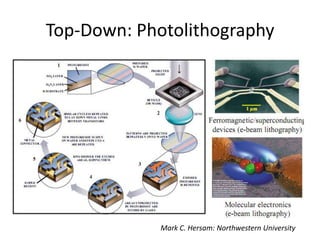

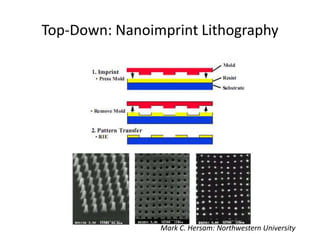

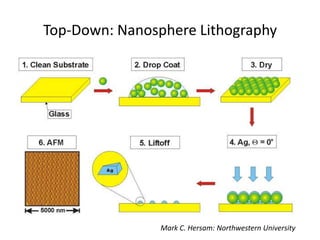

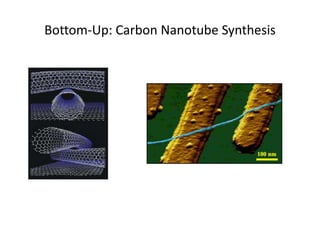

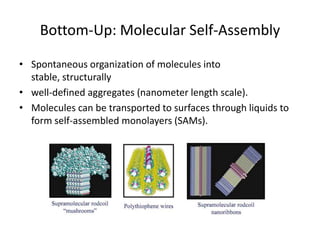

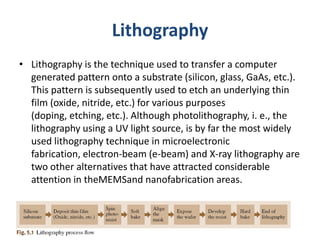

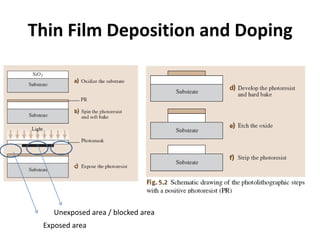

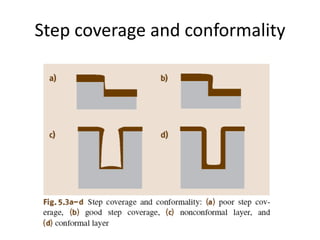

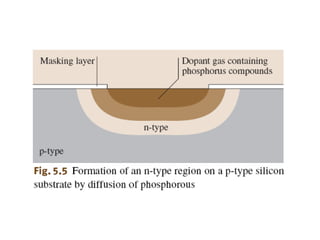

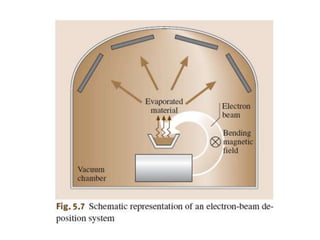

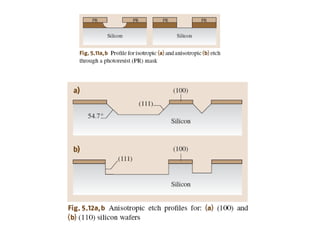

The document discusses microfabrication techniques used to manufacture structures at the nanoscale. It describes both top-down approaches that involve removing material using lithography and etching, as well as bottom-up techniques like self-assembly that build up structures from smaller components. Key microfabrication processes covered include thin film deposition, doping, etching, and lithographic patterning methods like photolithography and imprint lithography. Both isotropic wet etching and highly directional dry etching techniques are also summarized.