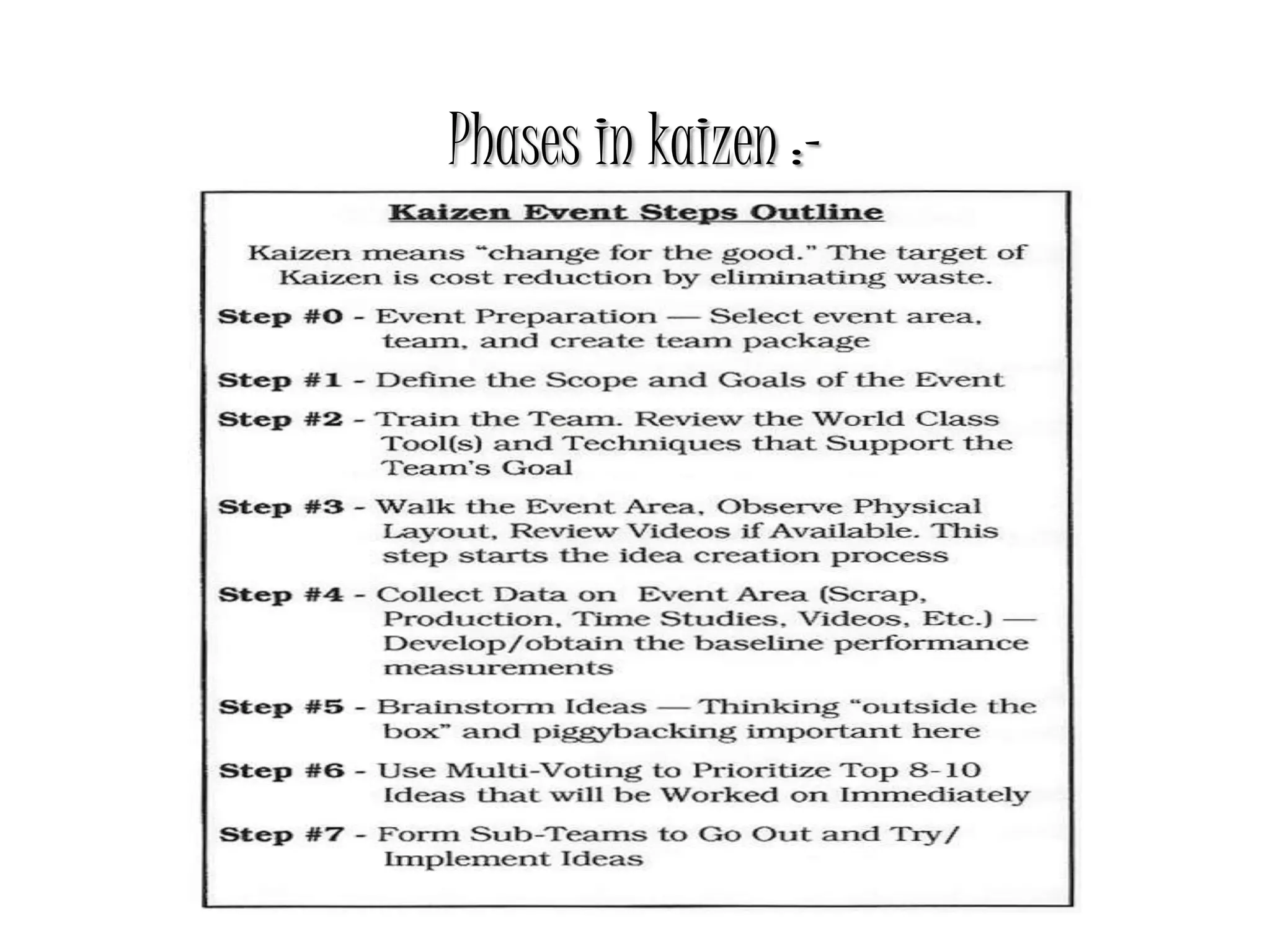

The document discusses Kaizen, a Japanese philosophy of continuous improvement. Some key points:

- Kaizen focuses on making small, incremental changes to improve productivity and minimize waste. It involves all employees and little cost.

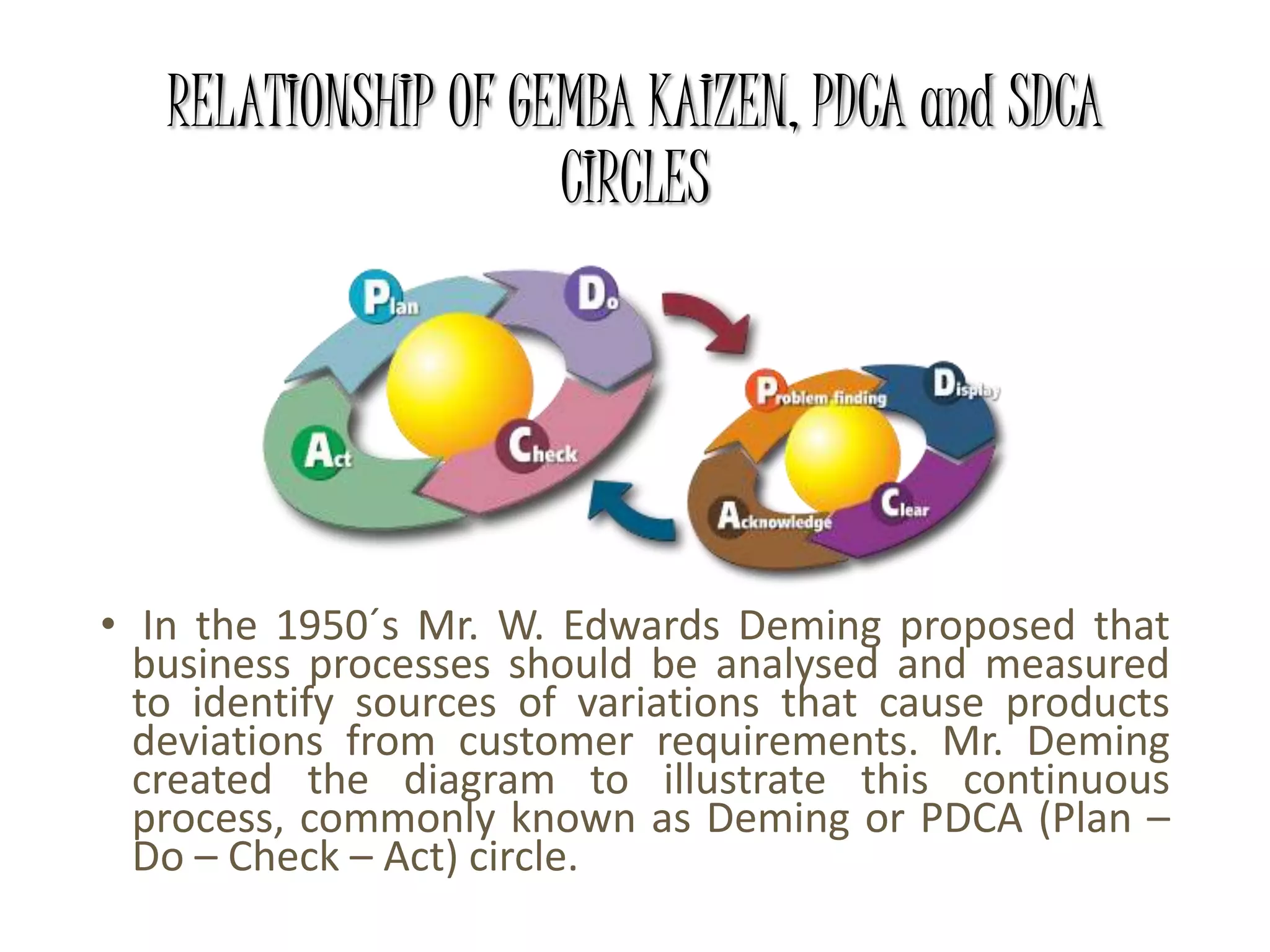

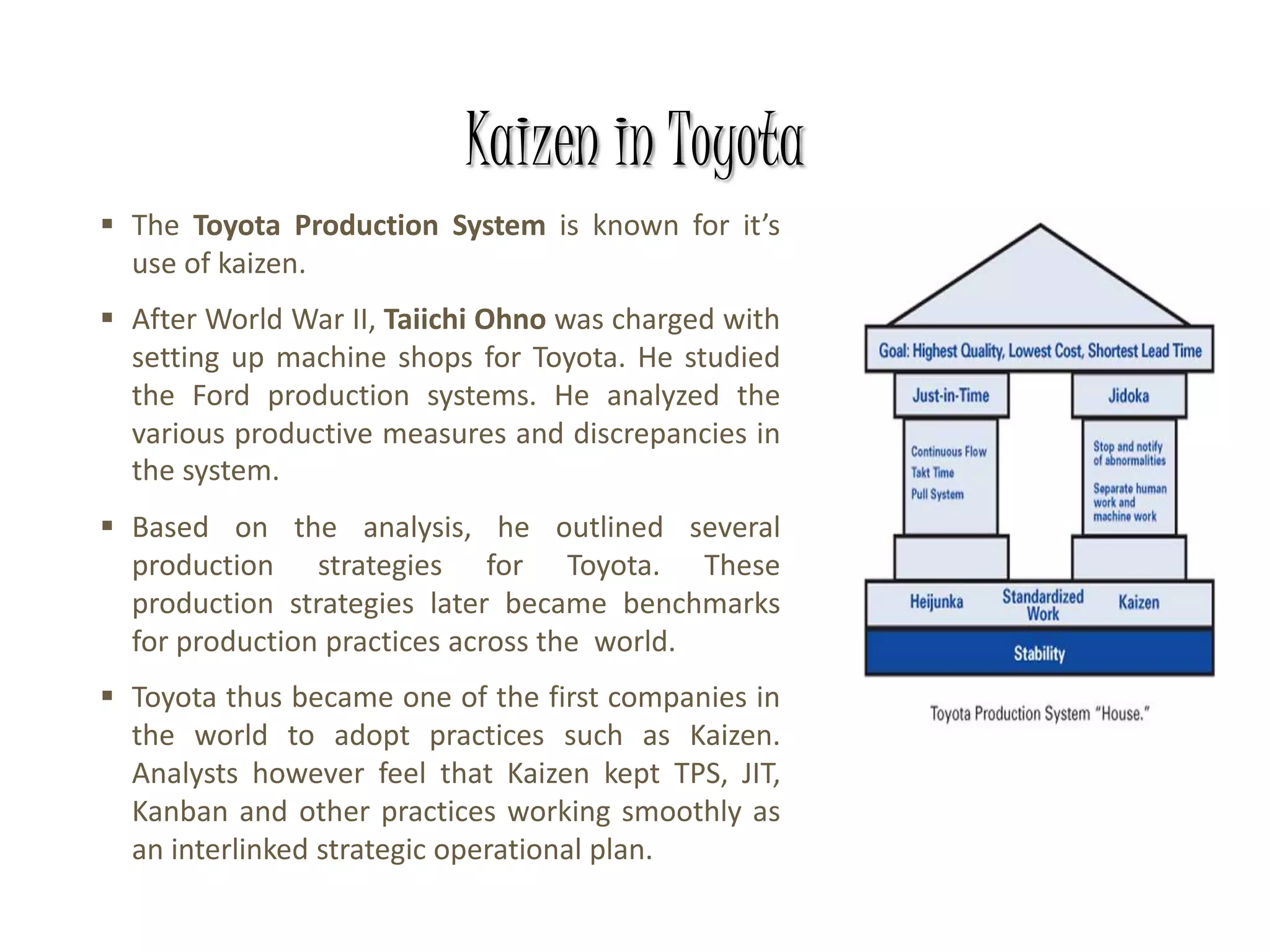

- It originated in postwar Japan when experts like Deming taught Japanese companies. Toyota widely adopted kaizen to link JIT, kanban and other practices.

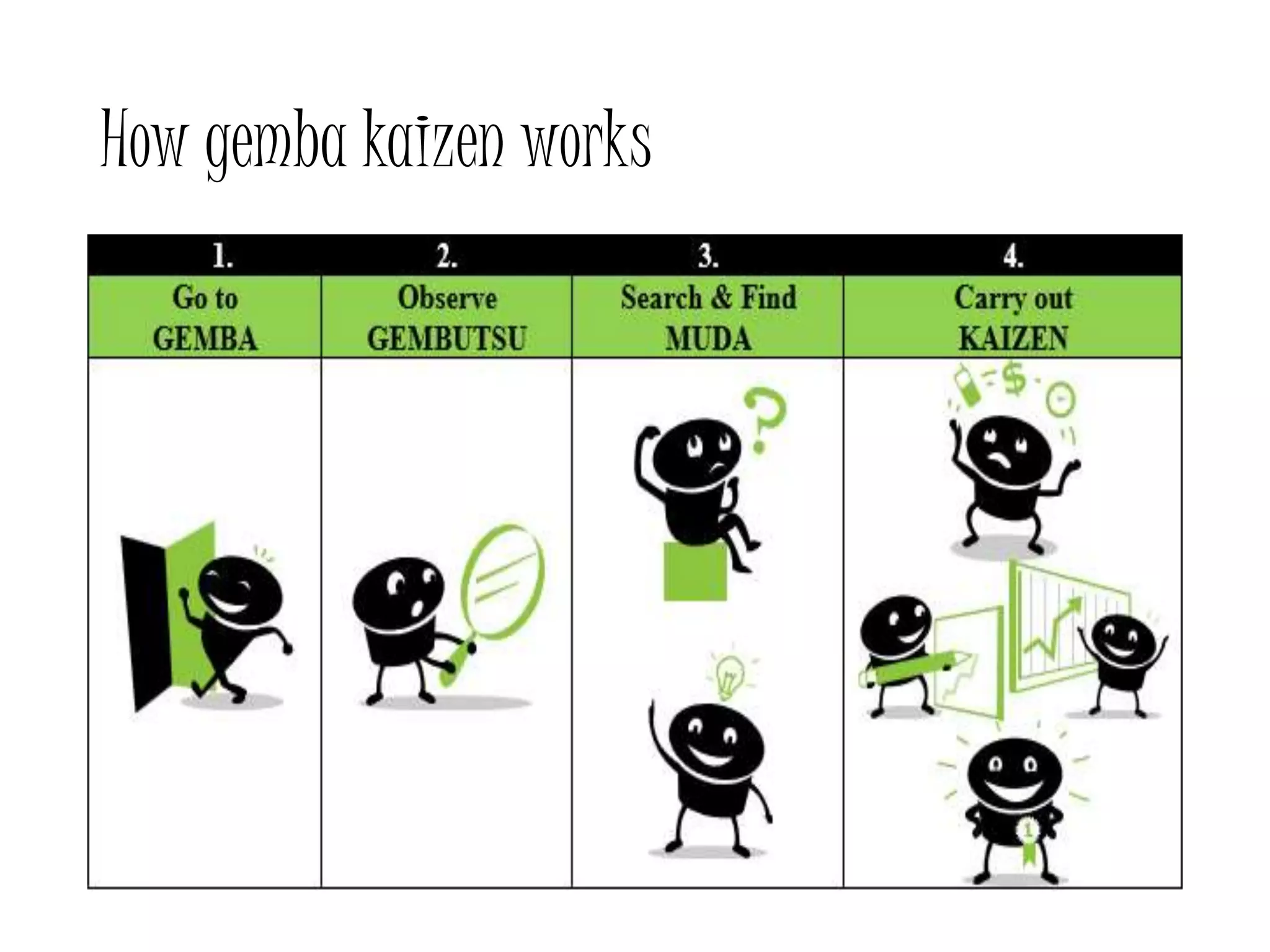

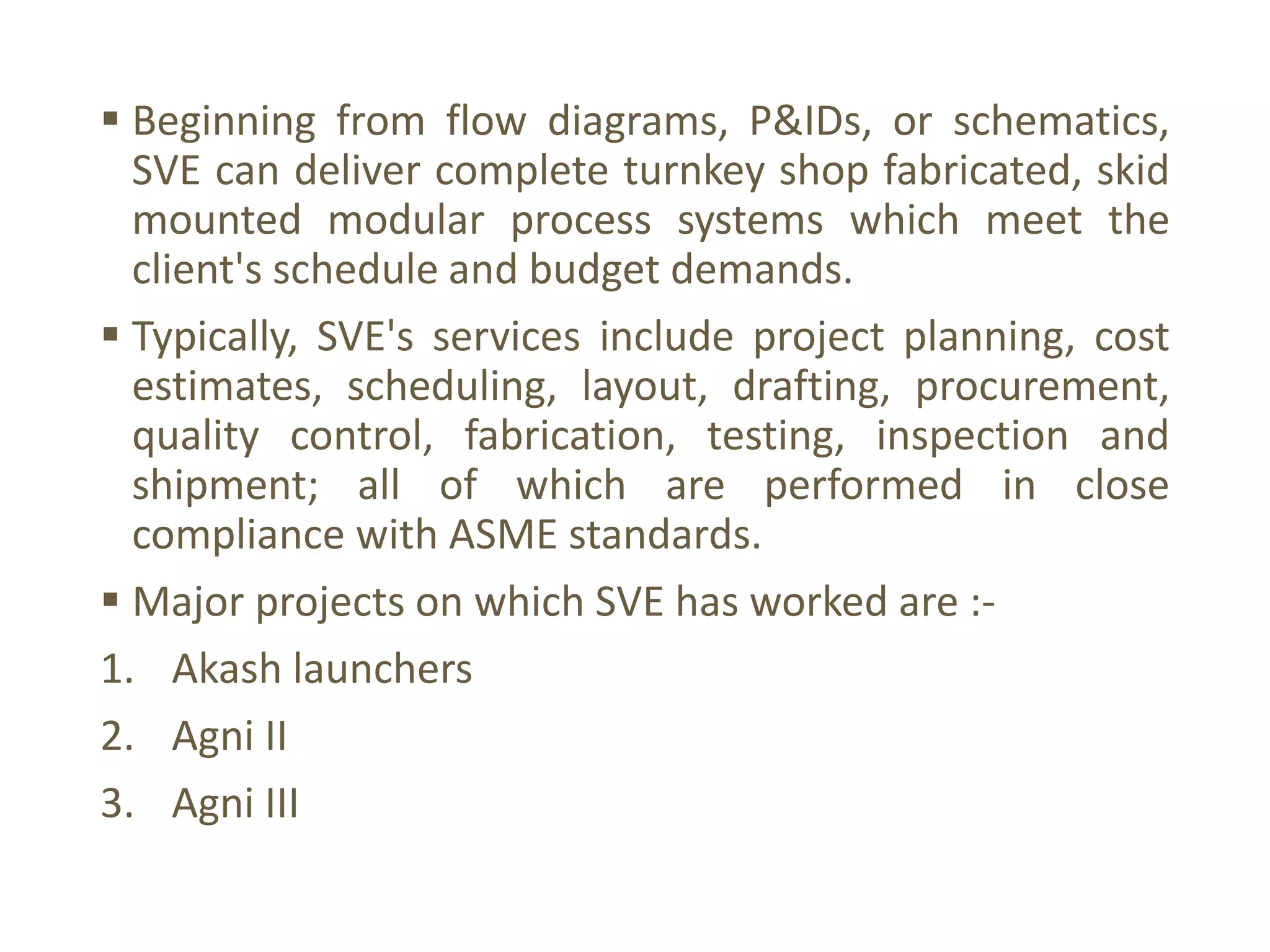

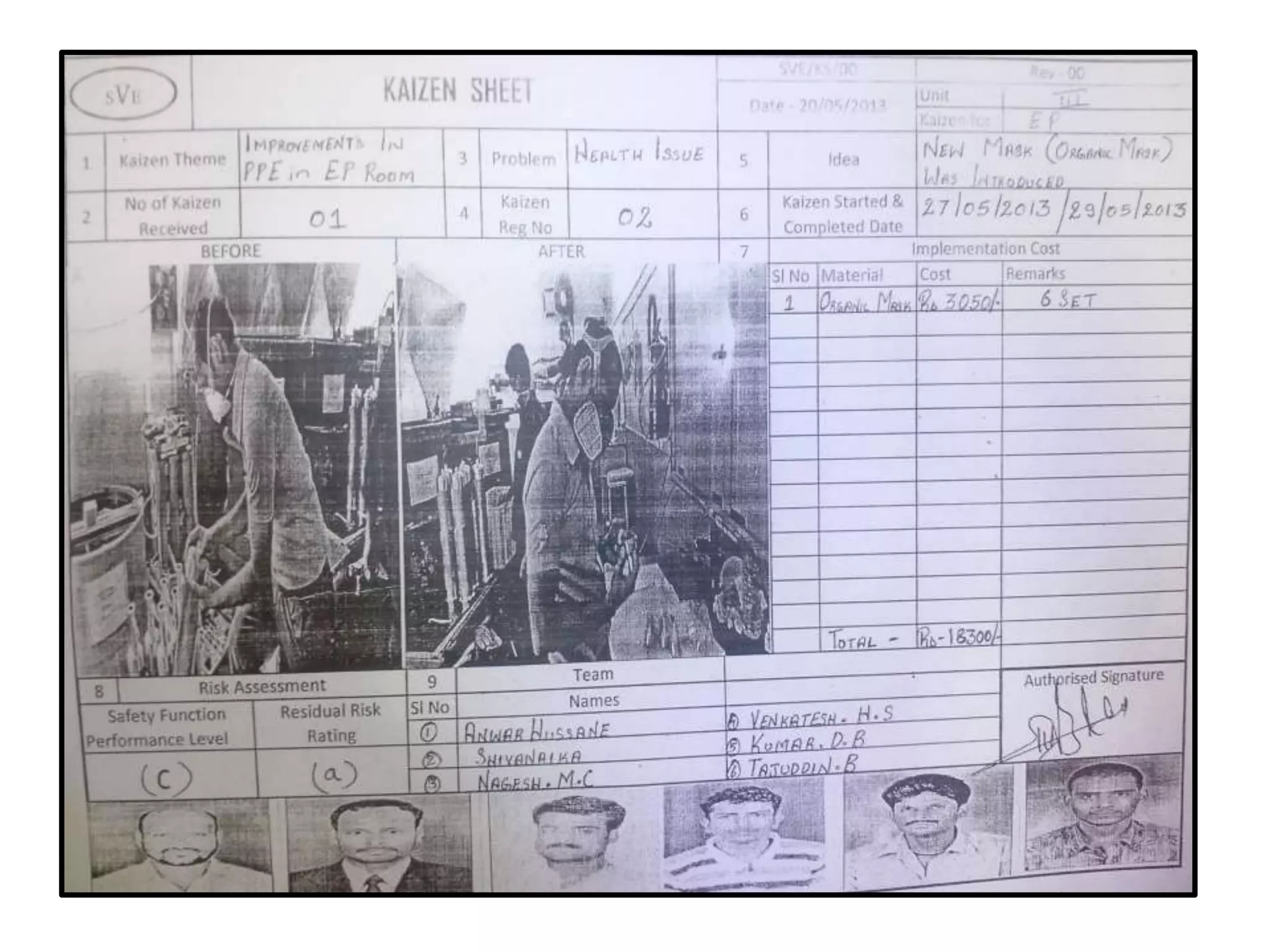

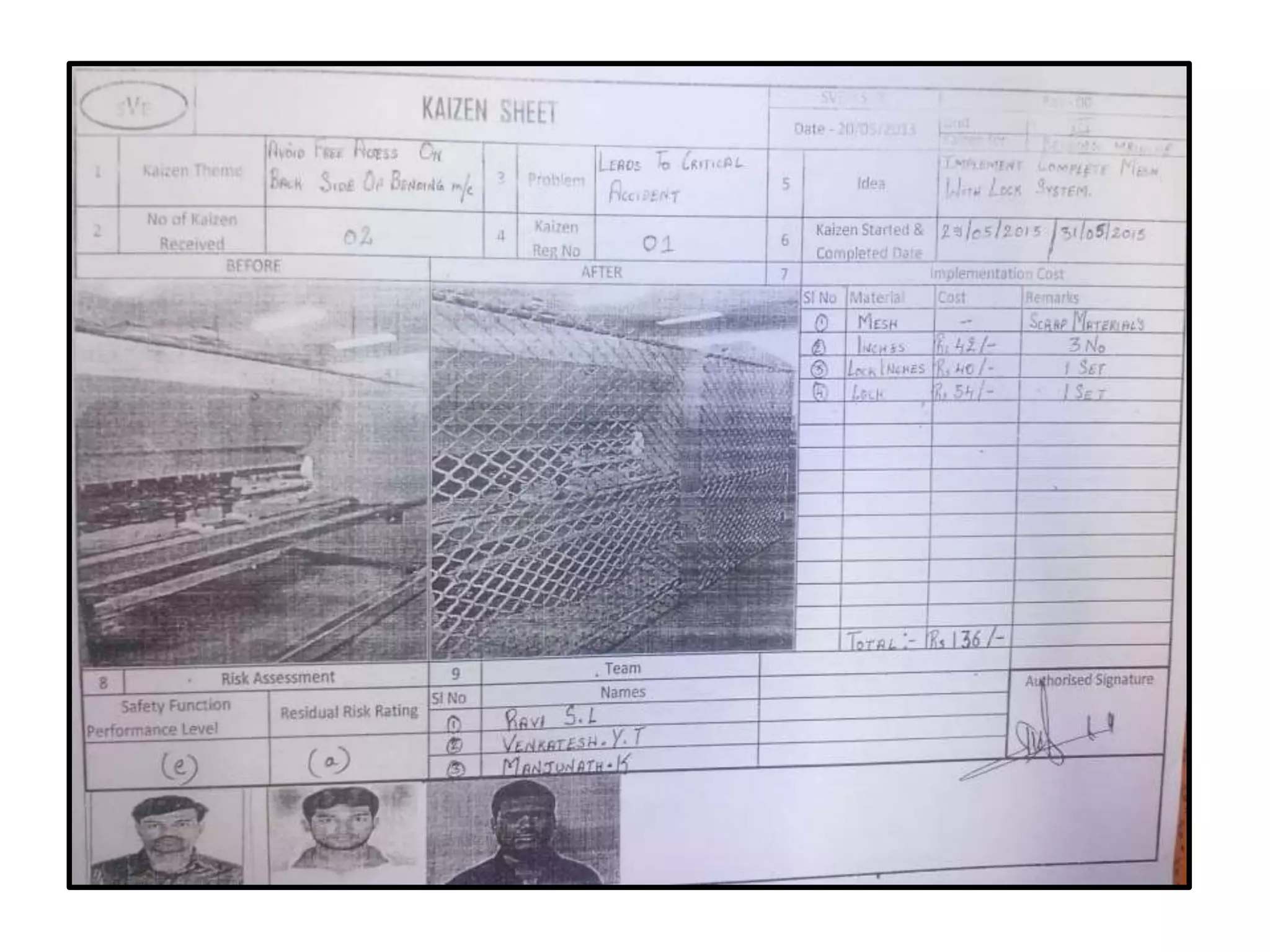

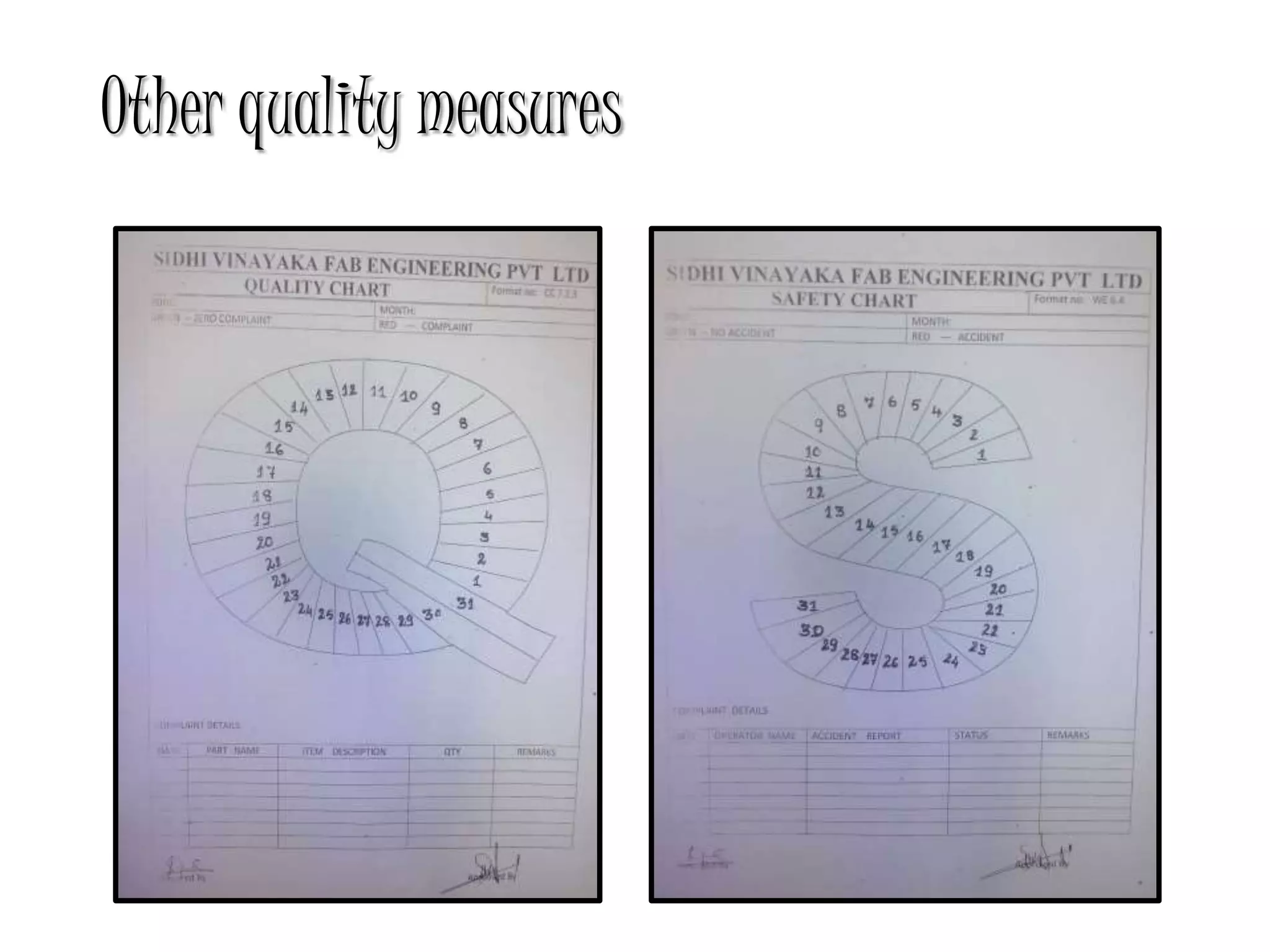

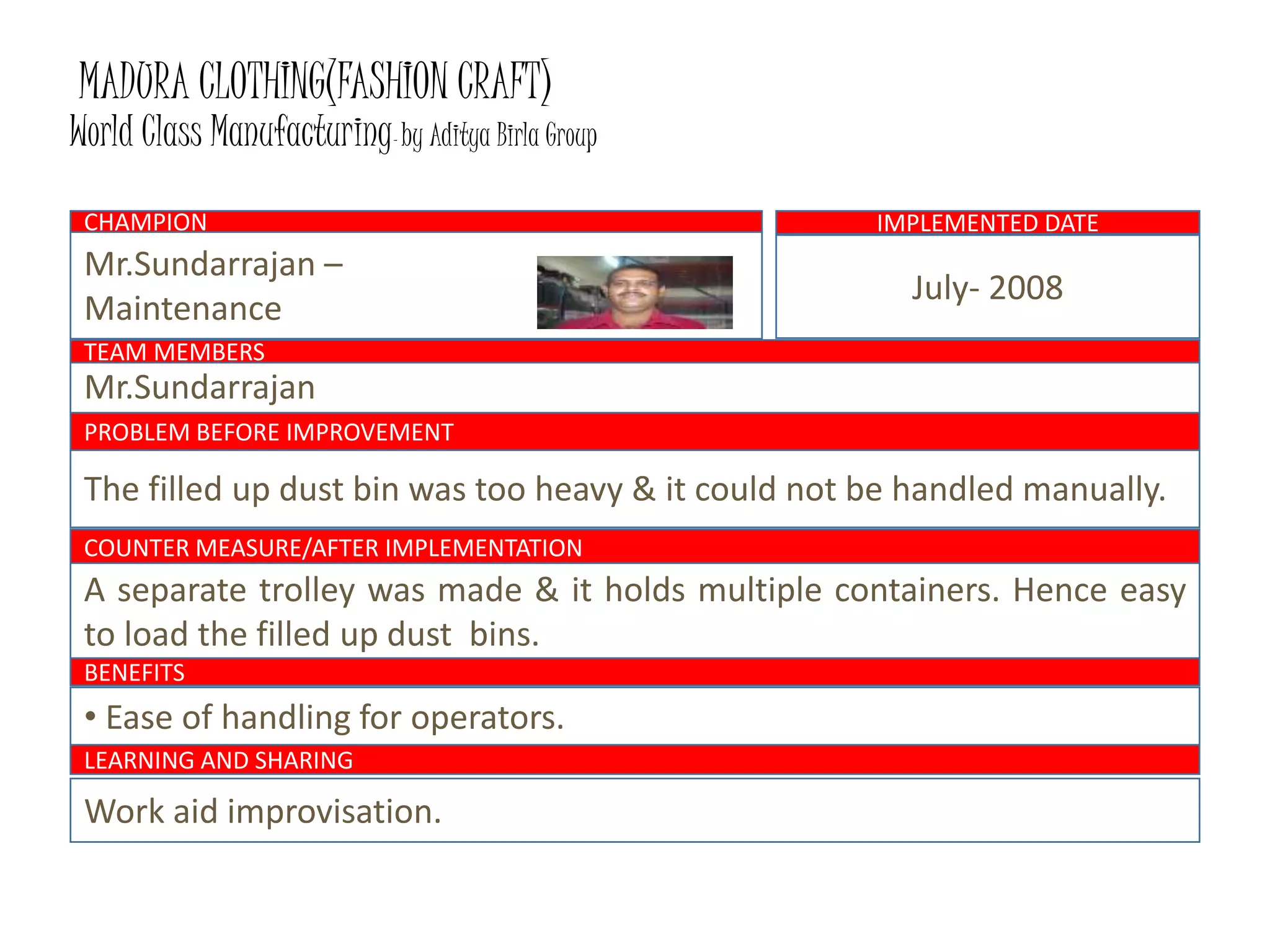

- Kaizen aims to eliminate muri (overburden), mura (unevenness), and muda (waste). Case studies show how companies like Sidhi Vinayak Fab and Madura Fashion implemented kaizen to improve processes.

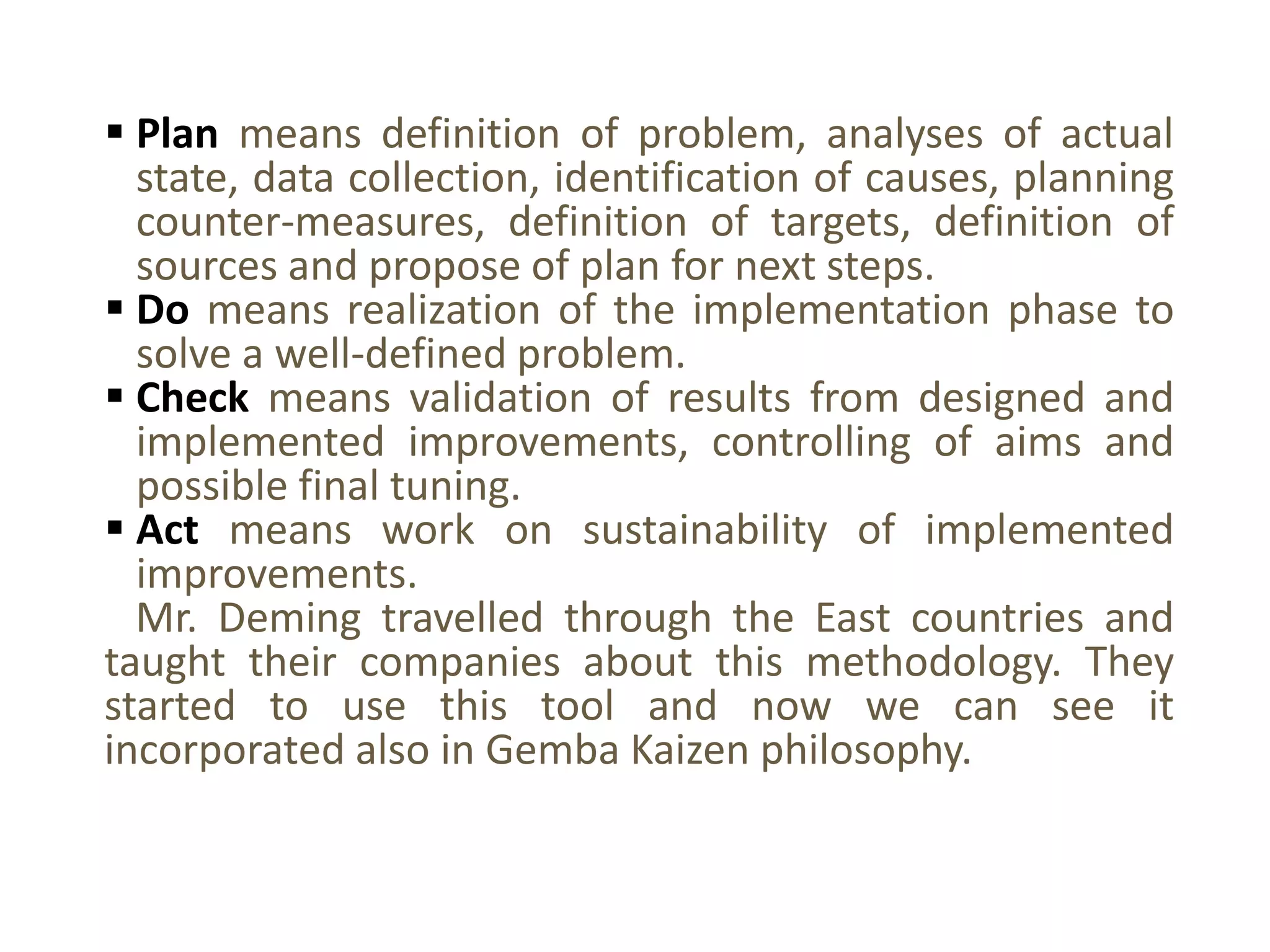

- Kaizen is an ongoing process using techniques like PDCA cycles and 5