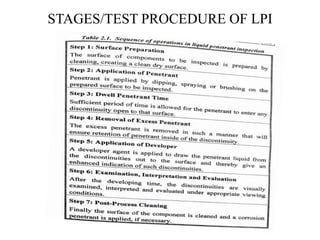

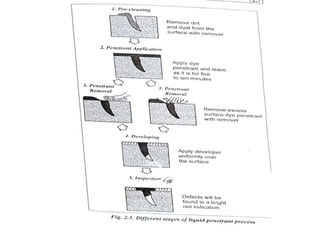

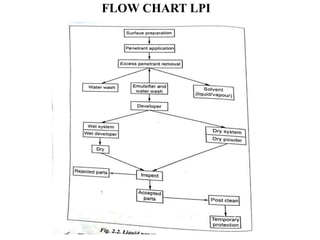

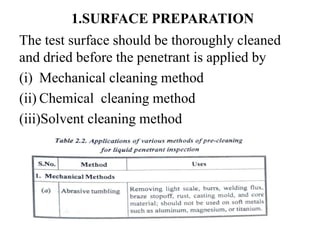

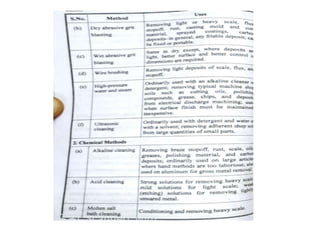

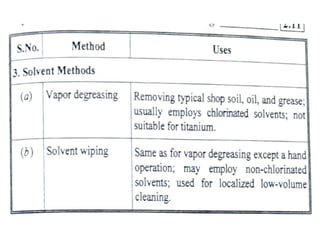

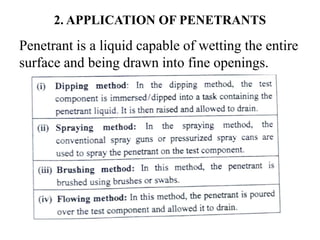

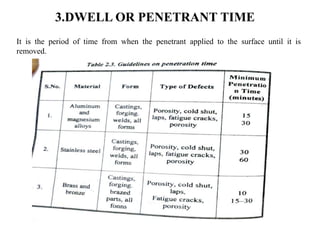

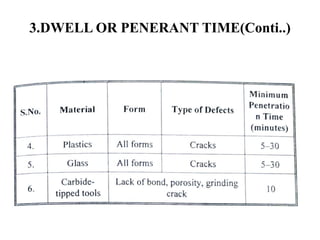

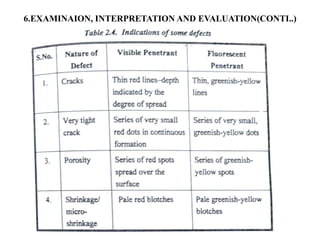

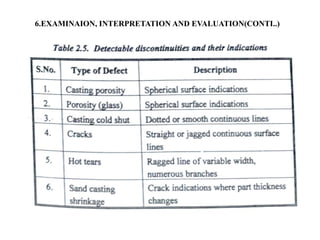

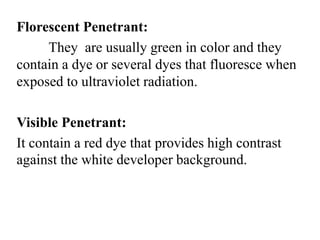

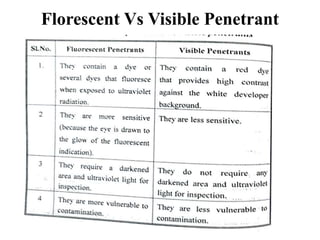

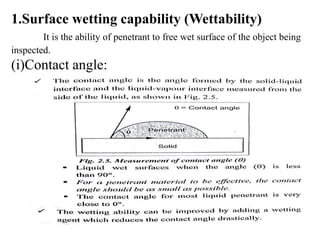

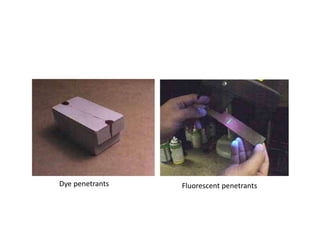

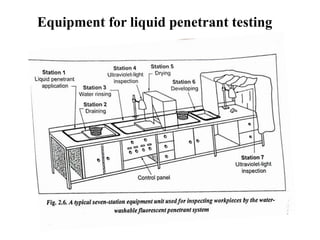

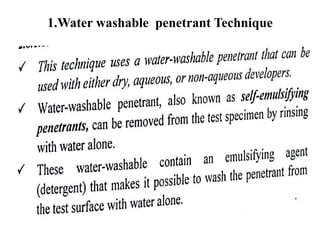

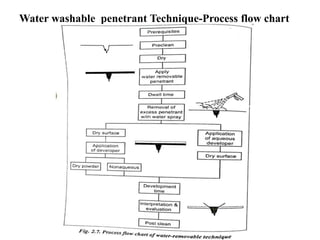

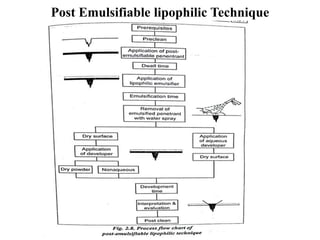

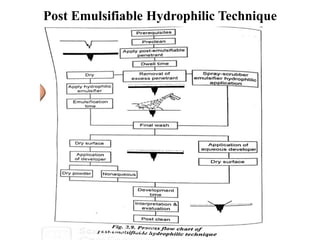

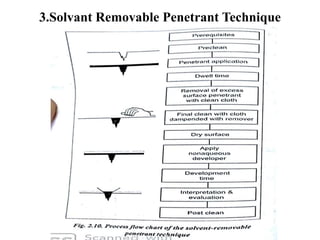

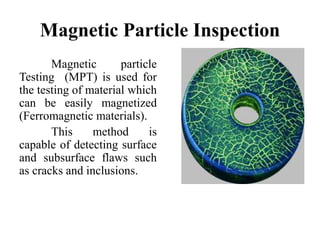

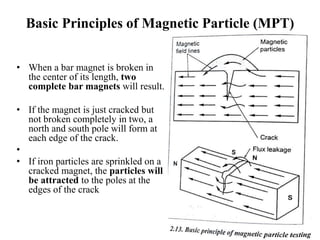

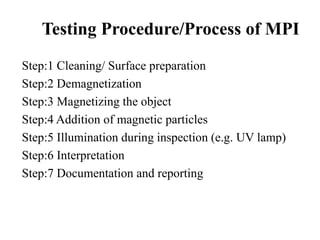

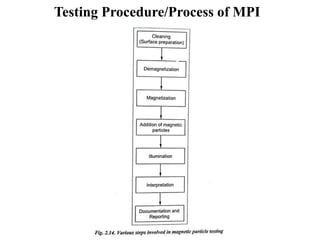

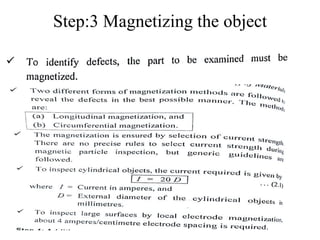

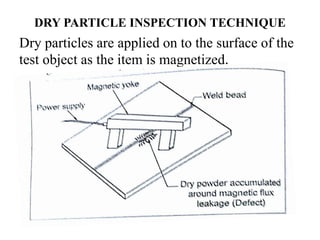

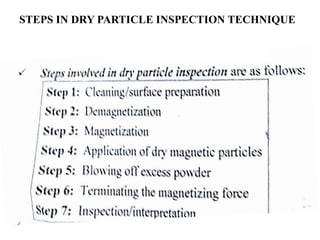

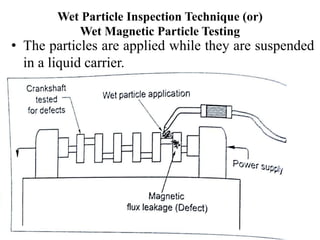

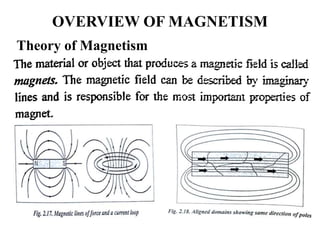

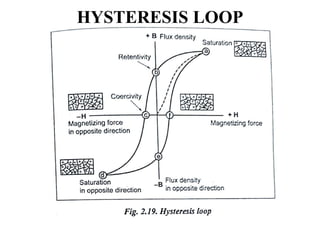

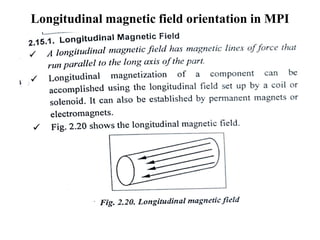

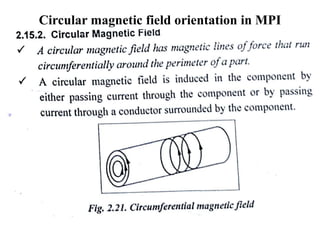

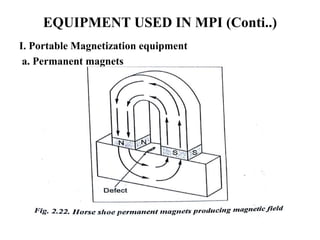

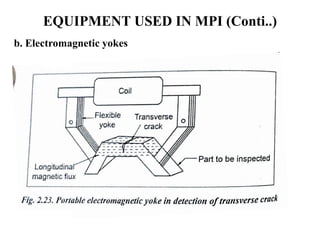

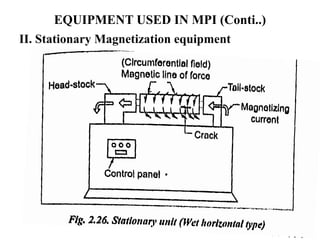

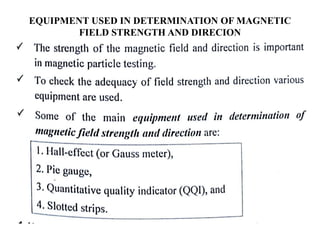

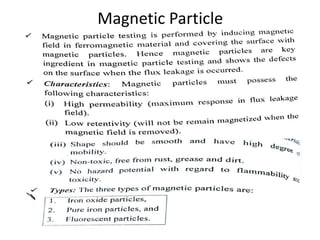

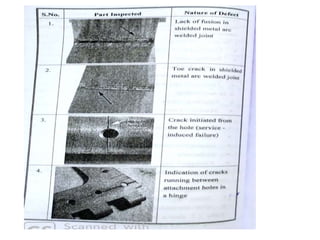

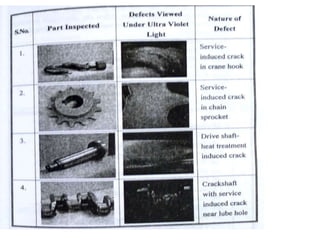

The document discusses two non-destructive testing methods: liquid penetrant testing and magnetic particle testing. Liquid penetrant testing uses liquid that is drawn into surface cracks by capillarity, then a developer reveals the flaws. The process involves surface cleaning, penetrant application, dwell time, developer application and inspection. Magnetic particle testing uses magnetism to detect subsurface flaws in ferromagnetic materials. Iron particles are attracted to cracks when the part is magnetized. The process involves demagnetization, magnetization, particle application and inspection under lighting. Both are widely used to inspect parts for cracks and defects.