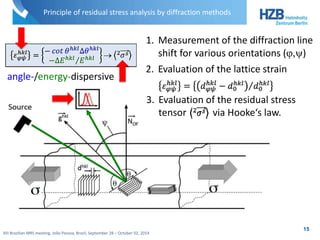

The document presents insights from a presentation on the use of high-energy synchrotron radiation for analyzing stress and microstructure in thin films, focusing on energy-dispersive diffraction techniques. It discusses various applications, including stress analysis on coated cutting tools and the in-situ study of thin film processing, highlighting the importance of diffraction methods for understanding material properties. The overall conclusion emphasizes the versatility of energy-dispersive synchrotron x-ray diffraction in materials science for analyzing residual stresses, film growth, and microstructural characteristics.

![Information provided by X-ray diffraction

X-Ray Diffraction: Crystal structure

Nondestructive

Phase-selective

Information depth nm ... cm

before sulphurization

after

Energy [keV]

Intensity [a. u.]

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

Line position and shift:

Crystal structure

Residual stresses

Line width and shape:

Domain/particle size

Microstrain, lattice defects

Line intensity:

crystallographic texture

Reaction kinetics

Fluorescence lines:

Element distribution

8](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-8-320.jpg)

![Well-known and mainly used: Angle-dispersive X-ray diffraction

0D: Scintillation counter

1D: Position sensitive det.

2D: Channel plate

2q

Photon

source

monochromatic

X-ray beam

coating

E1 = E2 = E3 …

CoKa surface sensitive (low energies)

30 40 50 60 70 80 90

2q [deg]

15

10

5

0

I [cps]

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

high angular resolution

long counting times (scintillation

counter)

complex experimental setup

variable!

substrate

10](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-10-320.jpg)

![„Thin“system (D = 5 μm) „Thick“system (D = 18 μm)

Al2O3

TiCN

0.176

0.174

0.0877

0.0875

as-grown

blasted

as-grown

blasted

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

18

XSA on multilayer systems: Influence of the coating design

WC 5μm

Al2O3

TiCN

WC

10μm

TiCN

0.2 0.4 0.6 0.8 1

0.0873

0

d422 [nm]

sin²y

as-grown

as-grown

0.2 0.4 0.6 0.8 1

0.1745

0.1735

0.1725

0.08760

0.08755

0.08750

0

d422 [nm]

sin²y

blasted

CuKa

Al2O3

0.2 0.4 0.6 0.8 1

0.172

0

d024 [nm]

sin²y

0.2 0.4 0.6 0.8 1

0.1715

0

d024 [nm]

sin²y

blasted

CuKa

steep

stress

gradient!](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-18-320.jpg)

![ED-XSA in the interfacial substrate zone

Al2O3

TiCN

0

- 0.5

-1.0

001

101

110

002

as-grown

blasted

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

2q = 9°

30 40 50 60

1000

800

600

400

200

E [keV]

I [cts]

100-WC

001-WC

101-WC

110-WC

002-WC

111-WC

coating reflections

5μm

WC

E1 < E2 < E3

M. Klaus et al., Thin solid films 517 (2008), 1172.

1 2 3 4 5 6 7

-1.5

001

111

0

s|| [GPa]

[μm]

coating

19

Application of the sin2y-method

to each line Ehkl

Assignment of the obtained

stress values <shkl> to average

information depth <hkl>](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-19-320.jpg)

![Interlayer gradient: Balance between coating and substrate

TiCN

Al2O3

WC 5μm

1 2 3 4 5

Intralayer gradient: Balance within the Al2O3 top layer

TiCN

Al O 3

BL

2

as-grown

blasted

4 8 12 16 20

z [μm]

2

0

- 2

- 4

- 8

2

0

- 2

- 4

- 6

- 8

TiN

0

s|| [GPa]

Al2O3

TiCN

WC

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

10μm

z [μm]

- 6

0

s|| [GPa]

TiCN

TiN

Al O

BL

as-grown

blasted

2 3

001

101

110

002

as-grown

blasted

1 2 3 4 5 6 7

0

- 0.5

-1.0

-1.5

001

111

0

s|| [GPa]

[μm]

001

101

110

002

blasted

1 2 3 5 6 7

0

-0.5

-1.0

-1.5

111

0 4

s|| [MPa]

[μm]

unblasted

Residual stress balance in multilayer systems

20](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-20-320.jpg)

![In-situ microstructure analysis: recrystallization of CuInS2

Substrate temperature [ºC]

50 150 250 350 450

Recrystal-lization

112- CuInS2

10 50 100 150

Process time [min]

Energy [keV]

30

Recrystallized CuInS2

112- CuInS2

Lorentzian,

broad

Gaussian,

small

29 30 31 32 33

Energy [keV]

Energy-dispersive

diffraction line

profile analysis?

H. Rodriguez-Alvarez, PhD thesis, TU Berlin, 2010.

Small-grained,

defective CuInS2

Driving Forces?

Enhancement?

Normalized Intensity [a. u.]

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014 28](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-28-320.jpg)

![Multiple vs. single line analysis

2q = 10°

CeOED Rietveld study of size-related

2 XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

broadening in ceria powder:

EDDI: DV = 226(31) Å+)

Size-Strain RR: DV = 221…236 Å++)

+) D. Apel et al., Z. Kristallogr. 226 (2011), 943.

++) D. Balzar et al., JAC 37 (2004), 911.

112- CuInS2

29 30 31 32 33

Energy [keV]

Normalized Intensity [a. u.]

Energy [keV]

Intensity [counts x 103]

Needs single line

analysis!

30](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-30-320.jpg)

![Single line analysis of domain size and microstrain

Line profiles described by pseudo-Voigt

(pV) functions:

pV(E) = x·Cauchy(E) + (1-x)·Gaussian(E)

(0 x 1)

Domain size Cauchy width bC

Micro strain Gaussian width bG

Broadening angle dispersive energy dispersive

Size

Strain

Size and strain broa-dening

depend on q!

Only strain broade-ning

D. Thomas, PhD thesis, TU Berlin, 2012.

depends on E!

XIII Brazilian MRS meeting, João Pessoa, Brazil, September 28 – October 02, 2014

domain size [nm]

interrupt temperature [°C]

micro strain [%]

initial

state

31](https://image.slidesharecdn.com/sbpmat2014genzeled-diffraction-141007093848-conversion-gate01/85/Thin-films-seen-in-the-light-of-high-energy-synchrotron-radiation-stress-and-microstructure-analysis-using-energy-dispersive-diffraction-31-320.jpg)