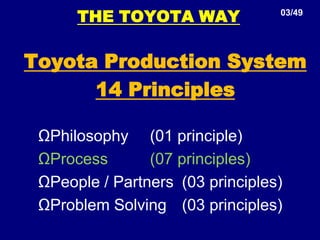

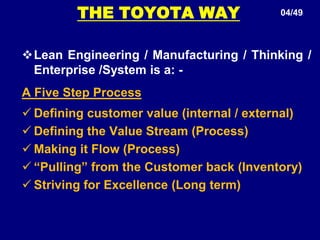

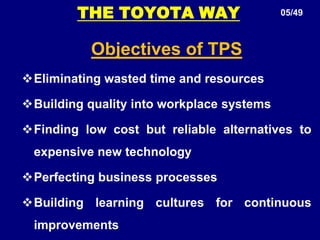

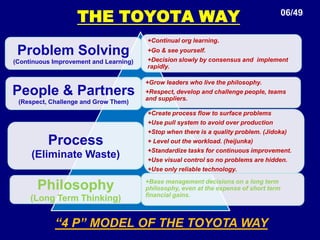

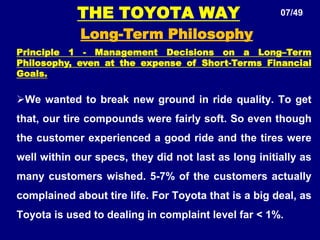

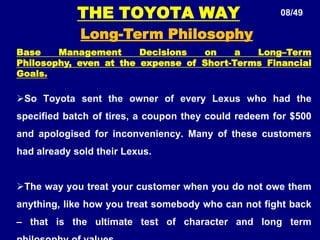

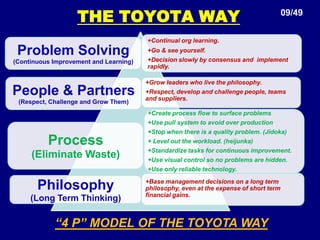

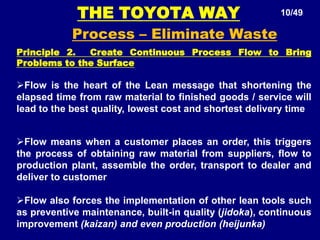

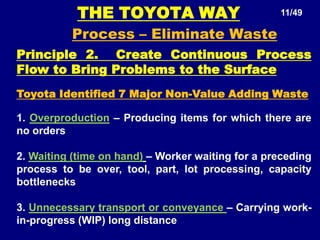

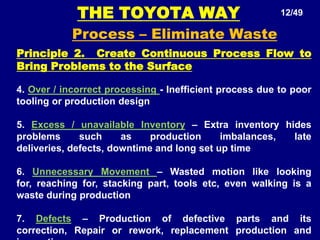

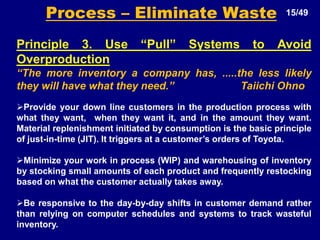

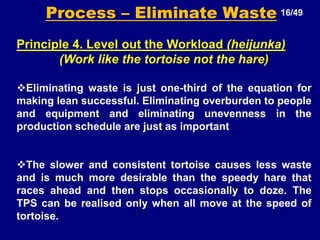

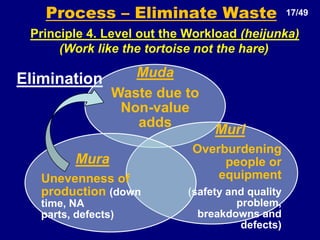

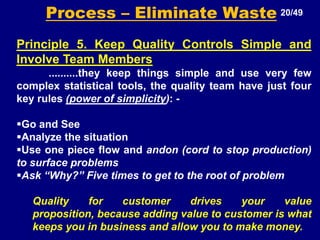

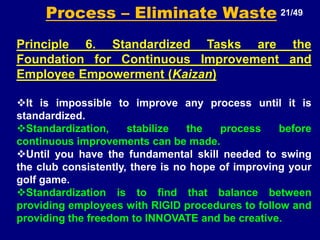

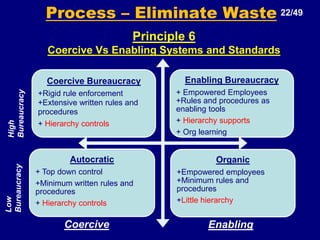

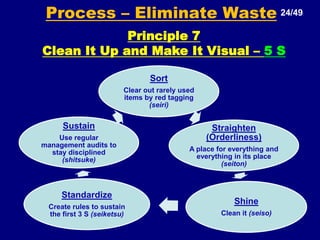

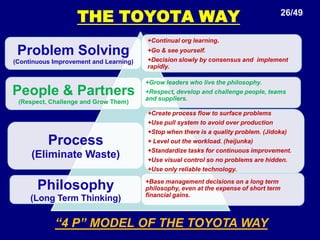

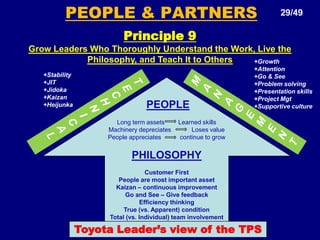

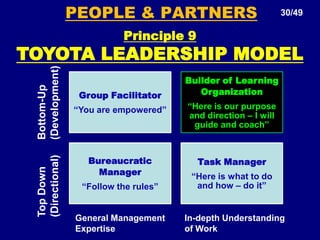

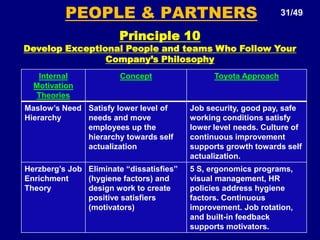

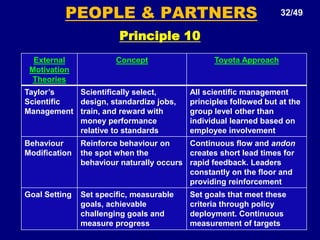

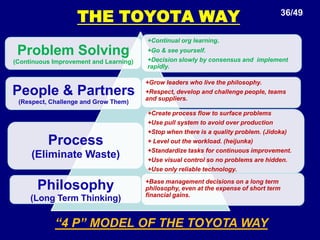

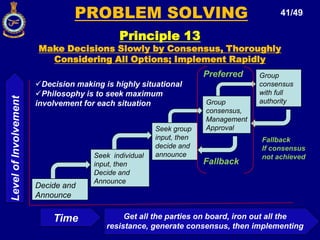

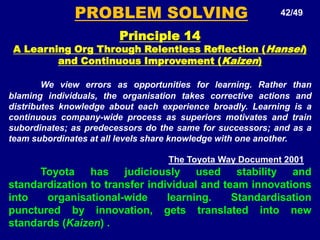

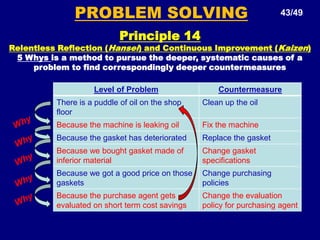

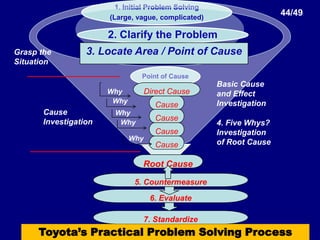

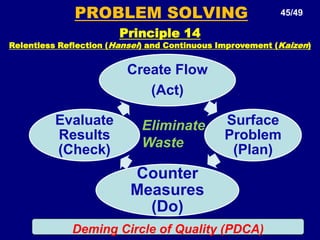

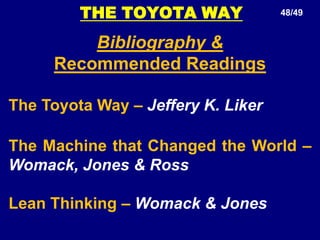

The document outlines the Toyota Production System (TPS) through 14 management principles aimed at maximizing efficiency and quality in manufacturing. Key principles include fostering continuous improvement, implementing standardized tasks, leveraging visual controls, and emphasizing long-term decision-making over short-term financial gains. The philosophy supports treating suppliers as partners and encourages deep observation of processes to understand and resolve issues effectively.