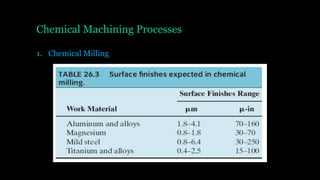

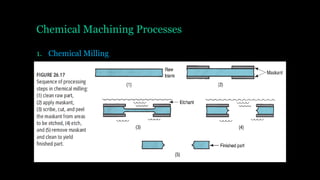

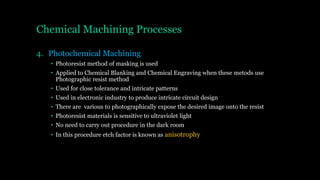

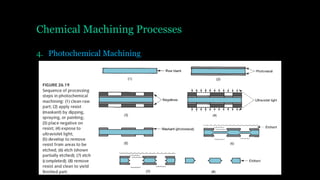

The document provides an overview of chemical machining, a non-traditional method for material removal that produces high-quality parts, including its definition, history, and various processes such as chemical milling, blanking, engraving, and photochemical machining. It details the chemistry involved in the process, including cleaning, masking, etching, and demasking, along with various masking techniques and their specific tolerances. Additionally, it highlights the etching process, including etchant selection and material removal rates, applicable mostly in the aircraft and electronics industries.