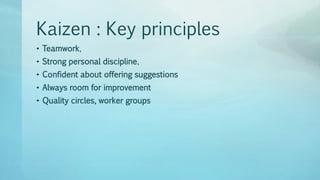

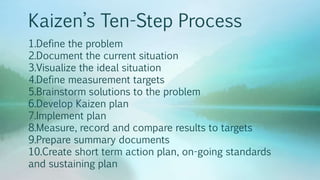

Kaizen is a Japanese philosophy of continuous improvement involving all employees. It focuses on teamwork, personal discipline, and always seeking improvement. Key concepts of Kaizen include quality circles, the PDCA cycle, 5S methodology, JIT, and kanban. Toyota widely implemented Kaizen principles to achieve production efficiencies through standardized processes, reduced waste, and continuous incremental improvements. Kaizen events provide a structured but lightweight approach to process improvement through defining problems, measuring current performance, developing solutions, implementing plans, and standardizing successful changes.