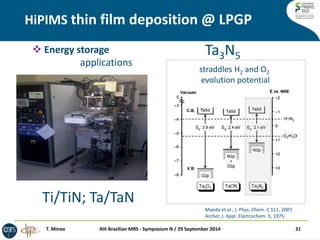

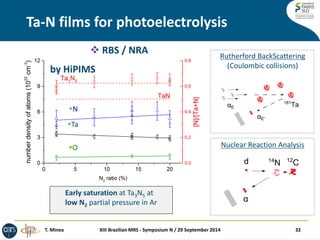

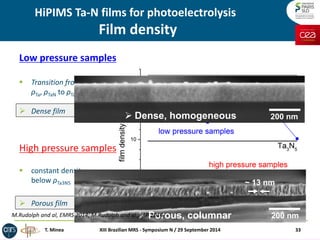

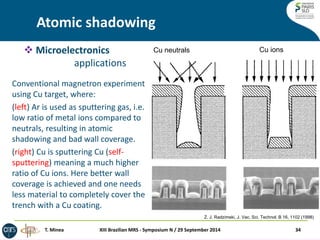

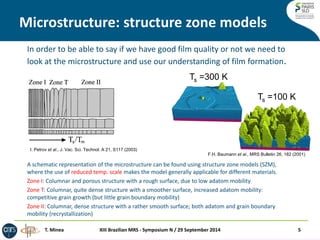

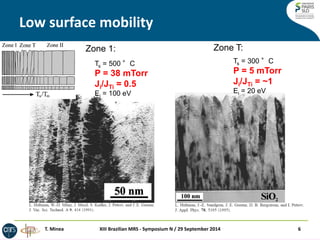

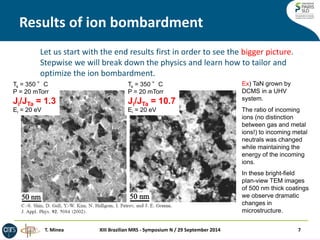

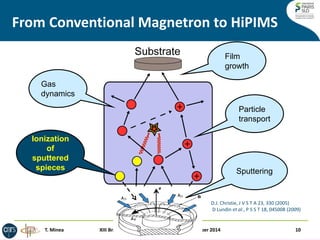

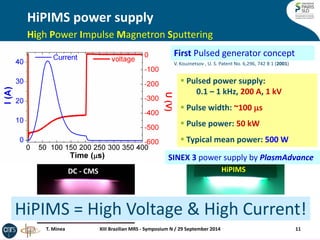

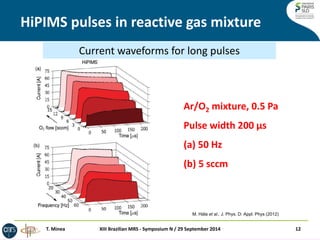

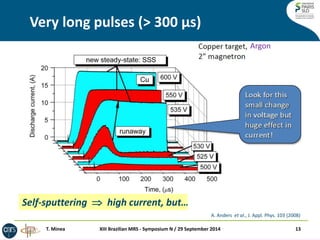

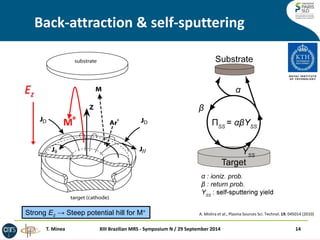

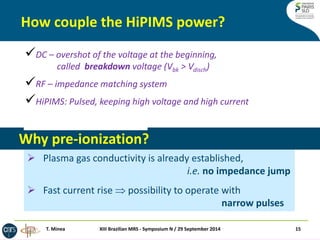

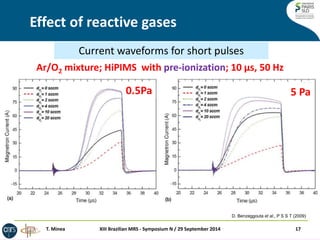

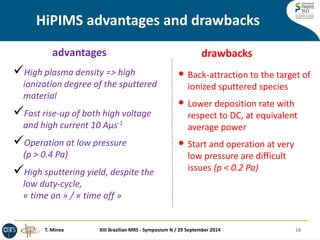

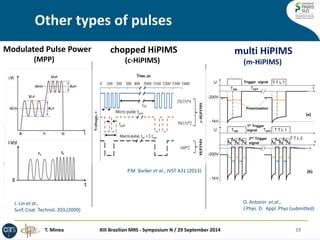

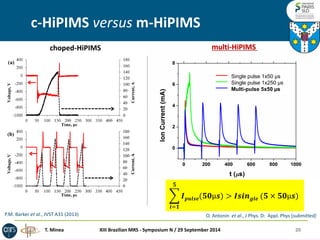

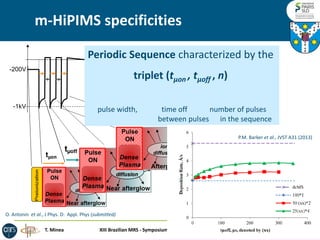

The document discusses high power impulse magnetron sputtering (HIPIMS) technology and its applications in thin film deposition. It outlines the advantages and challenges of HIPIMS, including the importance of precursor ionization, microstructure, and control of deposition parameters. Additionally, it covers recent advances in modeling and experimentation related to HIPIMS processes and the impact of different parameters on film quality.

![Pulse time [μs]

Ganciu et al, US Patent No. 7, 927, 466 B2 (19 April 2011)

Fast HiPIMS with pre-ionization

Average Power 80 W

Pulse width ~10 μs

Frequency < 1kHz

Umax ~ 1kV

Imax ~ 100 A

16

SHORT & FAST Pulsed generator concept [2]; developed 2004

XIII Brazilian MRS - Symposium N / 29 September 2014

T. Minea](https://image.slidesharecdn.com/mineasbpmat29sept2014print-141016090509-conversion-gate02/85/HiPIMS-technology-physics-and-thin-film-applications-16-320.jpg)

![HiPIMS current

XIII Brazilian MRS - Symposium N / 29 September 2014

26

0 2 4 6 8 10

Pulse time [μs]

OHIPIC: Orsay HIgh density plasma Particle-In-Cell model

Experiment using fast pre-ionization HiPIMS

OHIPIC model simulated discharge current

0 1 2 3 4 5 6

Pulse time [μs]

0

-300

- 600

Voltage (V)

Current

T. Minea et al, Surf. Coat. Tech. 255, (2014) 52

T. Minea](https://image.slidesharecdn.com/mineasbpmat29sept2014print-141016090509-conversion-gate02/85/HiPIMS-technology-physics-and-thin-film-applications-26-320.jpg)