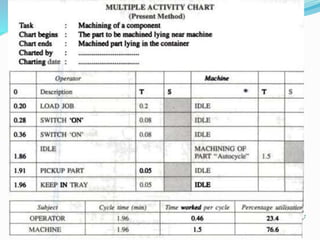

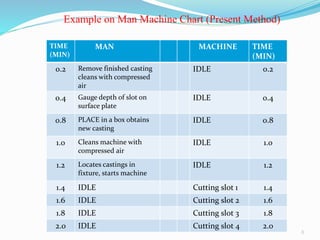

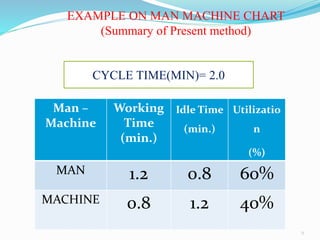

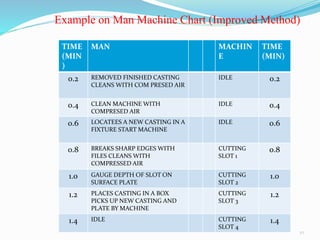

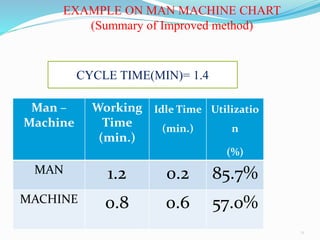

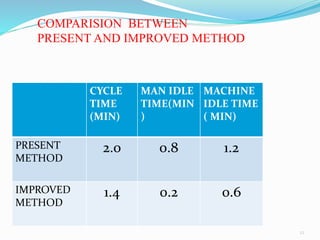

The worker and machine process chart (Man-machine chart) shows the exact time relationship between the working cycle of a person and the operating cycle of a machine at a specific workstation. It can be used to detect idle time on machines and workers, optimize work distribution, and decide the appropriate number of workers. The example shows a man-machine chart for the current and improved methods of a casting production process. The improved method reduces the cycle time from 2 minutes to 1.4 minutes by decreasing the idle times for both the worker from 0.8 to 0.2 minutes and the machine from 1.2 to 0.6 minutes.