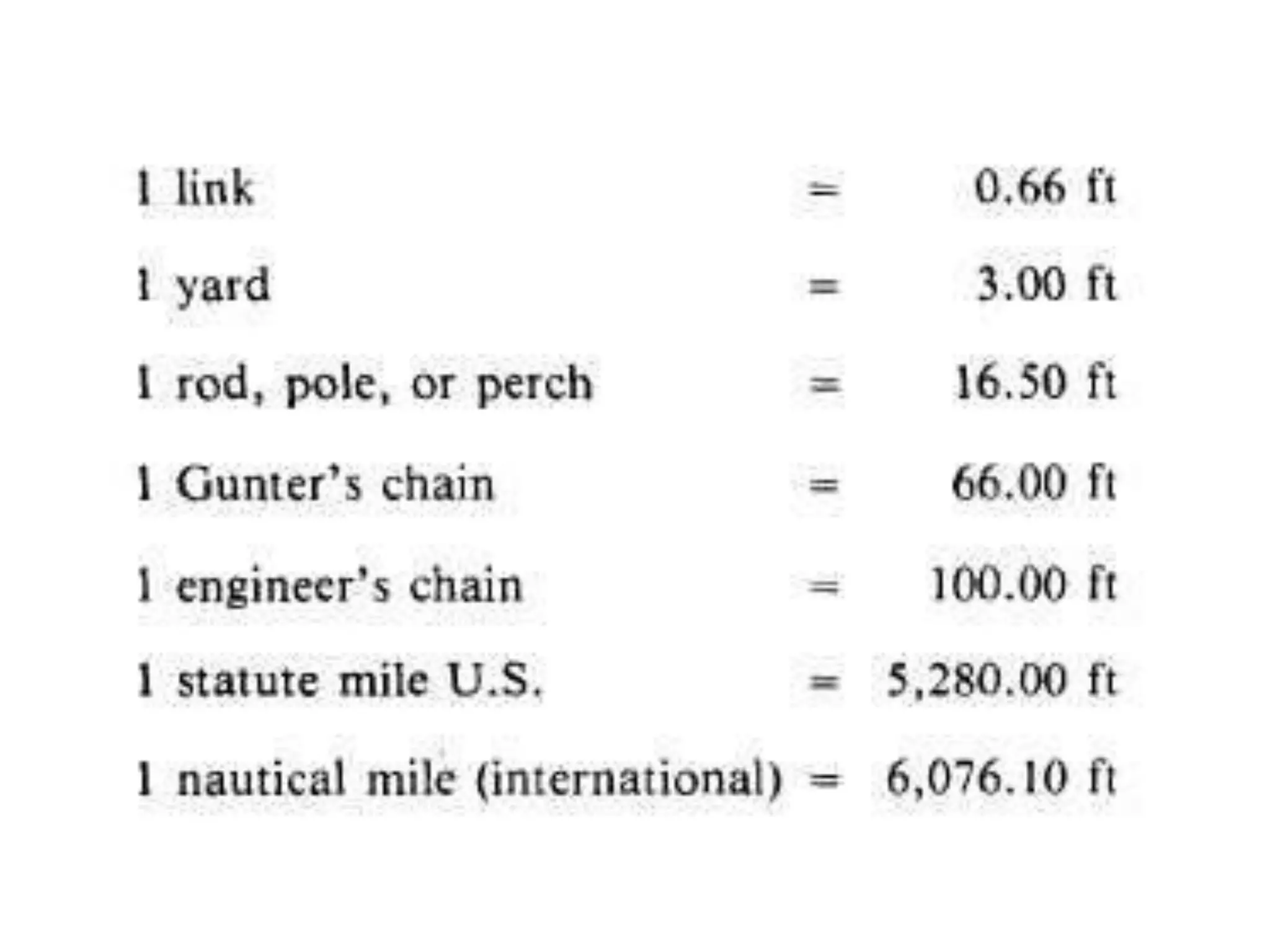

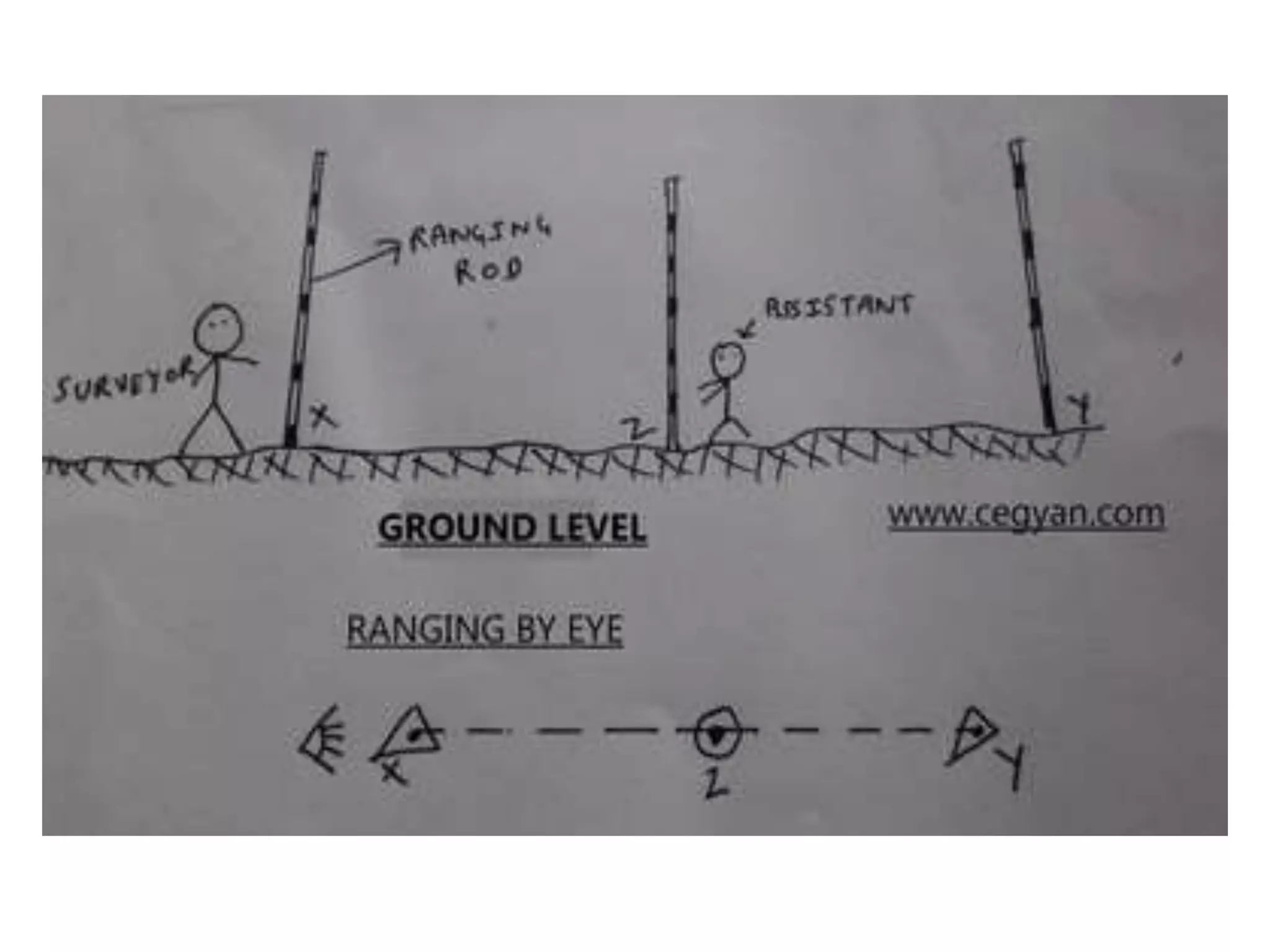

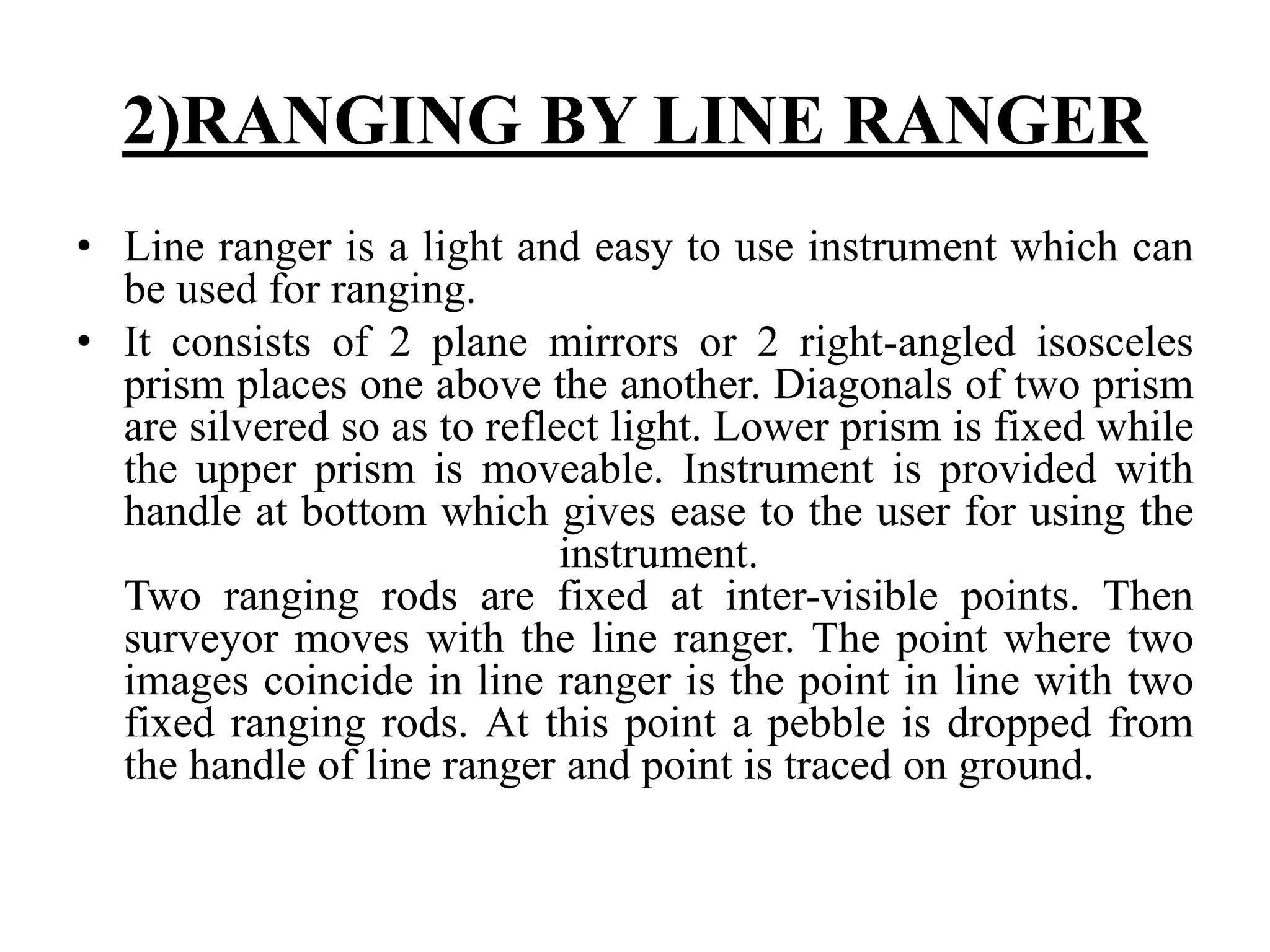

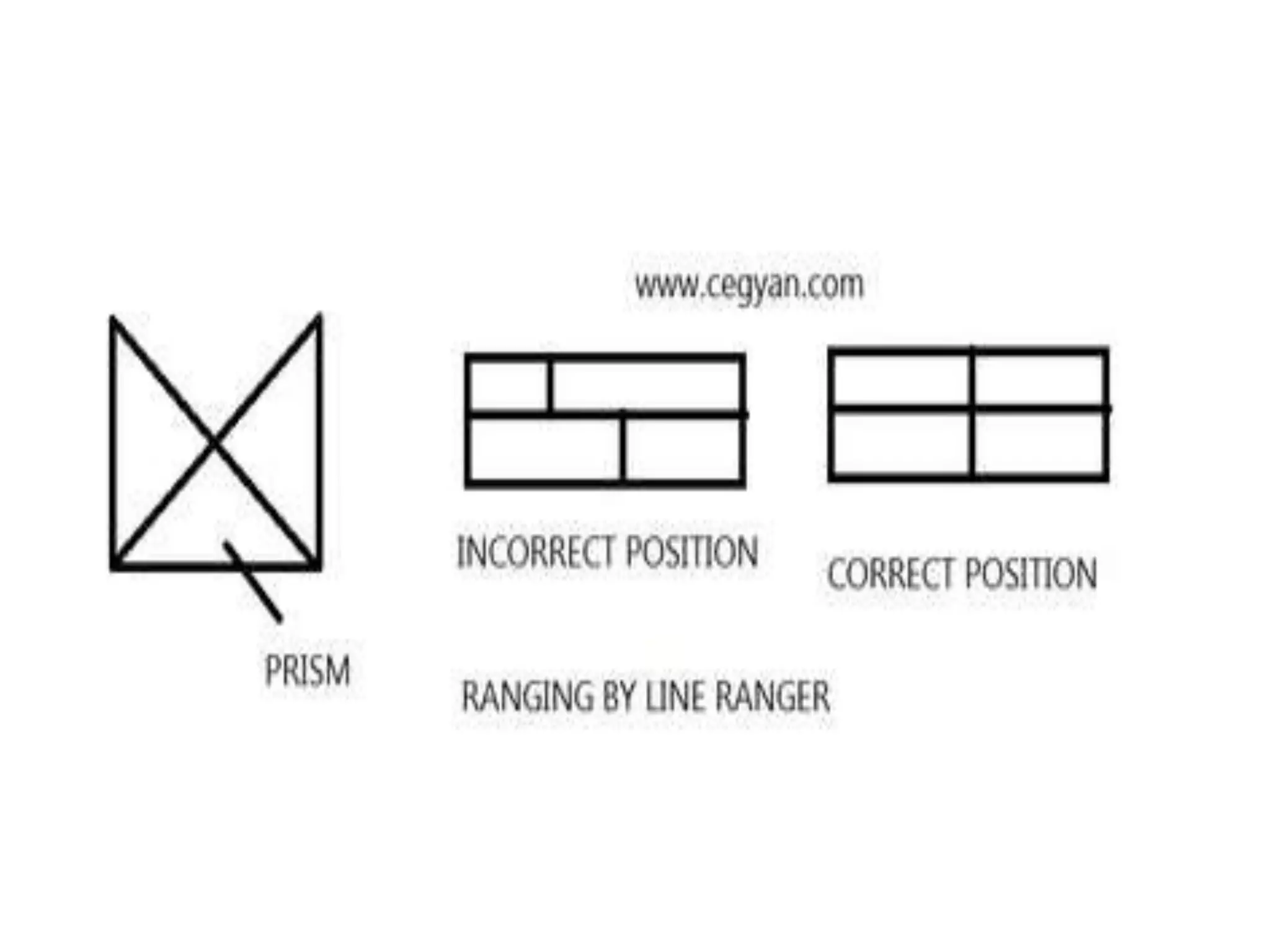

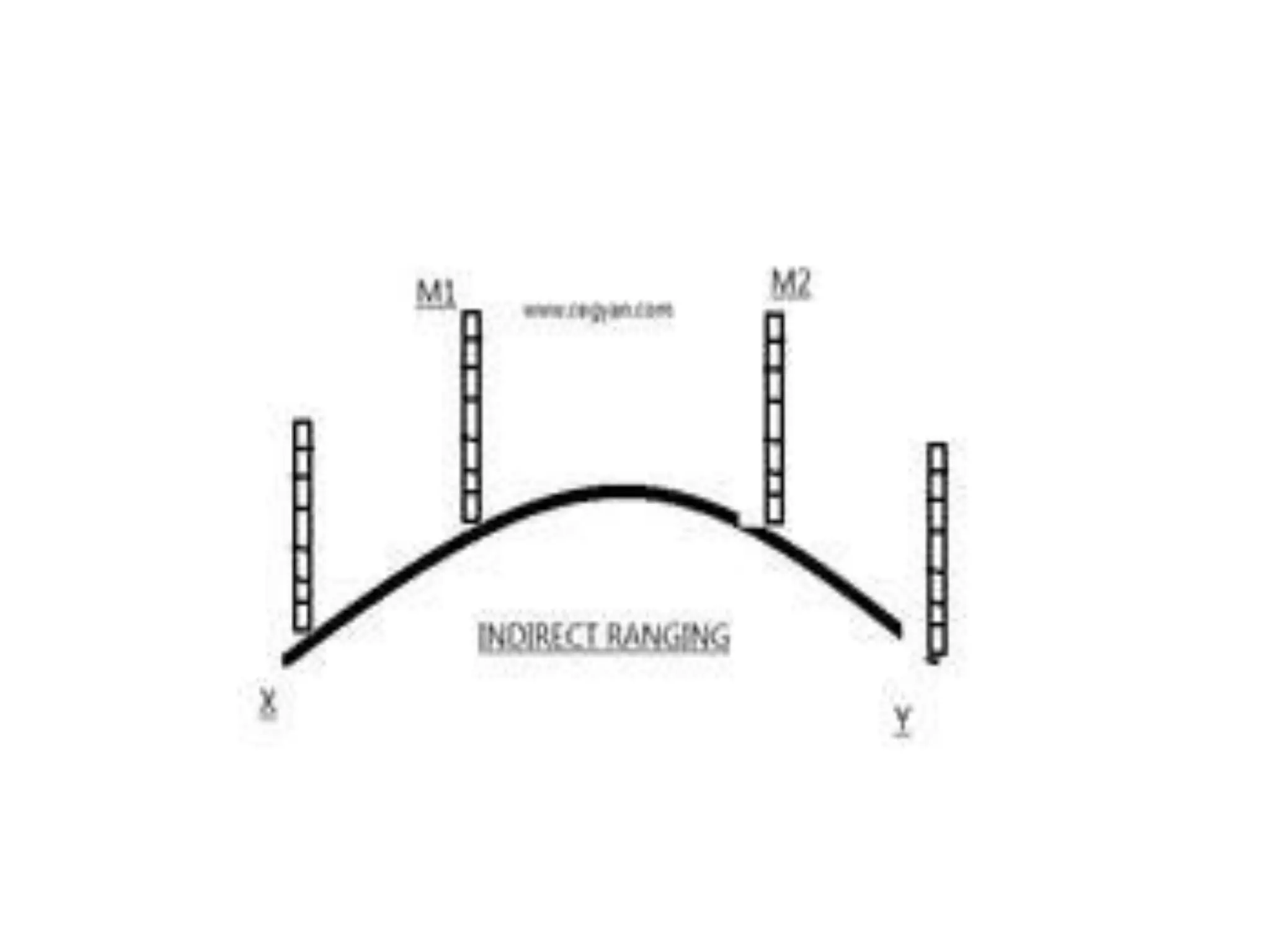

This document discusses various methods of linear measurement used in surveying. It describes chain and tape measurements, including different types of chains, steel bands, and tapes. It also discusses direct and indirect methods of ranging out survey lines when stations are visible or not visible to each other. Finally, it summarizes direct and indirect methods of chaining on sloping ground, including stepping, hypotenuse allowance, and applying slope corrections.