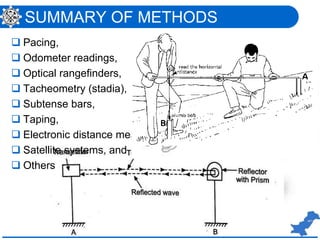

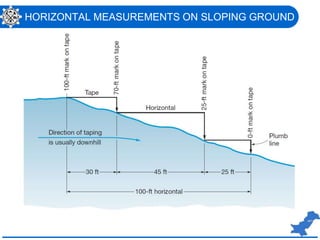

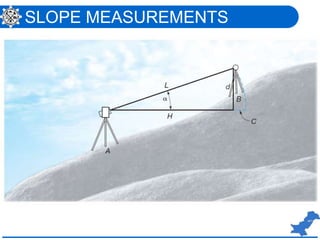

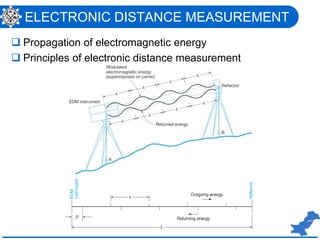

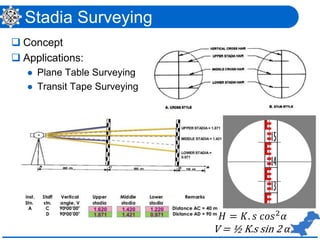

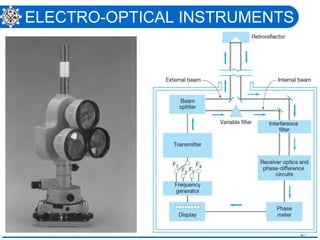

This document discusses various methods for measuring distances in surveying, including taping, electronic distance measurement (EDM), and satellite systems. It focuses on taping equipment such as steel, Invar, and fiberglass tapes; accessories like pins, hand levels, and tension handles; and factors that can introduce errors like temperature, tension, and sag. It also covers EDM principles, total stations, and sources of errors in electronic distance measurement.