Embed presentation

Downloaded 22 times

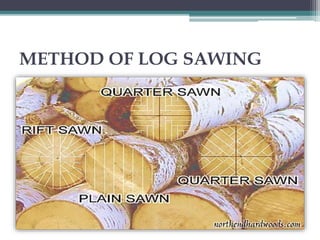

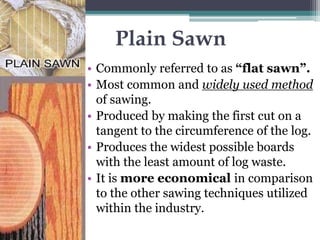

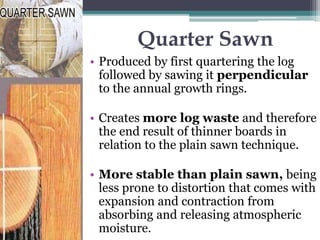

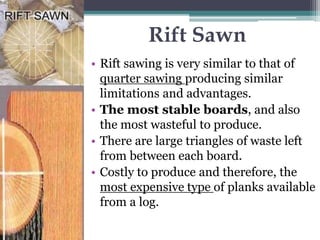

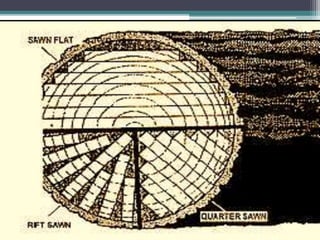

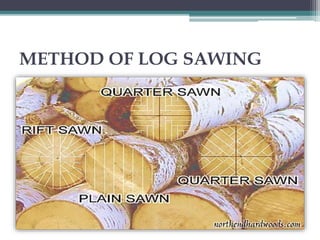

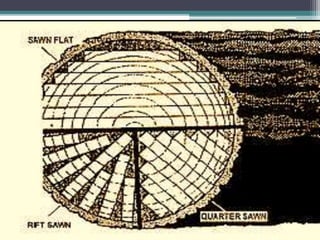

The document describes three common methods of sawing logs: plain sawn, quarter sawn, and rift sawn. Plain sawn produces the widest boards with the least waste but is less stable. Quarter sawn and rift sawn produce more stable boards that resist warping but are more wasteful to produce. Rift sawn is the most stable but also the most expensive due to the high amount of waste.