The document discusses hollow concrete blocks used in construction. Some key points:

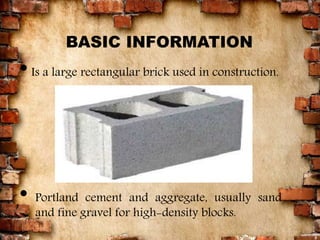

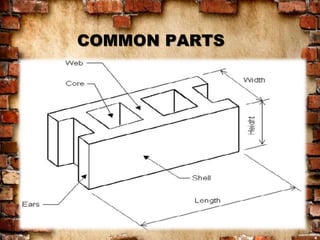

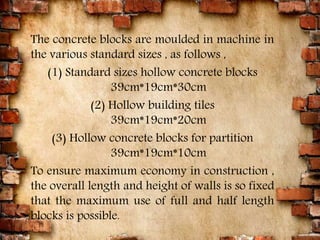

- Hollow concrete blocks are large rectangular bricks made of Portland cement, sand, and gravel aggregates. They come in various standard sizes for different uses.

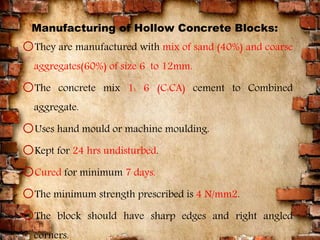

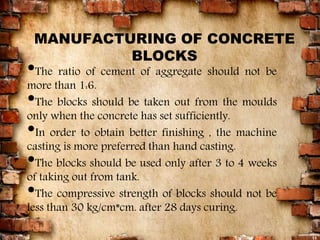

- Blocks are manufactured using a cement to aggregate ratio of 1:6, with sand and gravel aggregates sized 6-12mm. They are molded, cured for 7 days, and should have a minimum compressive strength of 4N/mm2.

- Advantages of hollow concrete block masonry include lighter weight for easier handling, faster construction, and increased floor area due to thinner walls.