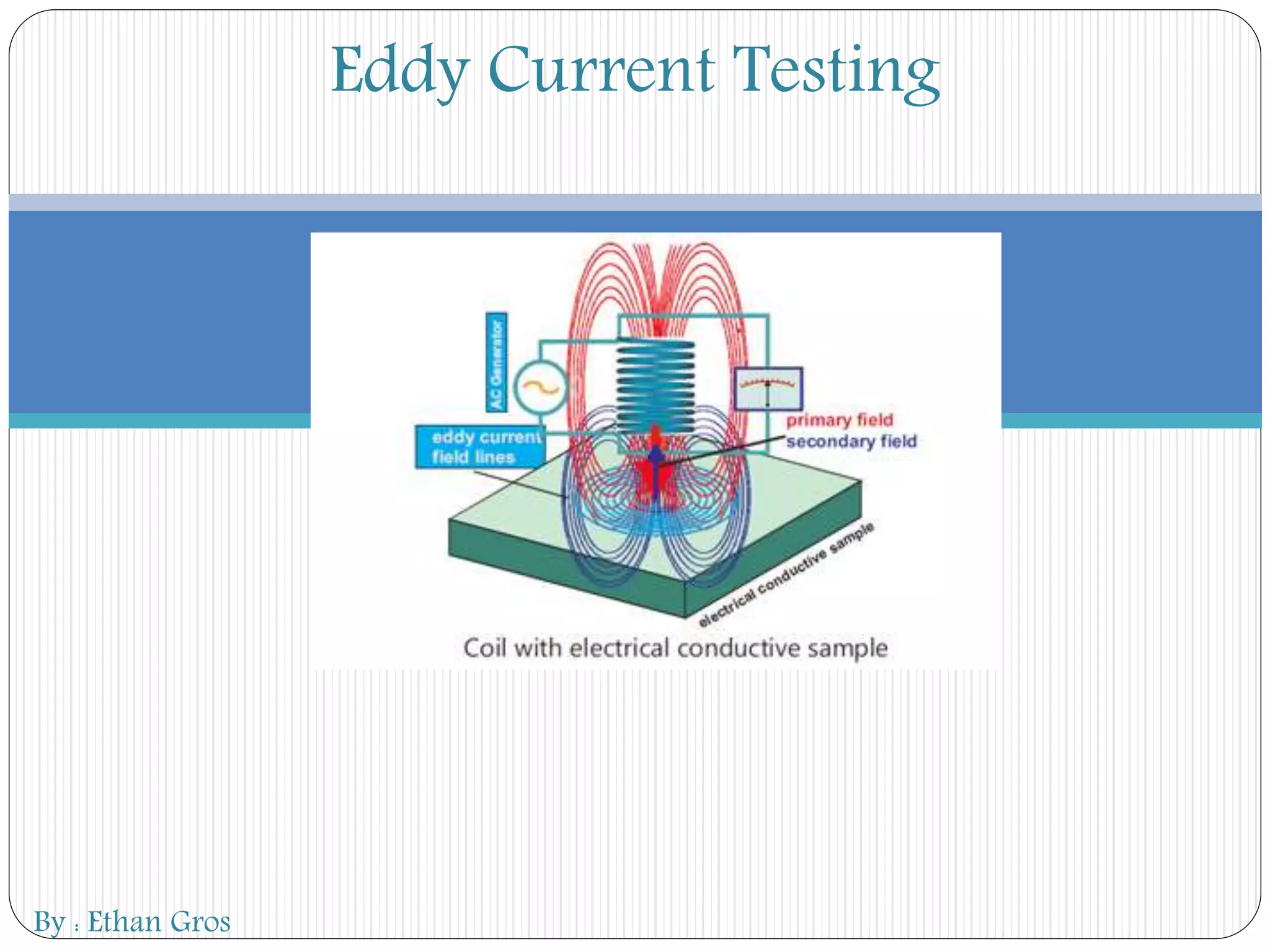

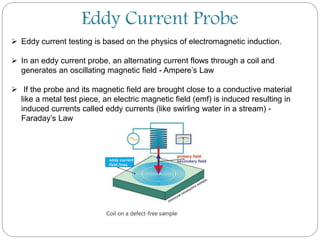

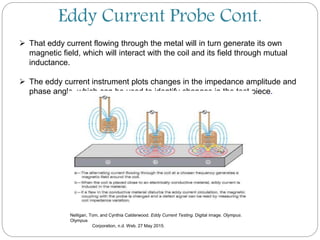

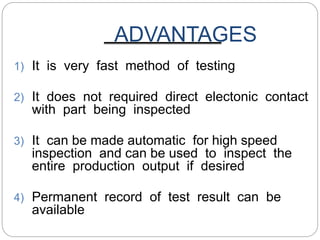

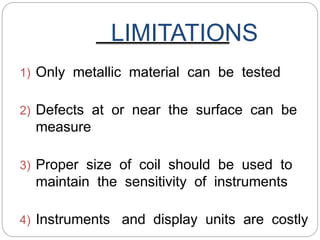

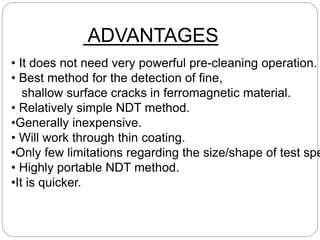

Eddy current testing uses electromagnetic induction to detect surface and near-surface flaws in conductive materials like metals. An alternating current in a probe coil generates a magnetic field that induces eddy currents when brought near a test piece. Changes in the eddy currents from flaws are detected as changes in impedance amplitude and phase angle. While fast and not requiring contact, eddy current testing works only on metals and detects only surface and near-surface defects. It also requires specialized, costly instruments. Magnetic particle testing magnetizes materials to draw magnetic particles to surface flaws and is capable of finding shallow flaws, making it a relatively simple and inexpensive method well-suited to ferromagnetic metals.