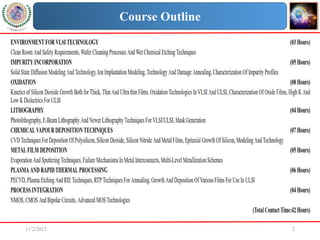

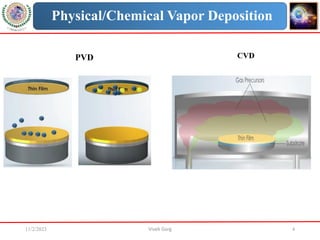

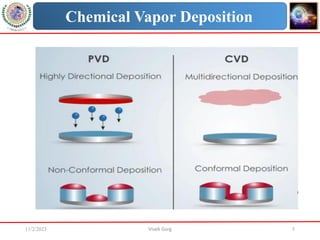

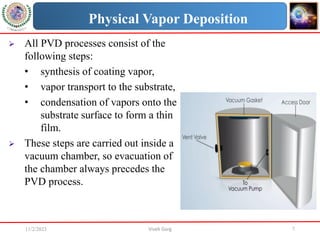

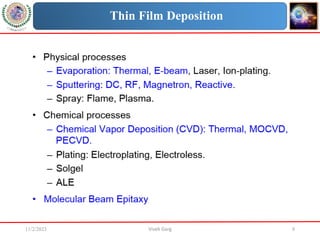

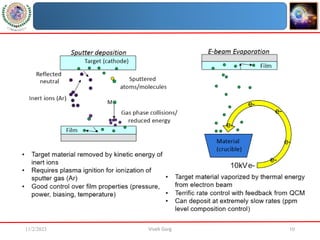

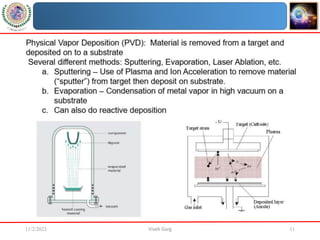

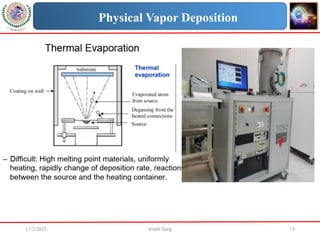

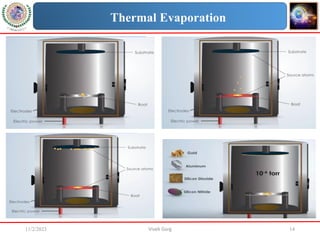

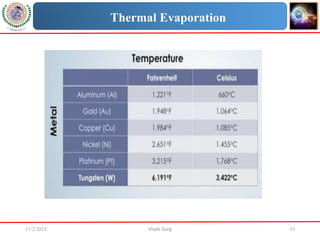

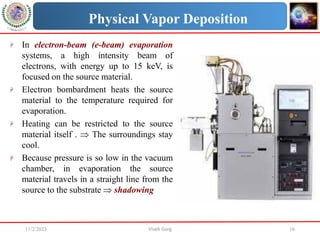

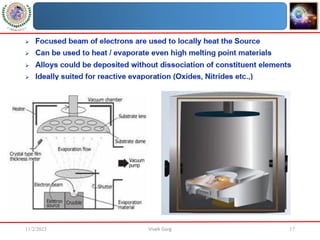

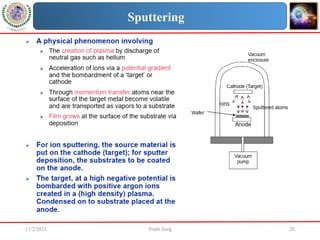

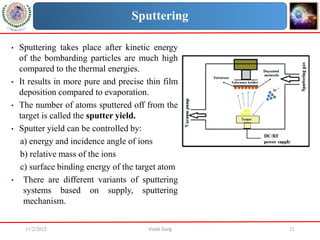

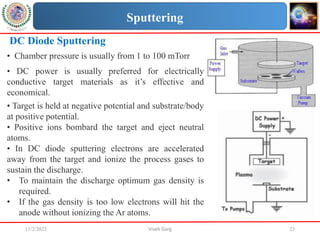

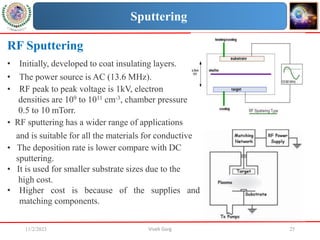

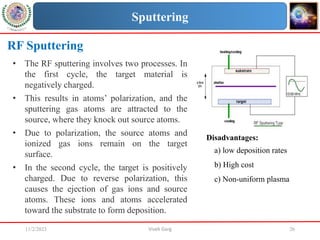

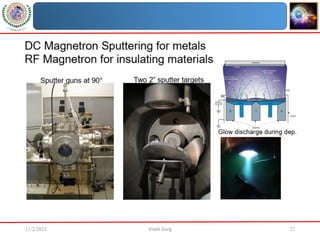

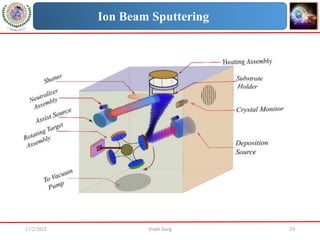

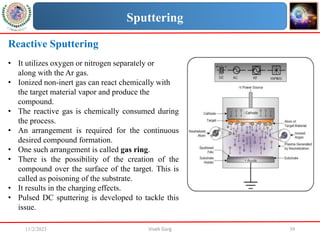

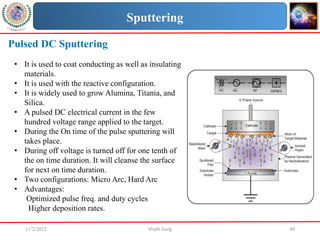

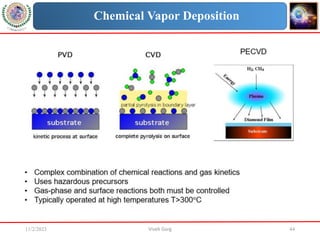

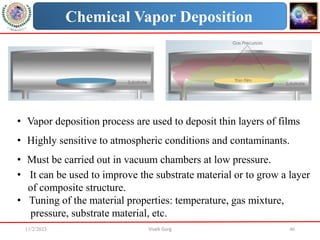

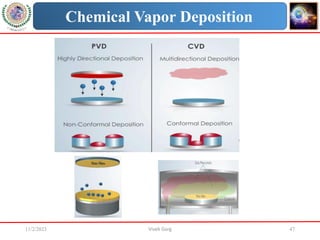

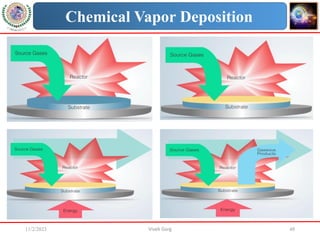

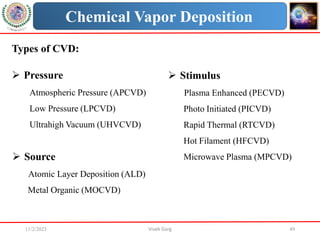

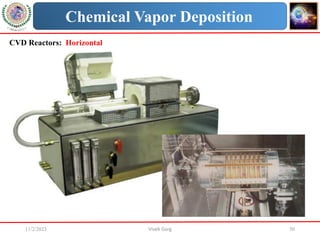

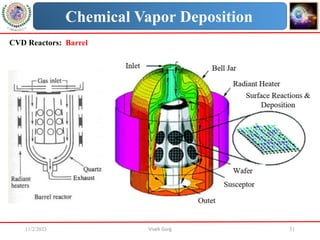

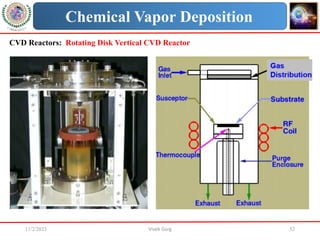

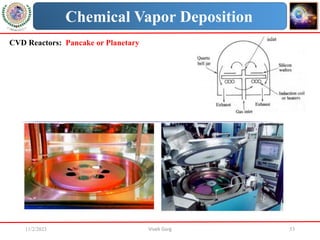

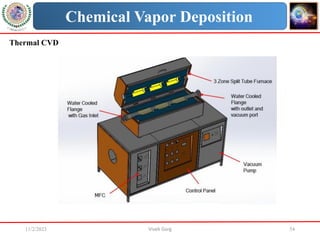

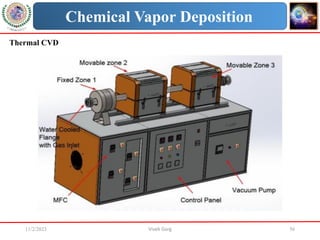

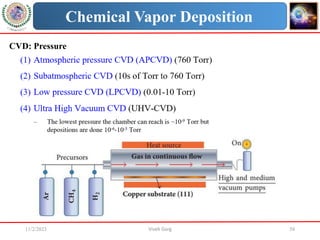

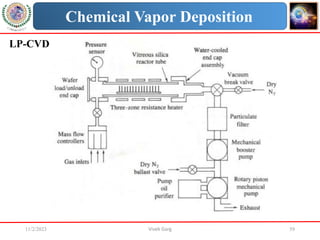

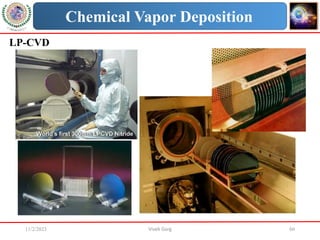

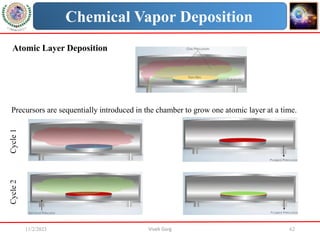

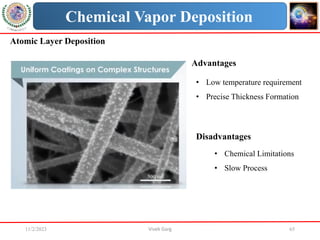

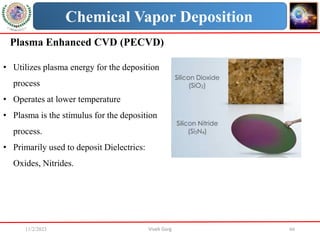

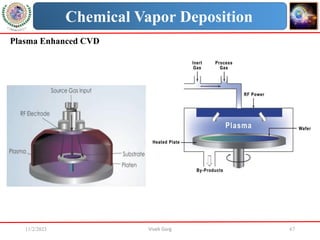

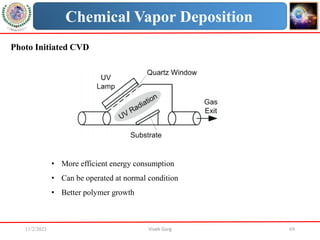

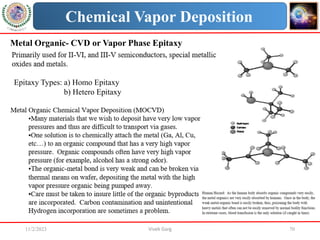

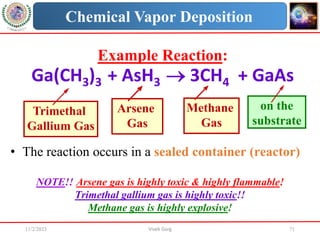

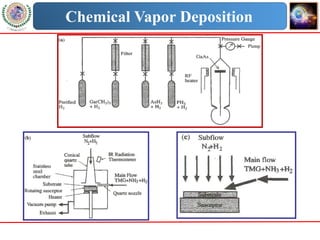

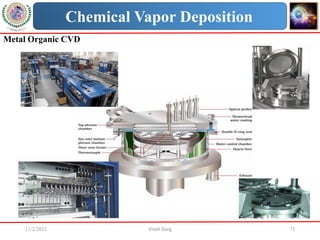

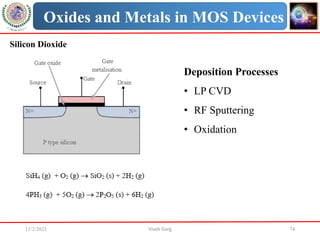

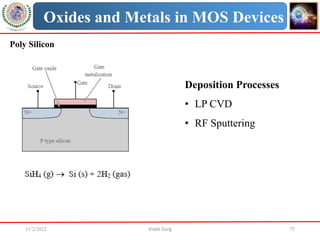

The document covers VLSI technology with a focus on vapor deposition techniques like Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD). It outlines processes such as thermal evaporation, sputtering, and different variants of CVD, detailing equipment, steps involved, and applications in electronics. Additionally, it touches upon challenges and solutions in thin film deposition, including the importance of vacuum conditions and potential chemical hazards.