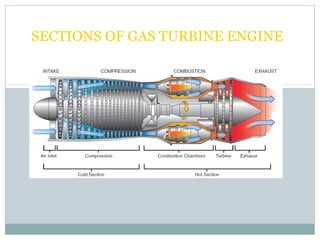

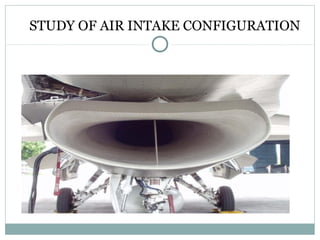

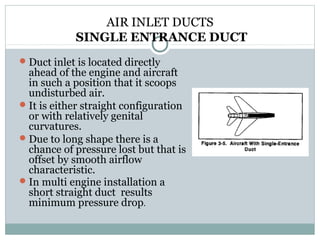

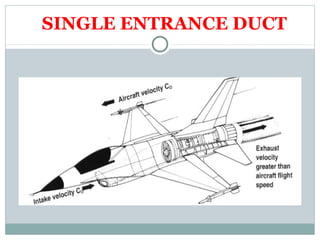

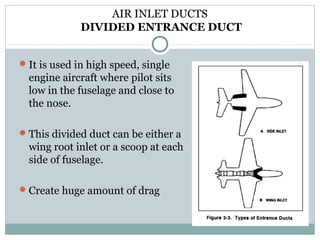

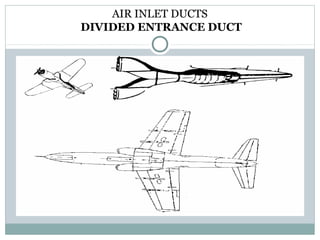

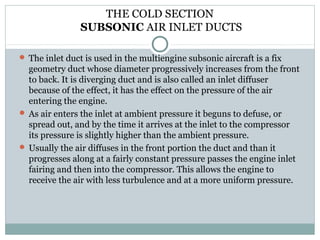

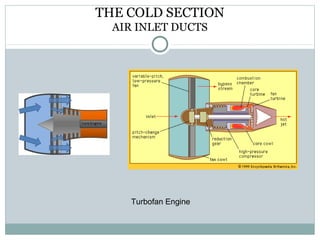

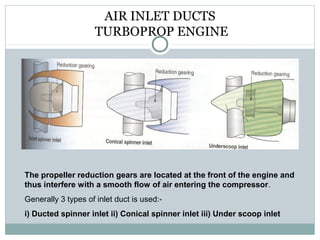

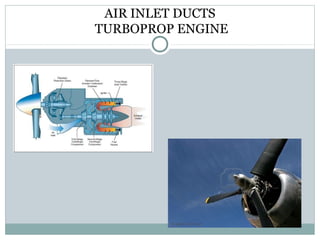

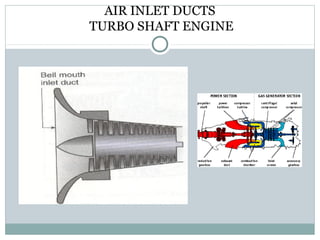

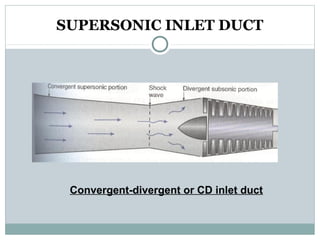

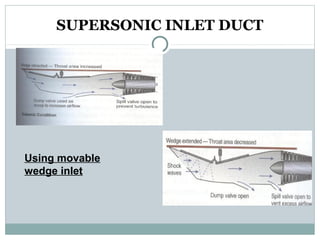

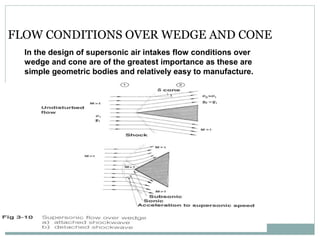

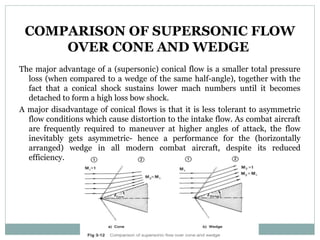

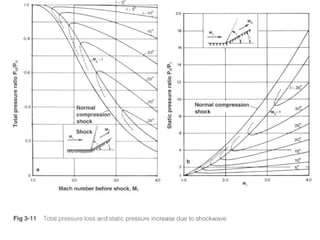

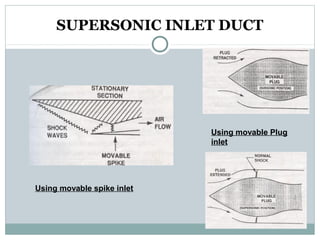

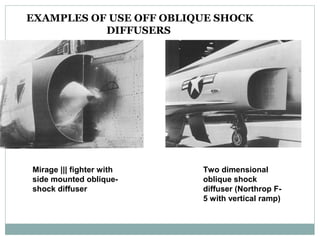

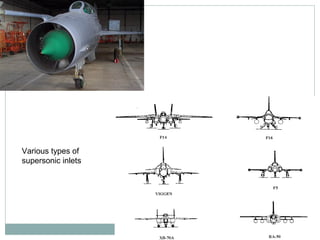

This document discusses the sections and components of gas turbine engines used in aircraft. It describes how gas turbine engines are divided into two main sections - the cold section and the hot section. The cold section contains the air inlet duct, compressor, and diffuser. The hot section contains the combustor, turbine, and exhaust. It also discusses the different types of air inlet ducts used for subsonic and supersonic flight, including single entrance, divided entrance, convergent-divergent, and movable spike/plug designs.