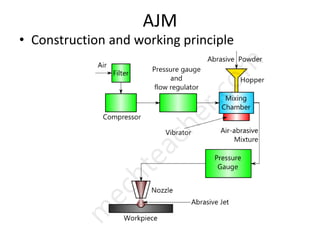

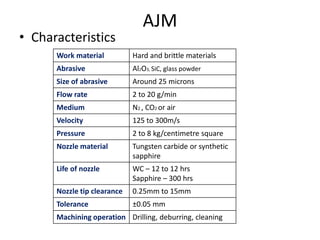

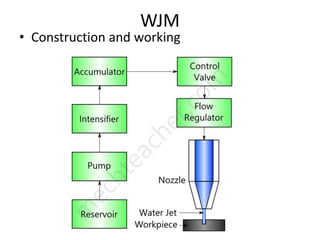

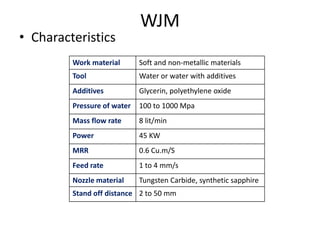

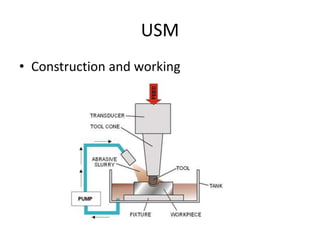

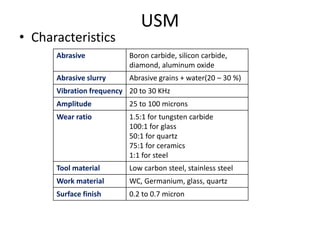

The document discusses three mechanical energy-based machining processes: abrasive jet machining (AJM), water jet machining (WJM), and ultrasonic machining (USM). In AJM, a high-speed stream of abrasive particles erodes material from the workpiece. WJM uses a high-velocity water jet to convert kinetic energy into pressure that removes small chips. USM forces an abrasive slurry against the workpiece using a vibrating tool to remove extremely small chips. Key parameters for each process include abrasive properties, pressure, velocity, vibration frequency, and more. Each method can machine hard materials and provides advantages like avoiding heat, being noiseless, or enabling intricate shapes.