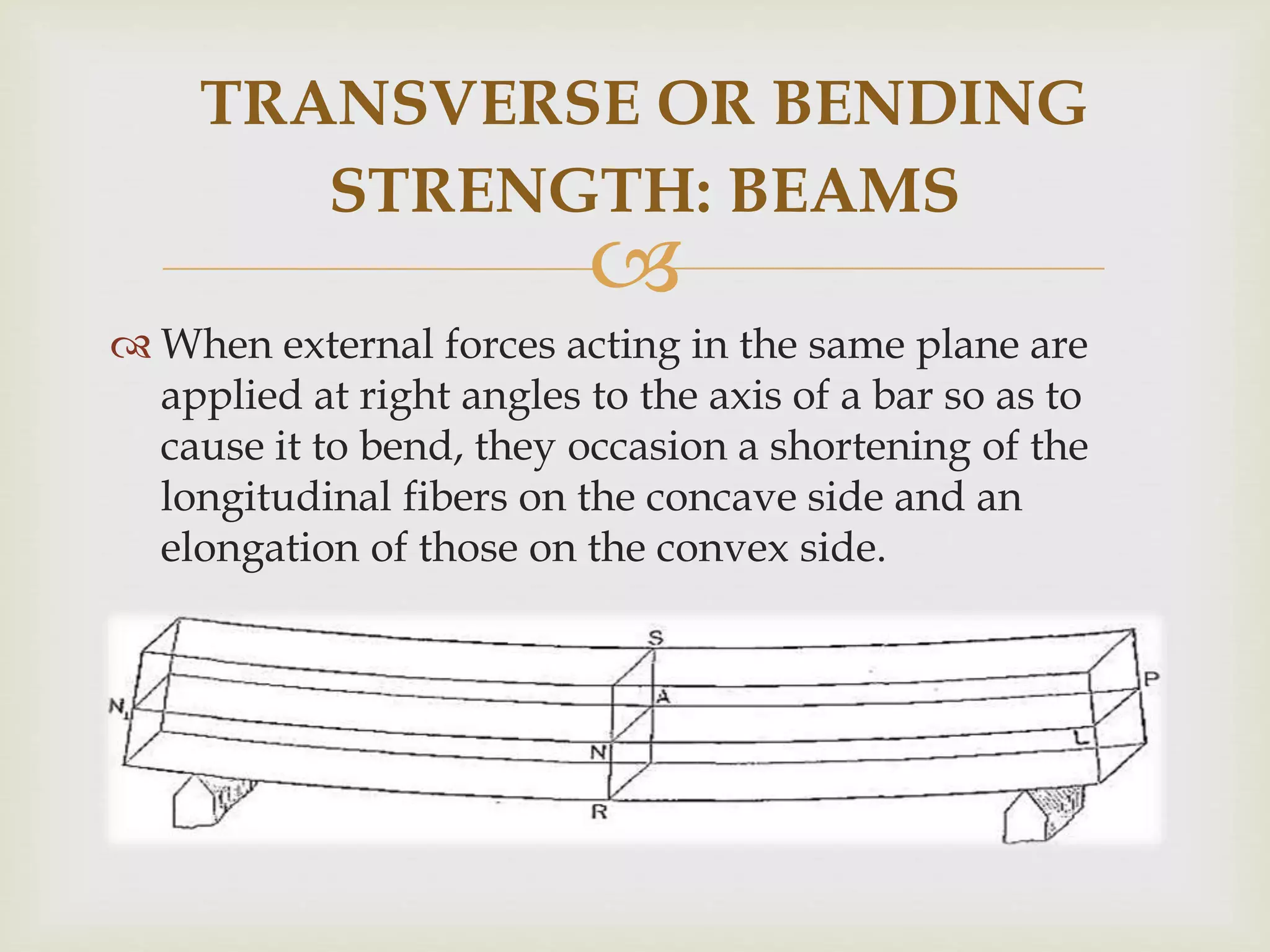

This document defines and describes the various mechanical properties of wood, including stiffness, tensile strength, compressive strength, shearing strength, bending strength, toughness, hardness, cleavability, and resilience. It provides details on how each property is measured and how it impacts the performance and uses of wood. The properties consider how wood resists both internal and external forces acting parallel or perpendicular to the wood grain.