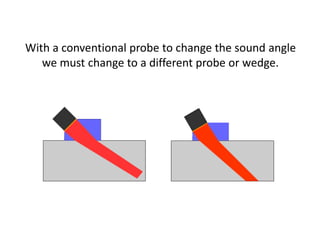

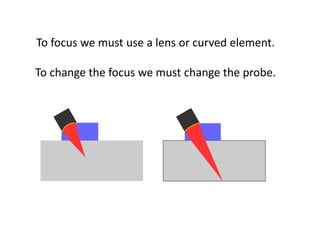

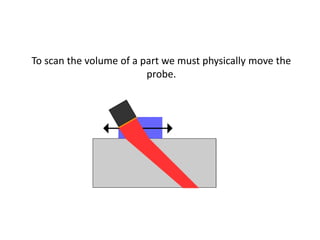

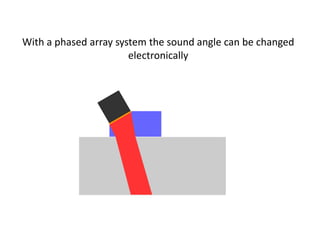

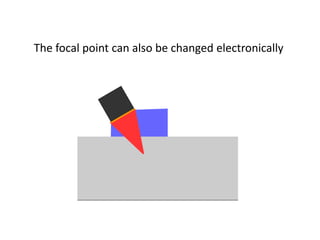

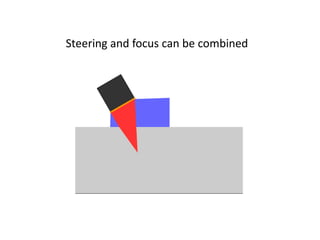

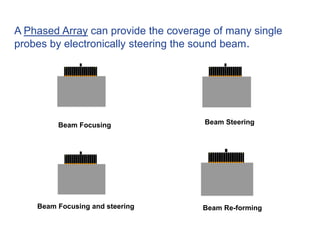

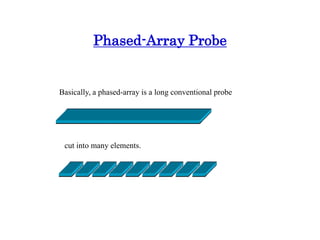

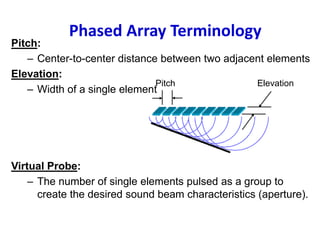

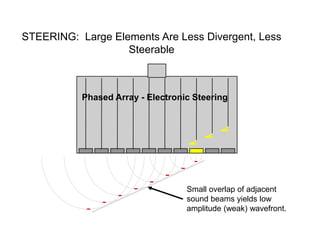

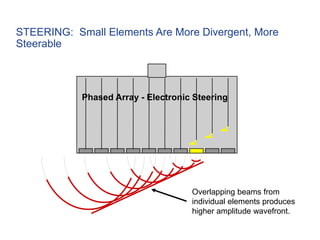

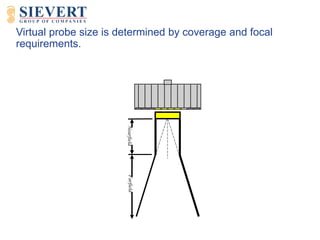

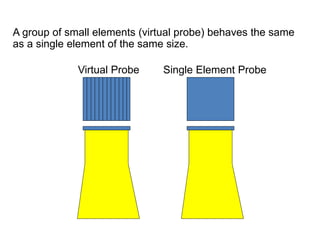

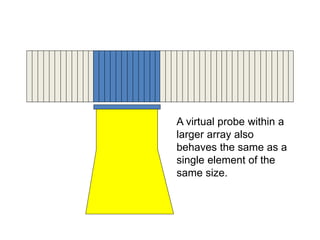

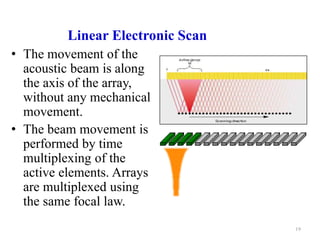

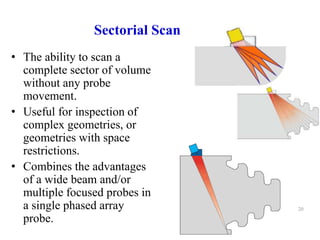

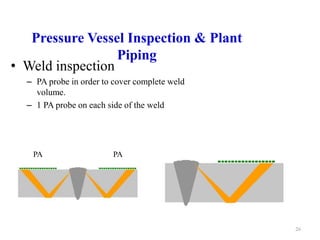

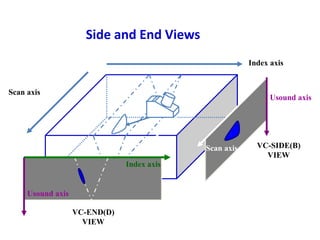

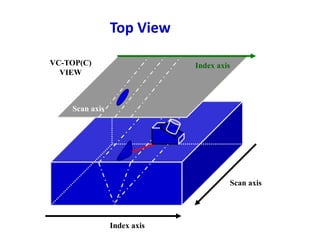

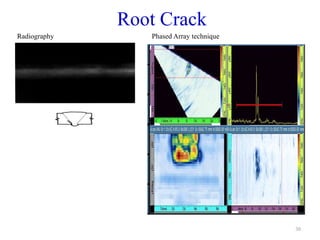

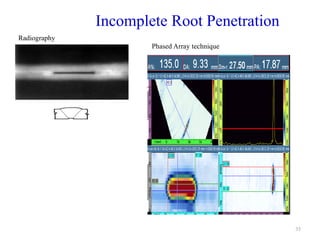

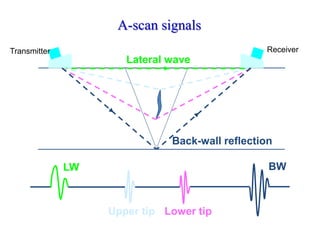

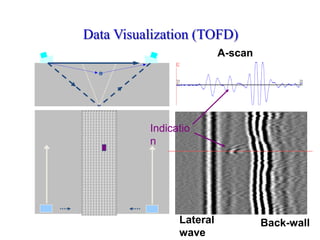

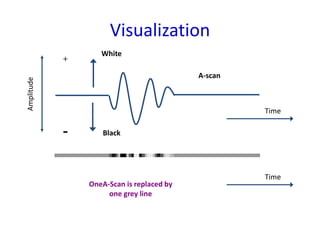

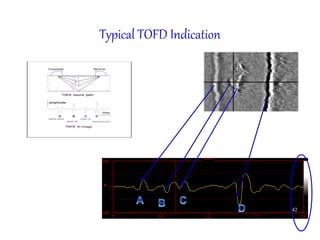

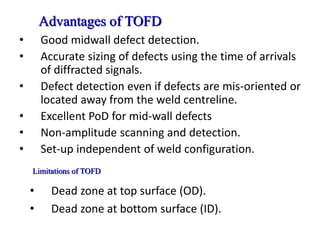

Phased array and TOFD UT techniques allow for electronic control of ultrasound beam characteristics like angle, focus, and scanning. With phased arrays, these beam modifications can be performed electronically by introducing time shifts to individual transducer elements. This enables functions like electronic steering and focusing without mechanical probe changes. TOFD uses diffraction of ultrasound from defect edges to visualize and size internal flaws. Both techniques provide benefits over conventional UT like inspection speed and flexibility, improved detection of defects, and the ability to inspect complex or restricted geometries. They find application in industries like aerospace, energy, and manufacturing for non-destructive testing of welds and structures.