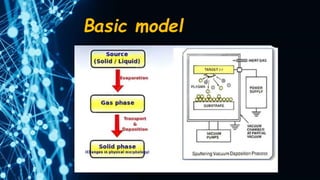

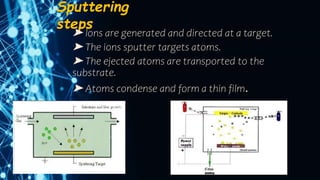

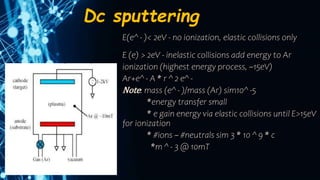

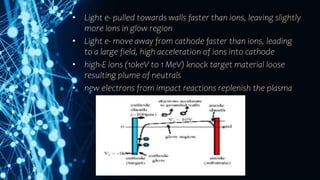

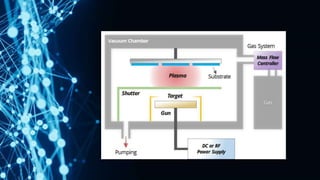

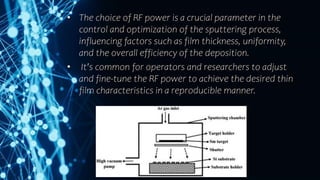

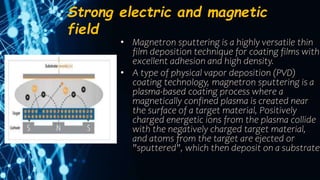

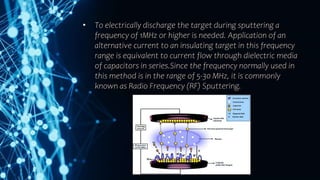

RF sputtering is a sophisticated thin film deposition technique initiated by striking a target material with high-energy ions in a vacuum chamber, enabling the controlled deposition of various materials onto substrates. This method, particularly advantageous for creating uniform films and accommodating different materials, has applications in semiconductor manufacturing, optical coatings, and solar cells. RF sputtering offers benefits like reduced heating and higher deposition rates compared to DC sputtering, although it involves more complex equipment and setup.