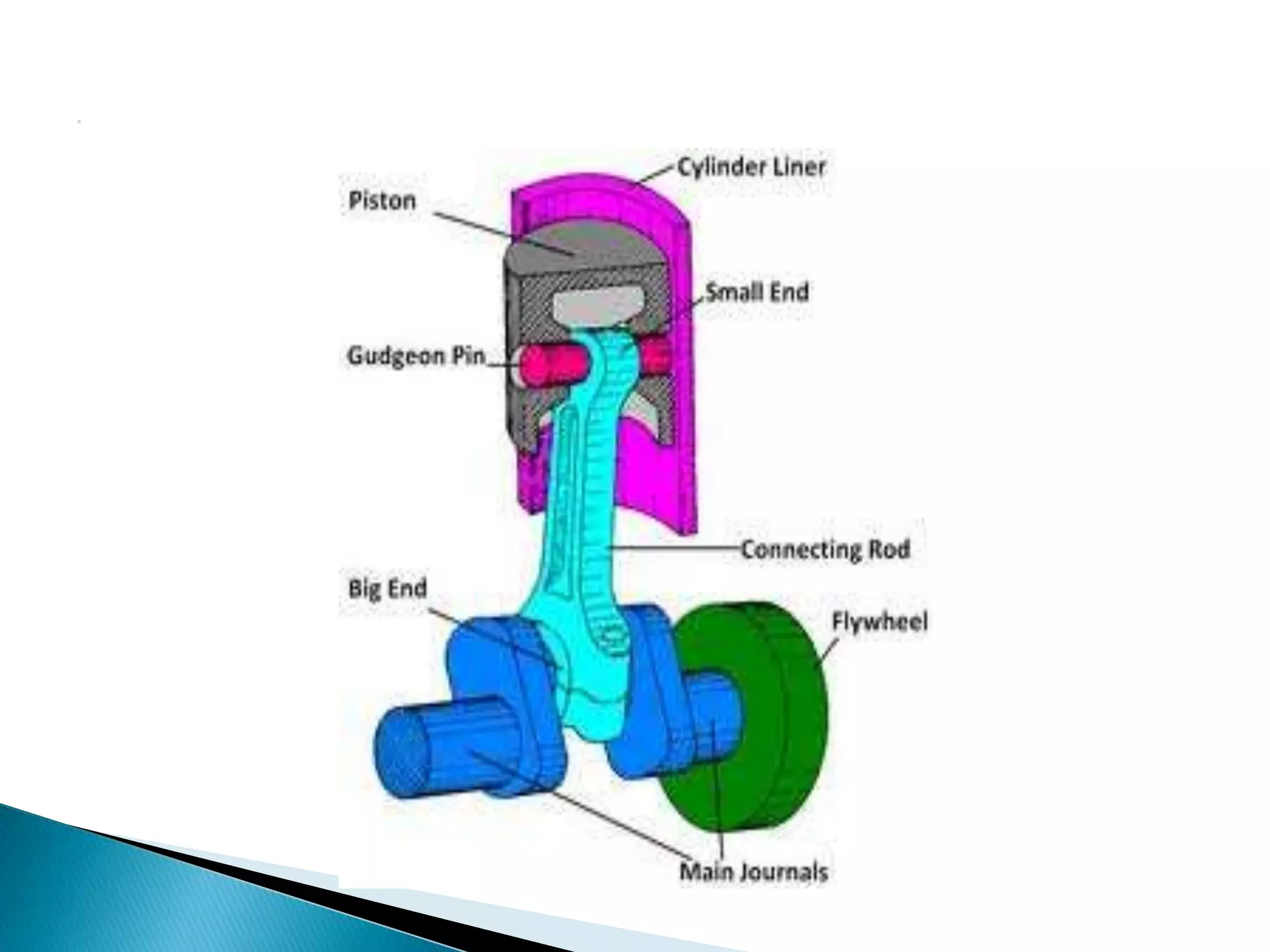

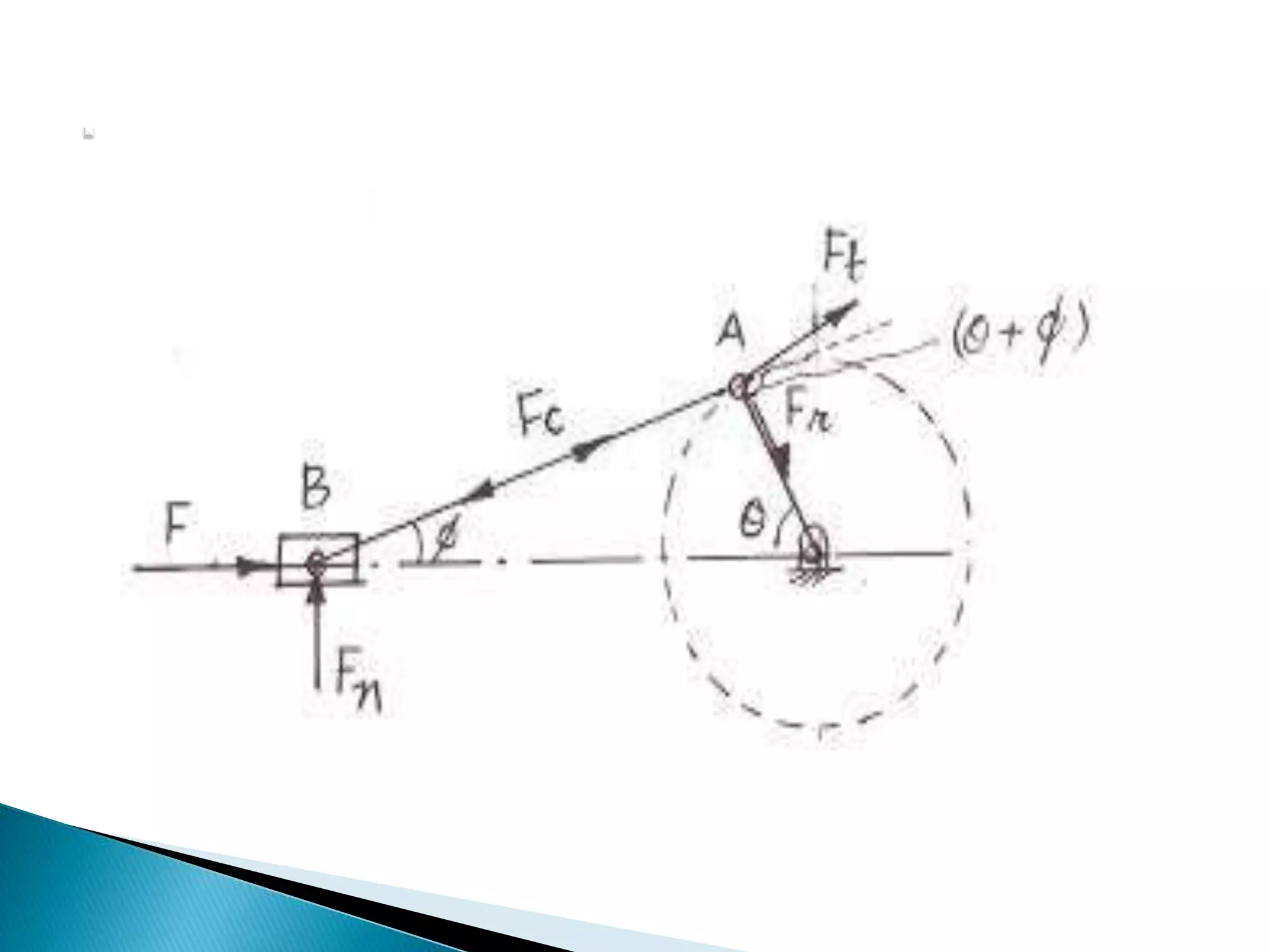

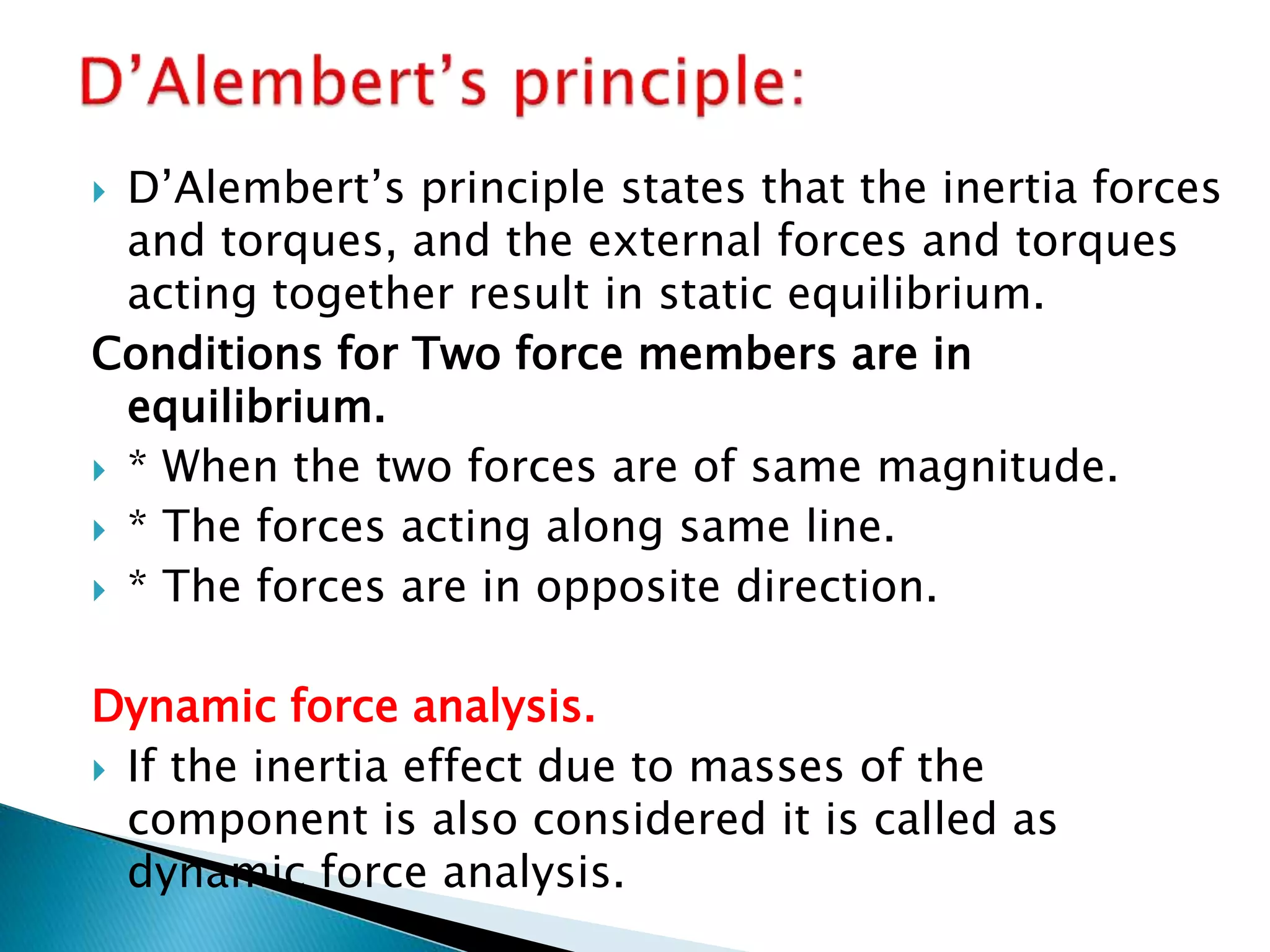

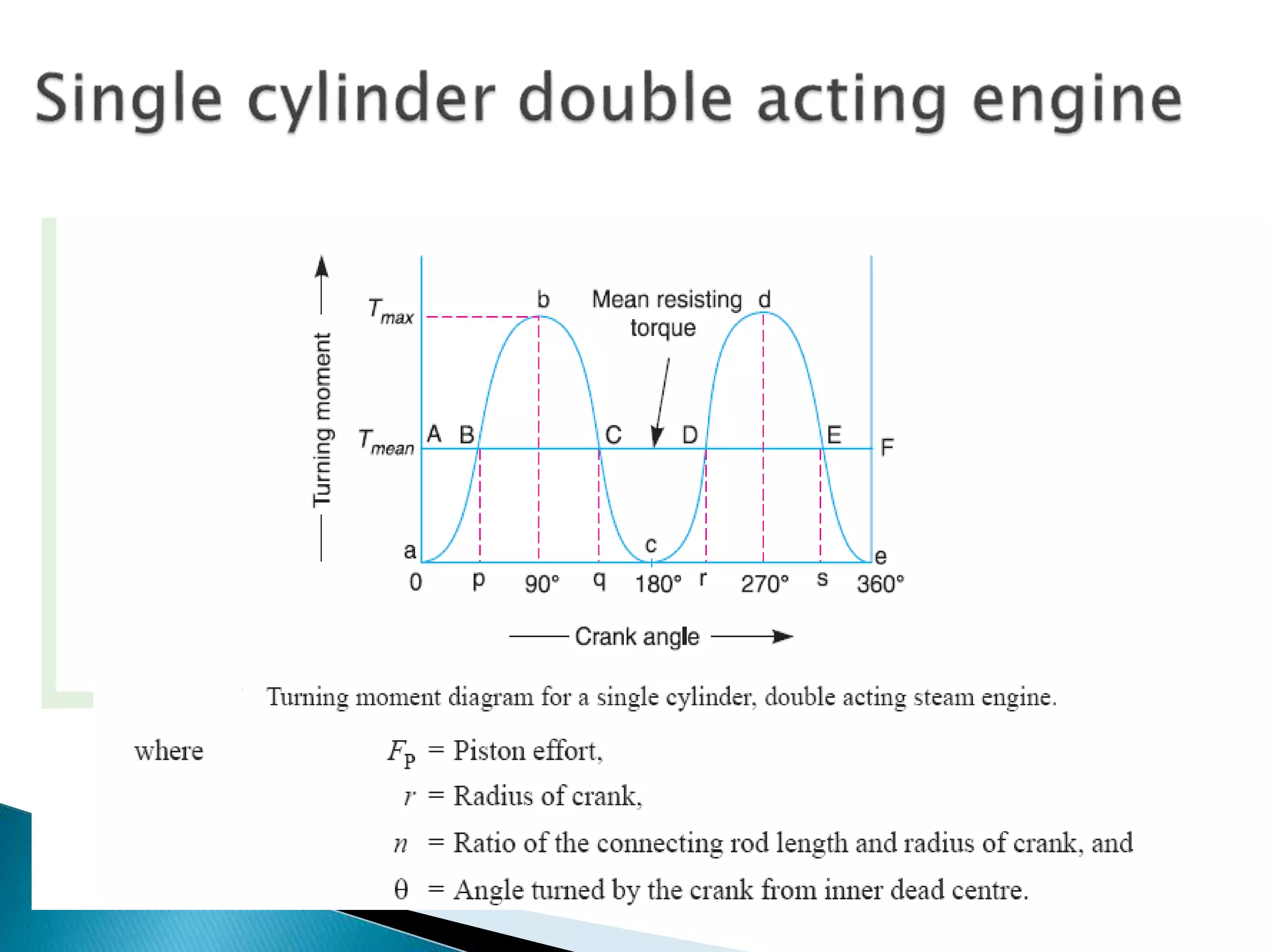

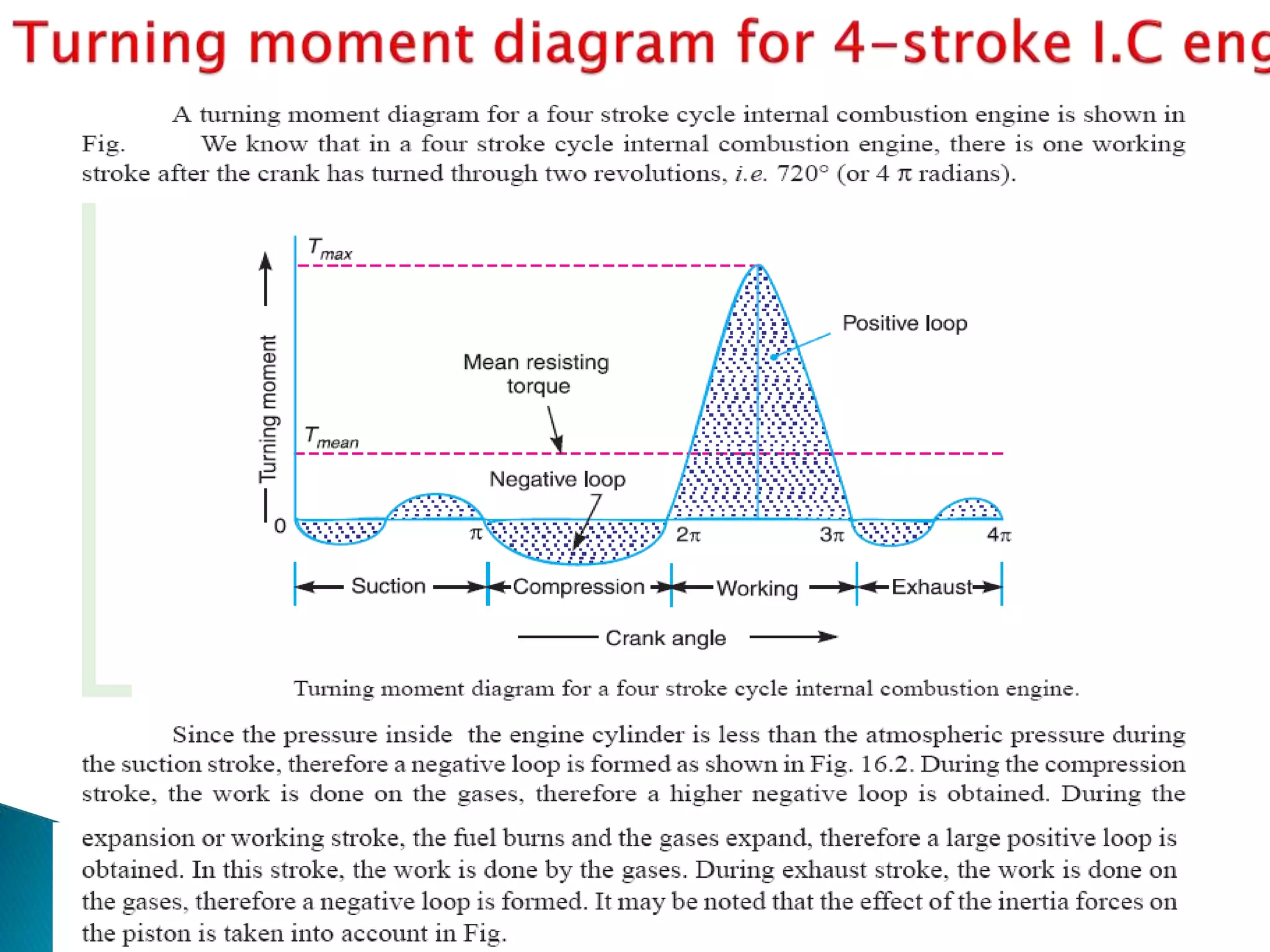

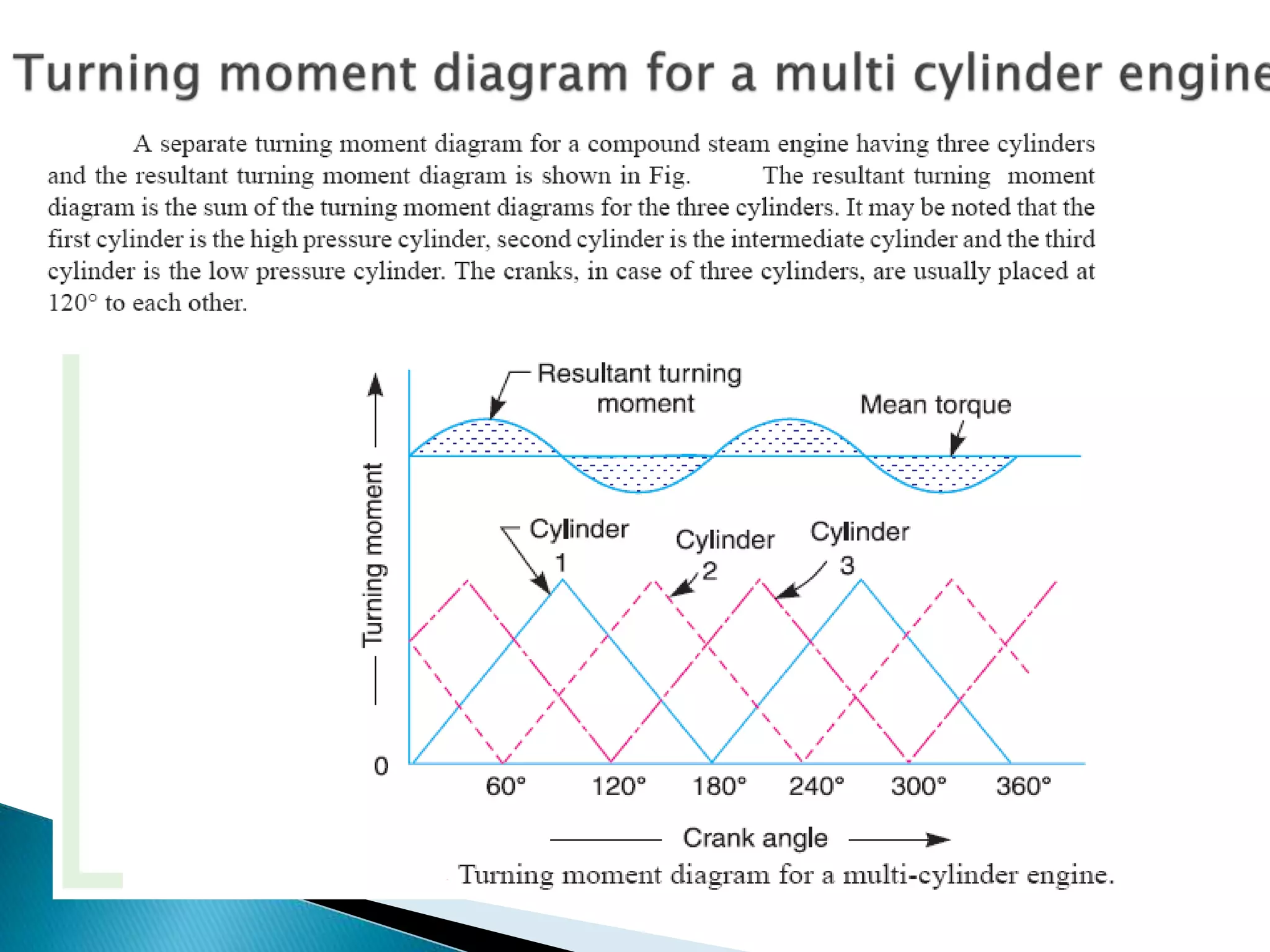

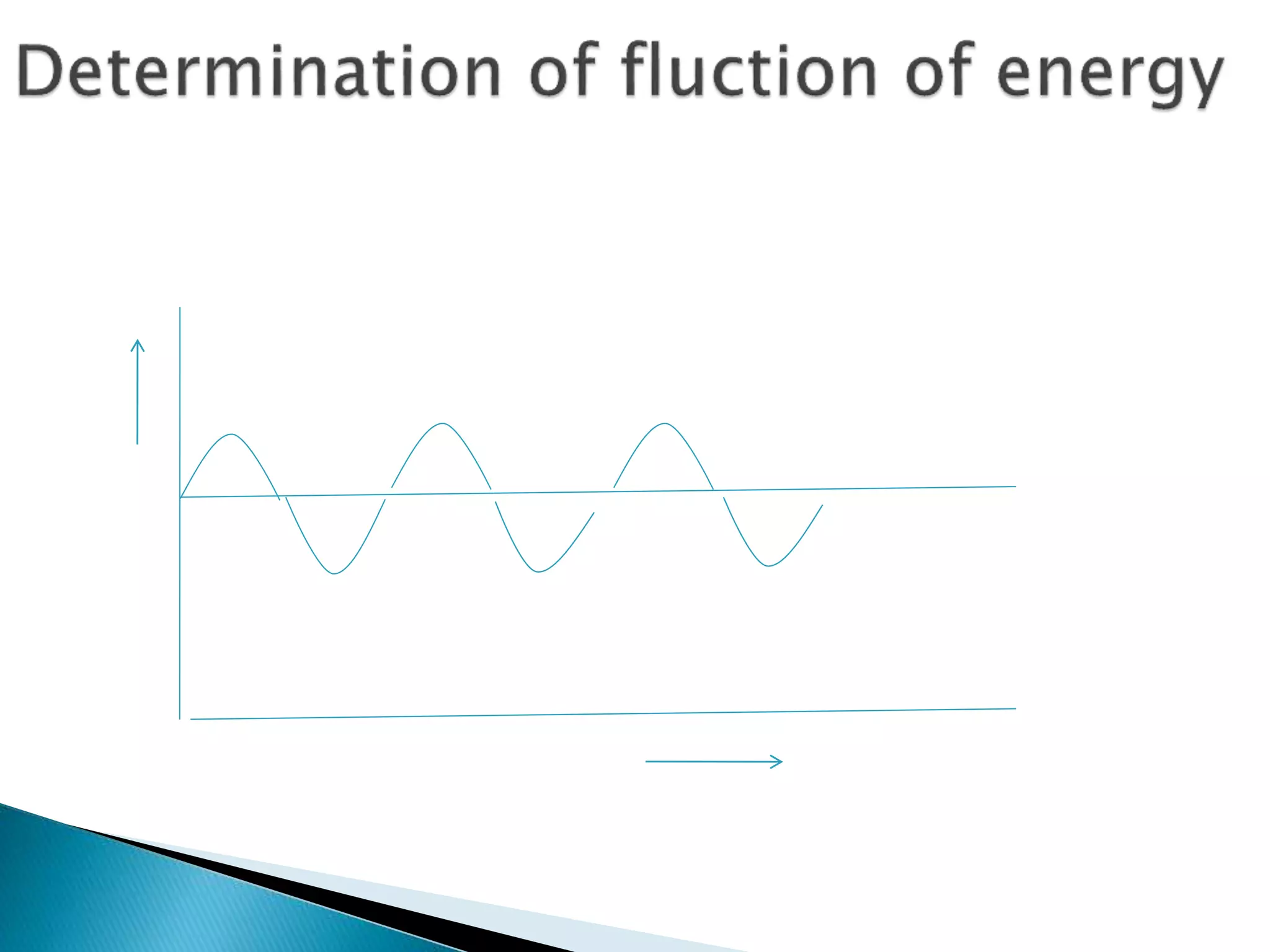

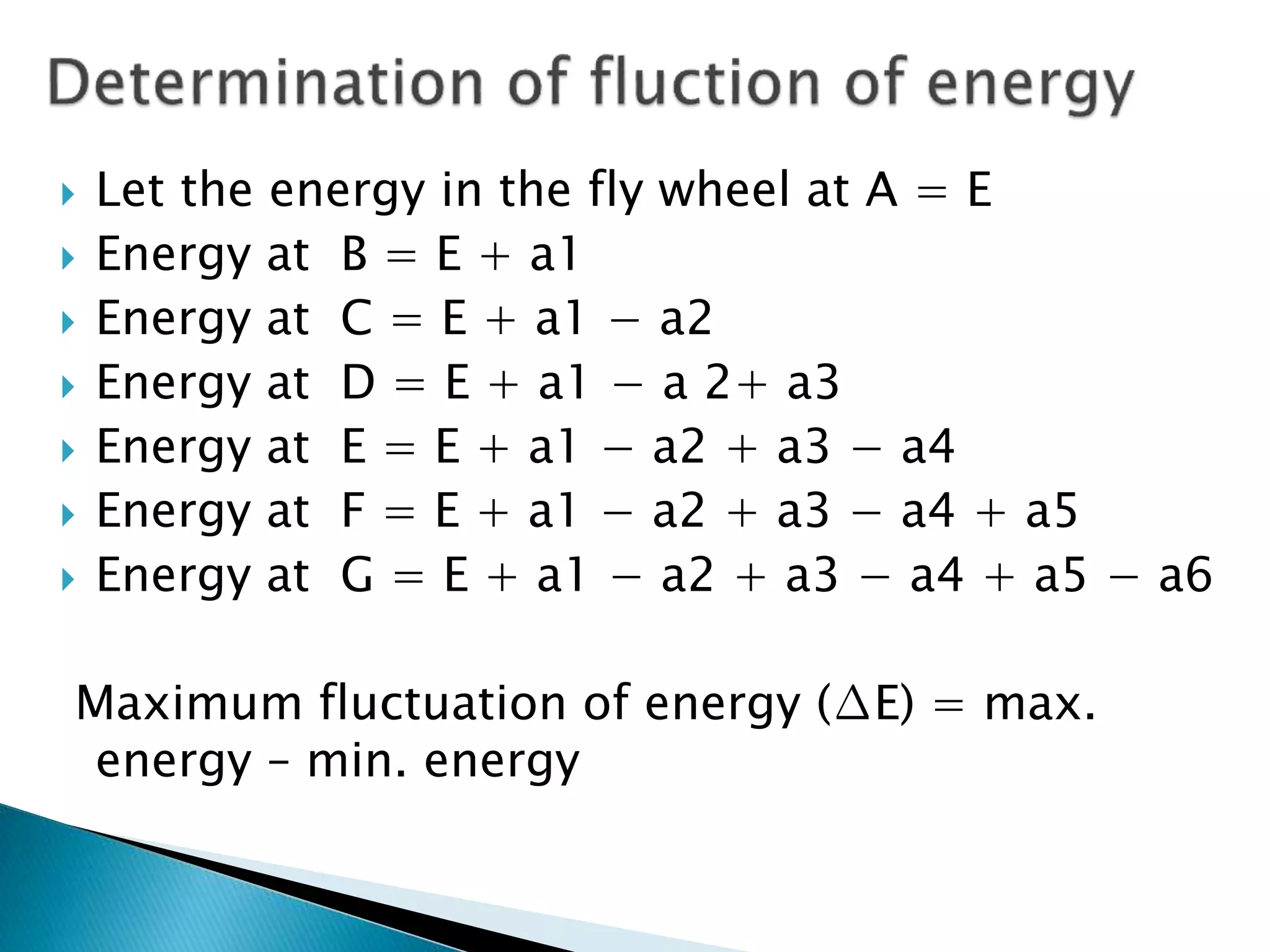

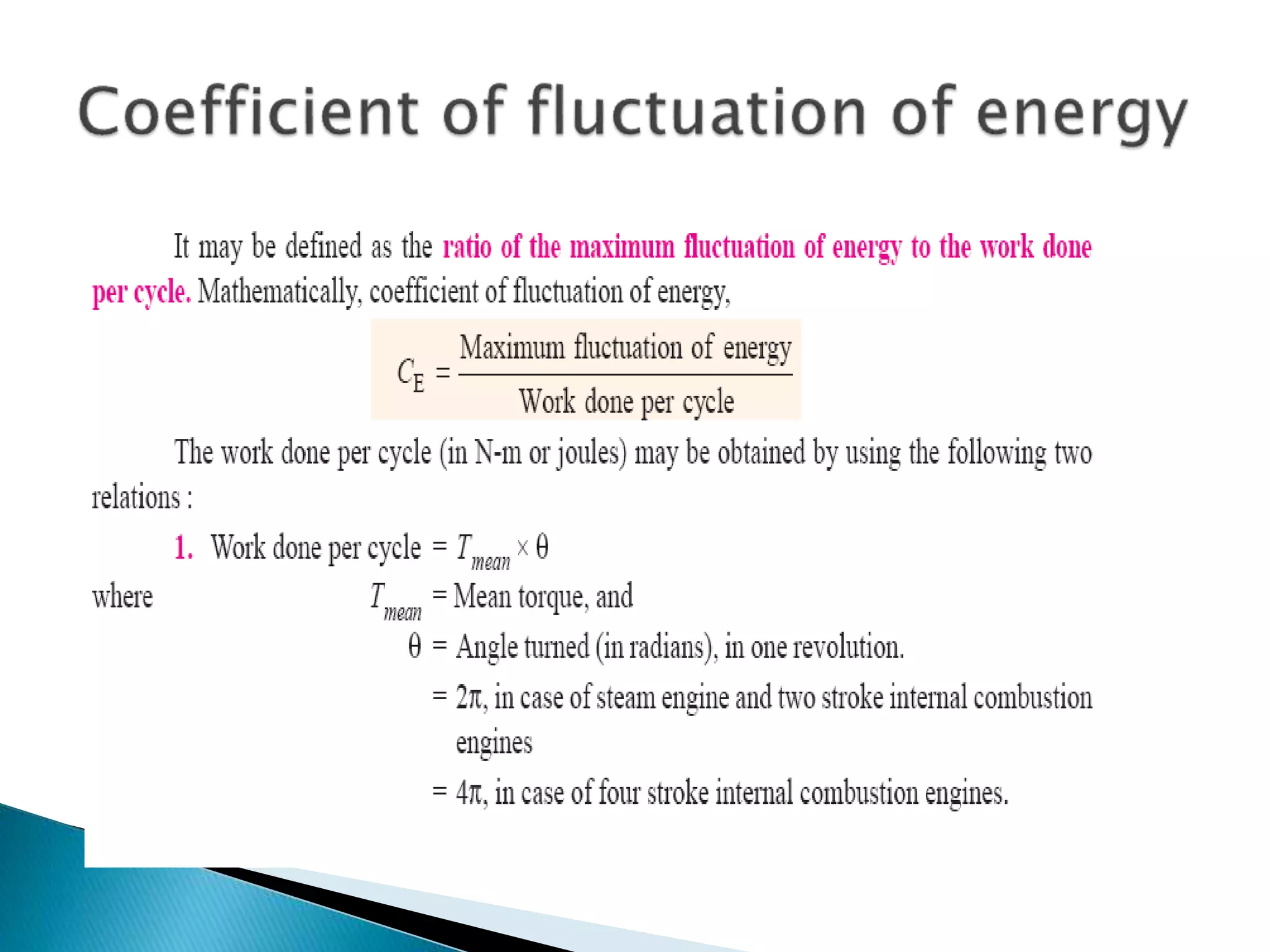

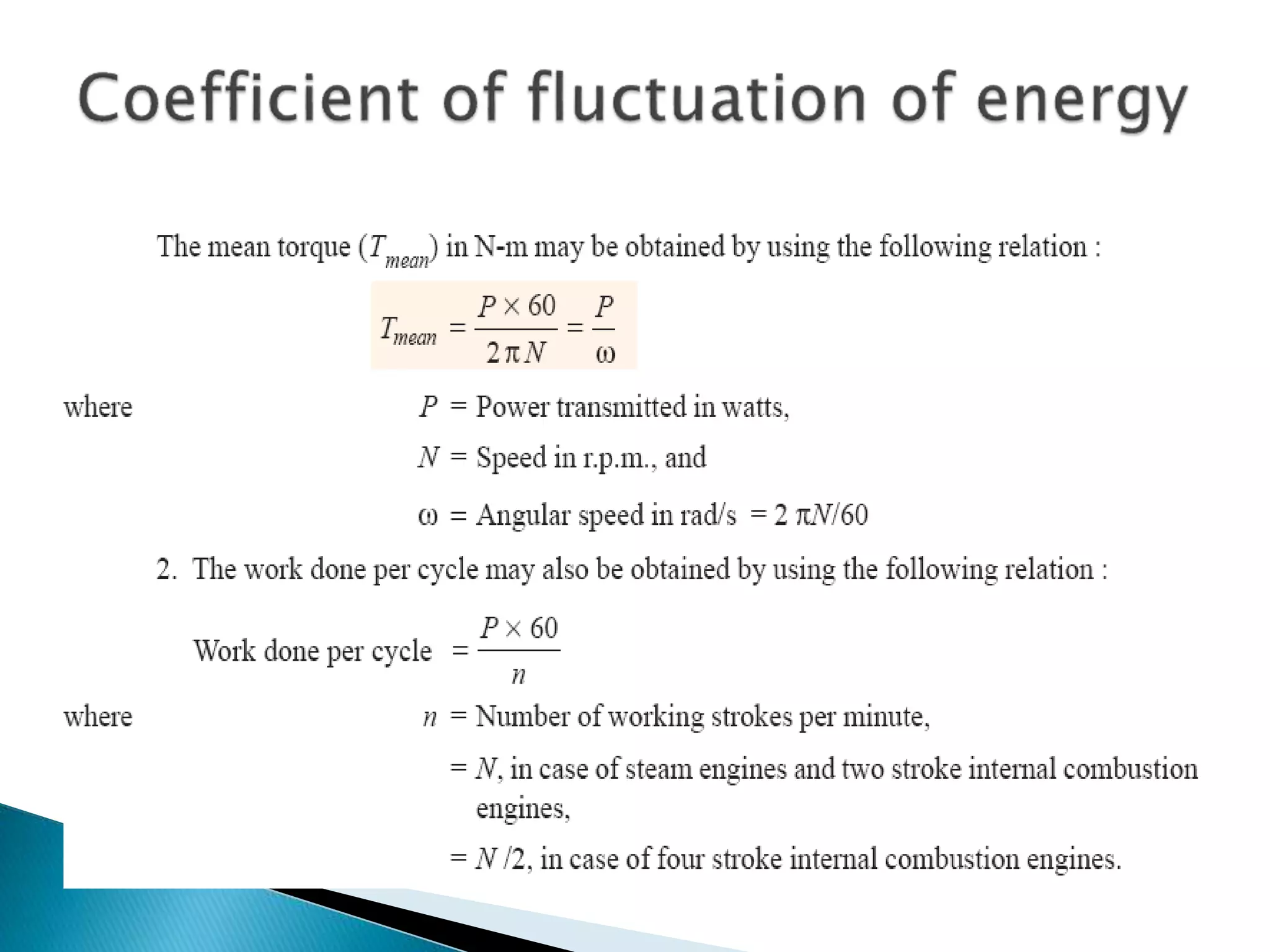

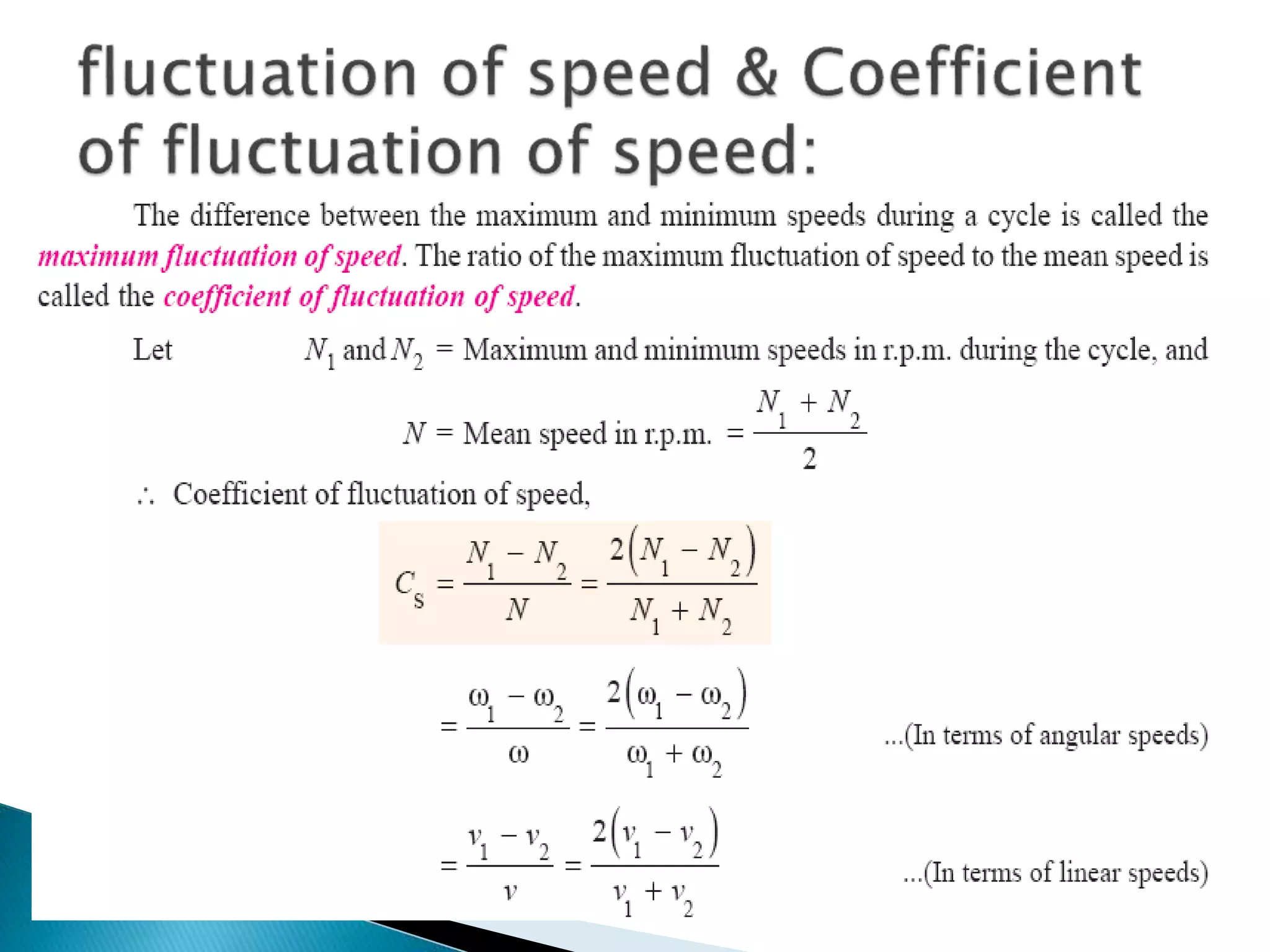

The document discusses force analysis and flywheels. It covers static and dynamic force analysis, including D'Alembert's principle. It also discusses applied forces, inertia, piston effort, crank effort, and crank-pin effort. Flywheels are described as rotating devices that store rotational energy to reduce fluctuations in speed. Turning moment diagrams are discussed as a way to analyze the torque on a crankshaft and determine work, power, mean torque, and maximum torque for engine design. Flywheel sizing is also informed by analyzing energy fluctuations using turning moment diagrams.