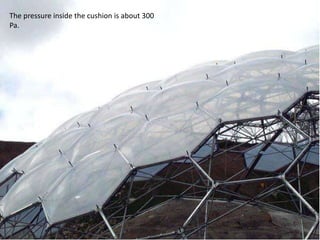

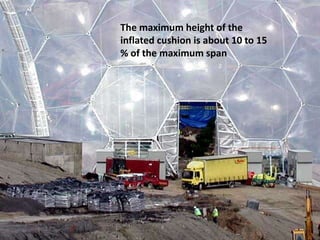

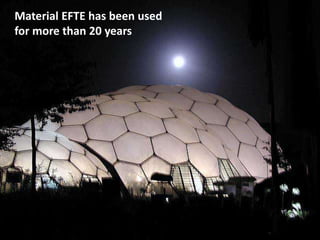

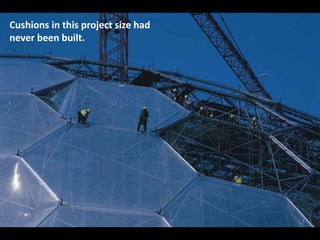

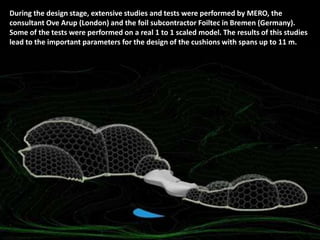

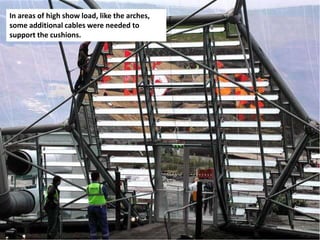

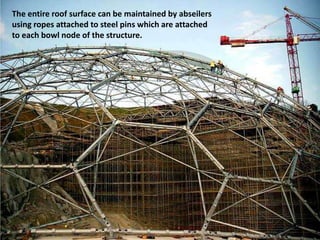

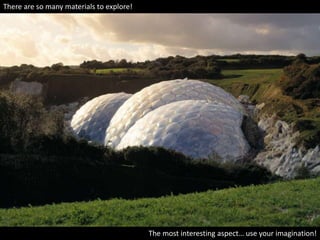

The document discusses advanced building materials and their transformation in architecture, highlighting the evolution from traditional materials to innovative, lightweight options like various types of glass and ETFE. It emphasizes the importance of transparency, environmental sustainability, and structural ingenuity in modern designs, with examples such as the Hearst Tower and the Eden Project. Additionally, it explores the development of materials like translucent concrete and the applications of ETFE in iconic structures, showcasing the blending of form and function in contemporary architecture.