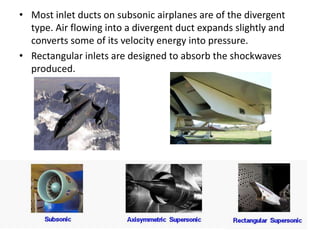

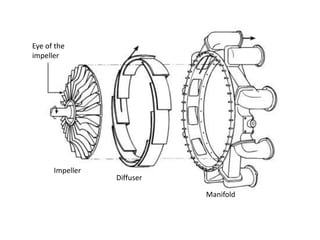

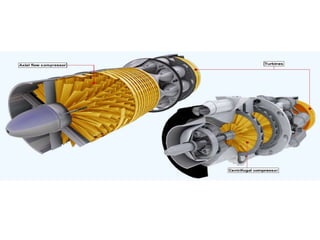

The document provides an overview of jet propulsion concepts, including the functions of various engine components like compressors and turbines. It explains the principles of airflow, combustion types, and the role of elements such as afterburners and reverse thrust for improved performance. Key topics include the differences between centrifugal and axial flow compressors, as well as the behavior of air pressure and temperature through the engine process.