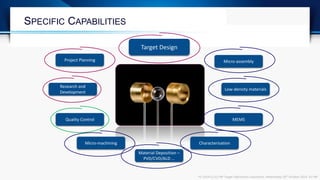

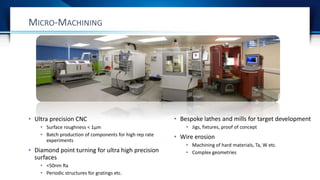

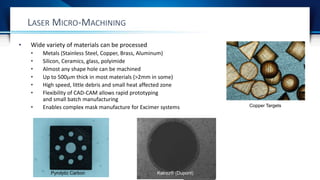

Scitech Precision Ltd is a company that produces microtargets for high power laser systems using multiple technologies. They have over 40 years of experience producing complex targets and provide thousands each year to research groups worldwide. Their capabilities include laser microtarget production, laser micromachining, phase plates, MEMS technologies, thin film deposition, microassembly, and cryogenic targetry. They have dedicated cleanrooms and advanced metrology to guarantee target quality.