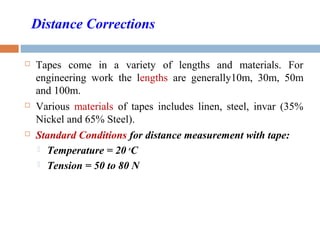

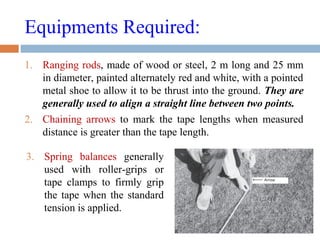

The document discusses various corrections that must be applied to distance measurements taken with tapes. It describes 6 types of corrections:

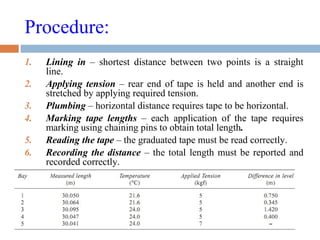

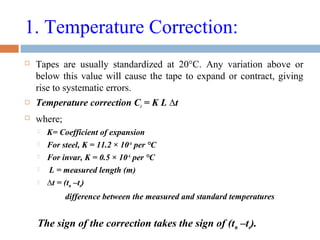

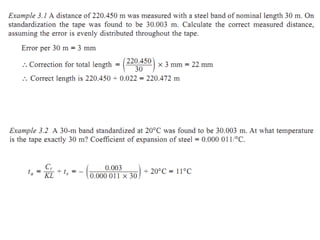

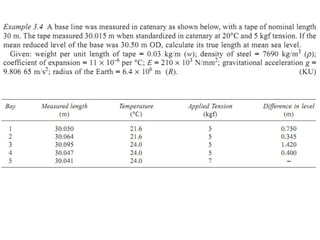

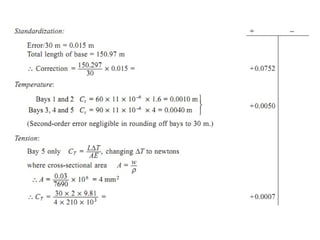

1. Temperature corrections account for tape expansion or contraction due to temperatures different from the standard 20°C measurement condition.

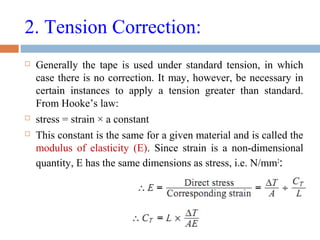

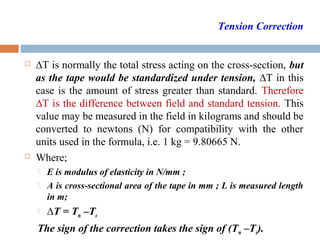

2. Tension corrections account for differences between the applied tension and standard tension used during tape calibration.

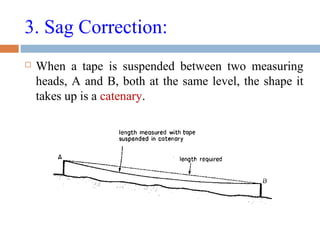

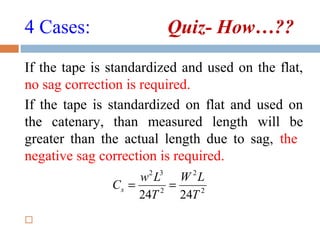

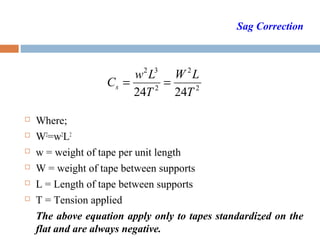

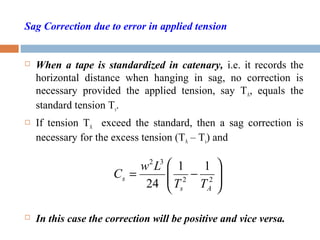

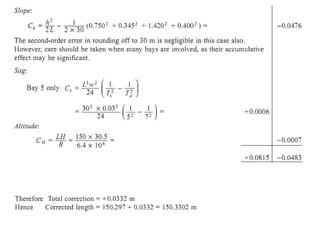

3. Sag corrections account for the catenary shape of a tape suspended between two points and ensure the measured distance matches the horizontal distance.

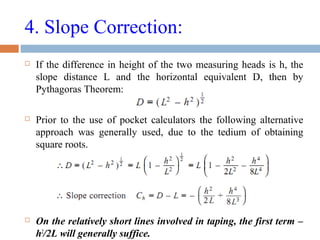

4. Slope corrections convert measured sloped distances to equivalent horizontal distances.

5. Standardization corrections account for tape length changes due to use over time.

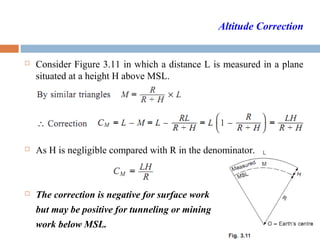

6. Altitude corrections reduce measured distances to a standard