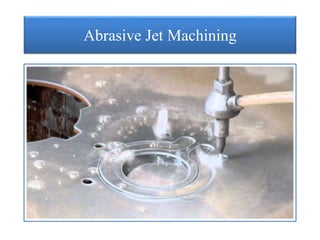

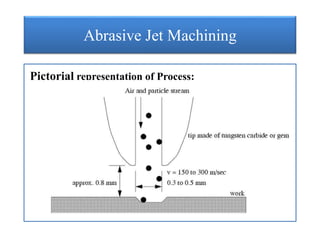

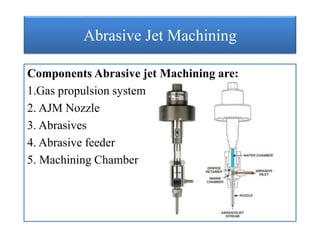

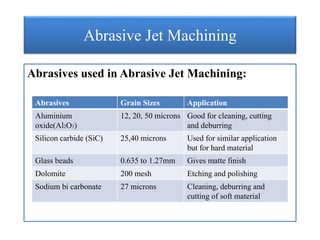

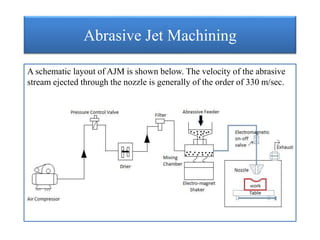

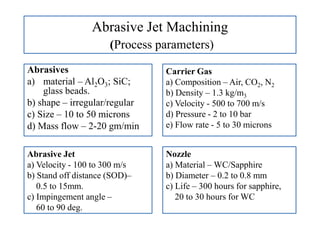

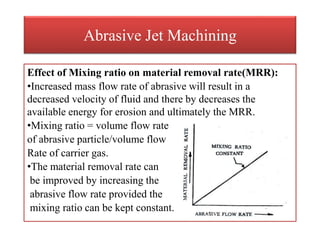

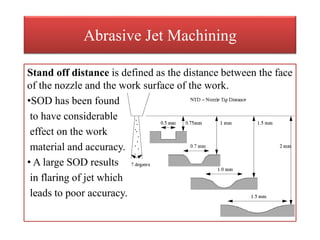

The document discusses abrasive jet machining, which uses a high-velocity stream of abrasive particles carried by compressed air or gas to erode material through micro-cutting and brittle fracture. It describes the process, components, process parameters like abrasives, carrier gas, and nozzle used. Applications include cutting brittle materials like glass, ceramics, and silicon. Key advantages are cool cutting of heat-sensitive materials and high surface finish quality.