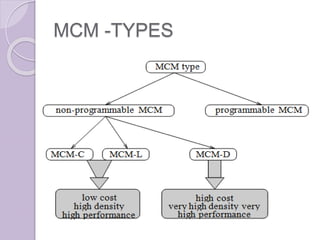

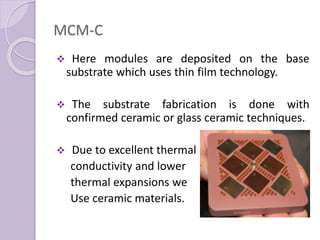

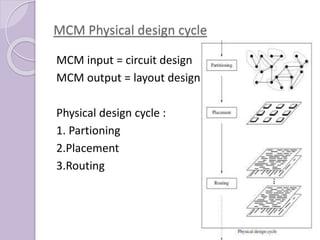

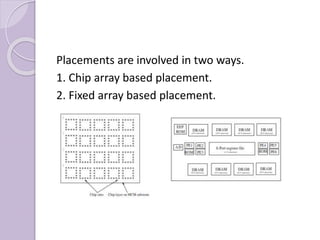

MCM (Multiple-chip-module) packages multiple integrated circuits and semiconductor dies onto a single substrate. There are different types of MCMs based on the substrate material, including MCM-L which uses a laminated substrate, MCM-C which uses a ceramic substrate, and MCM-D which uses a deposited substrate with thin-film metals and dielectrics. The physical design of an MCM involves partitioning the circuit, placing the chips on the substrate while considering timing constraints, power constraints, and thermal characteristics, and routing the interconnects between chips.