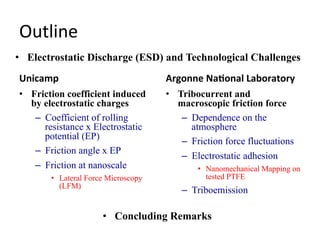

The document discusses the relationship between friction forces and electrostatic charges at material interfaces, emphasizing how electrostatic interactions impact friction at both macroscopic and nanoscale levels. It highlights tribocharging mechanisms, friction coefficient variations due to electrostatic potentials, and safety concerns related to electrostatic discharge in various applications. The concluding remarks suggest potential methods for controlling friction through electrostatic means, indicating further research opportunities in the field of tribology.

![Surfaces

under

rela<ve

mo<on:

Triboplasma

Heinicke G.

Tribochemistry.

(1984)

Matta et al. J.

Phys. D: Appl.

Phys. (2009)

Camara, et al.

Nature (2008)

Burgo, et al.

Polym. Degrad.

Stabil. (2014)

enerated. All these

na follow a certain

plained by Suh [3].

city, normal load,

nt of hydrocarbons

,5], are correlated

s. According to

emission of both

les was measured

ls, ceramics, and

conditions with

ould be considered

y discovered by

s mostly composed

rding to the most

noemission is an

g from mechanical

Fig. 1. General scheme of triboemission [7].

K. Kajdas / Tribology International 38 (2005) 337–353](https://image.slidesharecdn.com/seminriothiago-150922204227-lva1-app6891/85/Friction-Force-and-its-Relationship-to-the-Electrostatic-Charges-at-Interfaces-8-320.jpg)