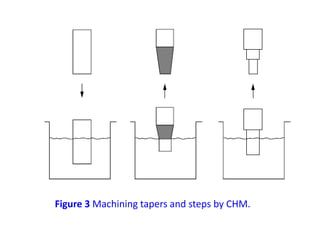

Chemical milling (CHM) is a process that uses controlled chemical dissolution to remove material from a workpiece. It involves masking areas not to be removed, then immersing the workpiece in an etching solution to dissolve the exposed material. Key steps are masking, scribing the mask to expose areas for etching, immersing in etchant, and removing the mask. Factors like etchant type/concentration, temperature, material properties, and process parameters influence the etch rate and surface finish. With proper controls, CHM can produce pockets, contours and complex shapes to tight tolerances and surface roughness of 0.1-0.8 μm.